What Is Galvanized steel Piping?

Galvanised Iron (GI) Pipes are manufactured using mild steel strips of Low Carbon steel Coils. The strips are passed through a series of fin rolls to give them a circular shape. The slit ends of the strips are then welded together by continuously passing high frequency electric current across the edges. The welded steel pipes are then passed through sizing sections where any dimensional deviations are corrected. The pipes are then cut into desired lengths by automatic cutting machines. The tubes are then pressure tested for any leaks randomly. The galvanization and varnishing of pipes are done as per specific requirements.

The GI Pipes are generally used for distribution of treated or raw water in rural or urban areas. These pipes are cheaper, light Weight and easy to handle.

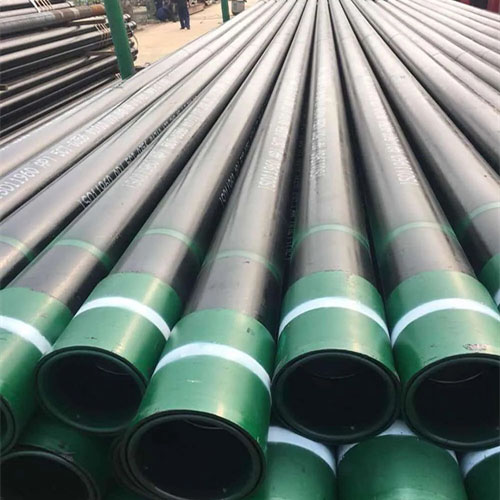

Galvanized steel Pipe with hot-dip or galvanized zinc layer of Welded steel pipe. Galvanized steel pipe can increase Corrosion resistance and prolong service life. Galvanized pipe is widely used, in addition to water, gas, Oil and other general low pressure fluid pipeline pipe, also used for oil industry, especially in the offshore oil well pipe, pipeline, chemical coking equipment oil heater, condensing cooler, coal-water wash oil exchange tube, as well as trestle pipe pile, mining tunnel support frame pipe, etc.

The zinc coating will prevent the steel core from corroding by serving as a protective outer layer. In addition, zinc in low quantities is not toxic to humans, and that makes it an ideal metal for coating water pipes.

Steel is affordable, strong and readily worked by craftsmen, but it will quickly rust if not protected from the effects of moisture. One way to prevent steel from rusting is to immerse it in a hot zinc bath or to attach the zinc via an electroplating process; these processes are known as galvanizing.