24″X6.35MMX20FT BLACK WELD steel TUBES FOR Oil

24″X6.35MMX20FT BLACK WELD STEEL TUBES FOR OIL

| Product | 24″X6.35MMX20FT BLACK WELD STEEL TUBES FOR OIL |

| Standard | ASTM A106 |

| Out Diameter | 1/2″~20″,20mm~508mm |

| Wall thickness | 2.0mm~30mm |

| Material | ASTM A106 GRB |

| Length | 5.8-12m or as customers required |

| Surface treatment | Black,varnish coating or polished |

| Technique | Cold drawn/hot rolled |

| Usage | 1. Low and middle pressure fluid transportation pipeline

2. casing Tube 3. Boiler Pipe 4. Petroleunm and natural gas industry 5. Chemistry industry 6. Electric industry |

| Package | 1. Bundle packing.

2. Bevelled end or Plain end or warnished as per buyer’s required. 3. Marking: as per customer’s requests. 4. Painting varnish coating on the pipe. 5. Plastic caps at ends. |

ZS Steel Pipe is one of the pioneer brand in China sector and provide superb quality line of ASTM A106 Grade B Carbon steel Pipe.We have meticulous processes which help transform processes, improve efficiencies & enhance customer experience. We provide our clients with extremely competitive pricing & best delivery time, which leads to 100% satisfaction. We entertain both kind of orders of Hot rolled carbon steel pipe or tube .

E.g. small & big orders with equal priority. Our competitive pricing has enabled to capture clients around the world in a short span of time. Pricing is always rock bottom for all orders. We aim to maximize our conversion rate to enter as a vendor in companies, and thus leave no stone unturned to make sure the order is bagged by us. Exports have gained prominence at ZS Steel Pipe. We have executed export orders of ASTM A106 Grade B Carbon Steel Pipe for clients in more than 58 countries so far. The number and volumes continue to increase.

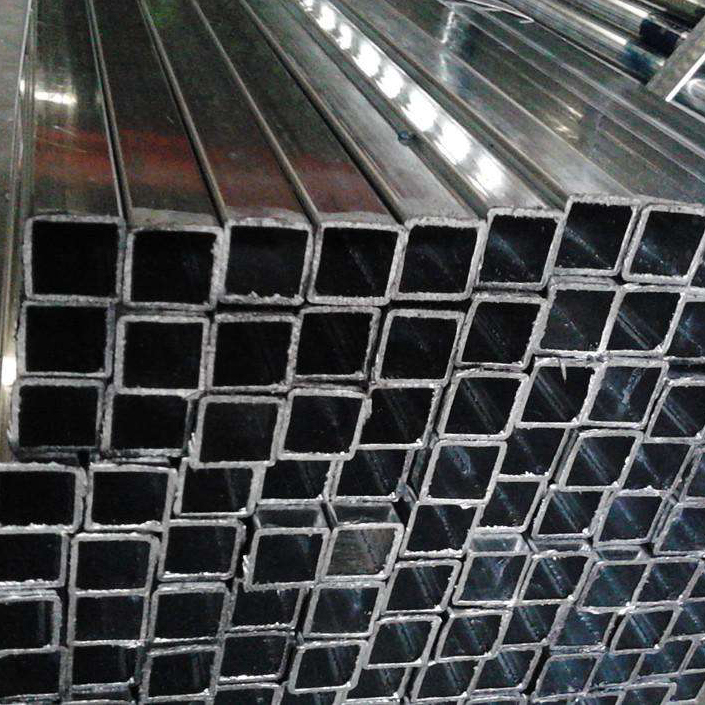

Related Products:Galvanized Steel Pipes