ASTM A213 Seamless Steel Pipe

QUALITY ASSURANCE :

- All products are produced by large factories

- Professional quality inspection tracking team

- Can accept any third party inspection

- Accept third party supervision

ASTM A213 Seamless steel Pipe

ASTM A213 Seamless Steel Pipe, seamless ferritic and austenitic alloy-steel boiler superheater and heat exchanger tubes broadly utilized in overheated boiler, seamless steel pipes heat exchanger tubes.

This specification covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes. Grades containing the letter H in their designation have requirements different from those of similar grades not containing the letter H. These different requirements provide higher creep-rupture strength than normally achievable in similar grades without these different requirements. The tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified. Grade TP347HFG shall be cold finished. Heat treatment shall be done separately and in addition to heating for hot forming. The ferritic alloy and ferritic stainless steels shall be reheated. On the other hand, austenitic Stainless steel tubes shall be furnished in the heat-treated condition. Alternatively, immediately after hot forming, while the temperature of the tubes is not less than the minimum solution temperature, tubes may be individually quenched in water or rapidly cooled by other means. Tension test, Hardness test, flattening test, and flaring test shall be done to each tube. Also, each tube shall be subjected to the nondestructive electric test or hydrostatic test.

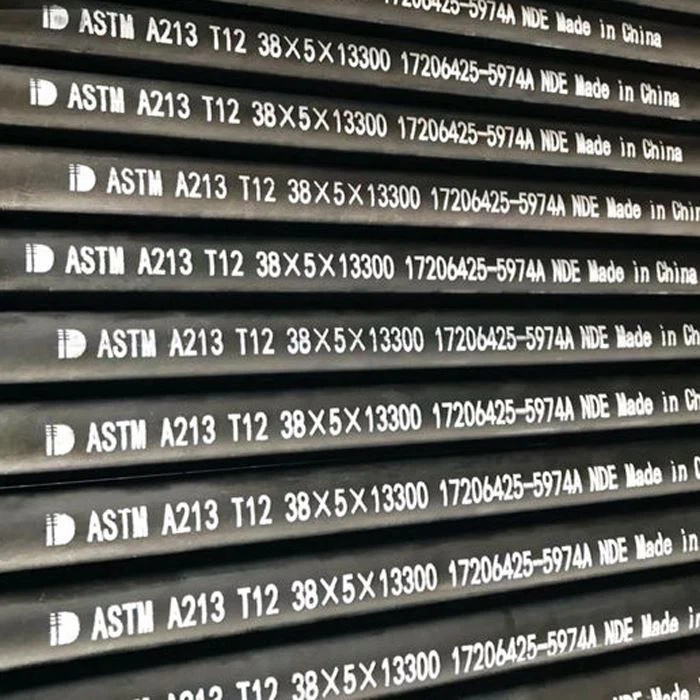

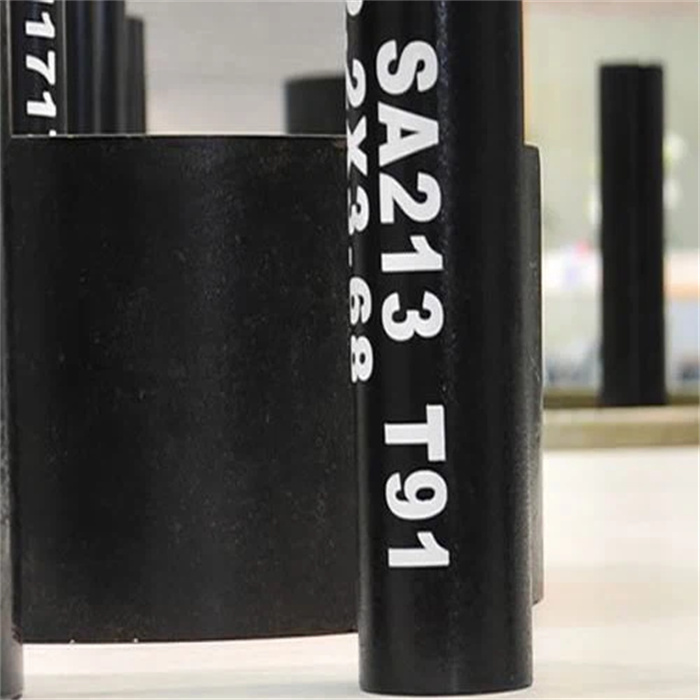

Alloy steel Pipe Specifications:

| Standard Specifications for Seamless Ferritic and Austenitic Alloy-Steel for boilers, superheaters, and heat-exchangers | |

| Applications: | For manufacturing wall panel,economizers, superheaters and steam pipelines for boilers |

| Size (mm): | O.D.: 28-168; W.T.: 2∼30; L: max 12000 |

Grade and Chemical Composition (%)

| Grade | C | Mn | P≤ | S≤ | Si | Cr | Mo |

| T11 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50-1.00 | 0.50-1.00 | 1.00-1.50 |

| T12 | 0.05-0.15 | 0.30-0.61 | 0.025 | 0.025 | ≤0.50 | 0.80-1.25 | 0.44-0.65 |

| T13 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | ≤0.50 | 1.90-2.60 | 0.87-1.13 |

Mechanical properties(MPa):

| Grade | Tensile Point | Yield Point |

| T11 | ≥415 | ≥205 |

| T12 | ≥415 | ≥220 |

| T13 | ≥415 | ≥205 |

Our company is specialized in steel pipe and pipe fitting for many years, with best quality,best service and competitive price.The products can be provided as you need , the best offer will send to you !More services we can provide:

1.Professional Free Design

2.Low MOQ

3.Fast Delivery

4.Free Sample

5.High Quality