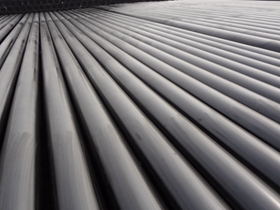

Multi-Lead Rifled Seamless steel tube For High-Pressure Boiler

Applications: The rifled tubes are served in super/ultra super critical water wall panels over 300,000KW of boiler, chemical, electricity industries.

Thchnical speifications

ASME SA192, SA209, SA210, SA213, EN 10216, DN 17175, BS 3059, JIS 3461,JIS 3462.

Type: Type A, Type B, and Optimized Type.

Manufacturing method: Cold-drawn

Delivery Conditions: Normalized and Tempered

Steel grade

ASTM A192,ASTM A210 Gr.A1,Gr.C,

ASTM A209 T1,ASTM A213 T2,T5,T9,T11,T12,T22,T23,T91,T92 ST45.8/III

MATERIALS: All our steel is melted in-house through electric arc furnace route, than is ladle refined, 100% vacuum degassed, continuous cast and rolled.

Size

Type A: OD28.6mm-76.2mm, WT6.38mm-18.33mm

Type B: OD35mm-66.7mm, WT7.2mm-8.55mm

No. of Ribs:12 max.

Max Length: 26mtr

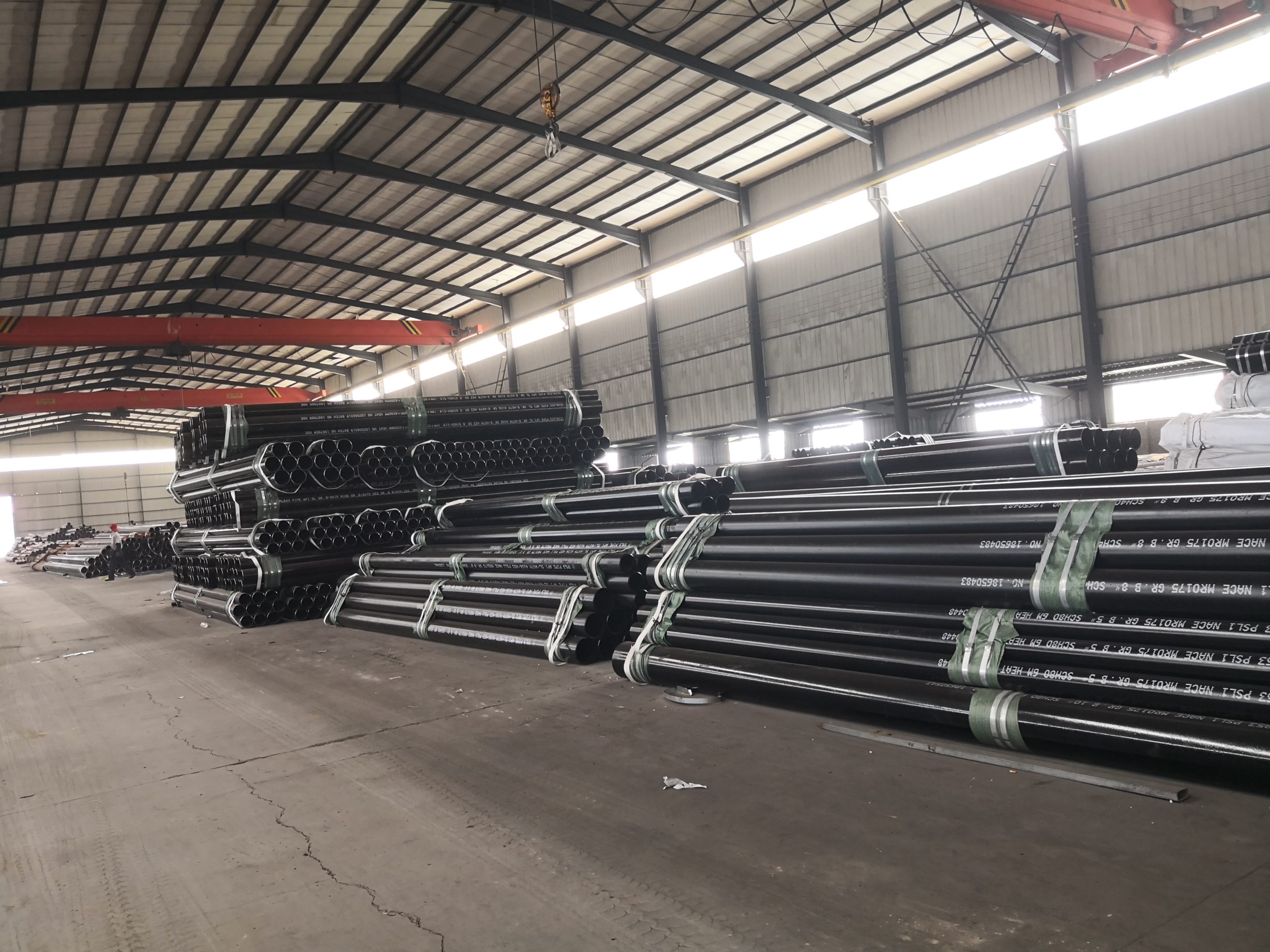

Package

Hexagonal bundles, strapped, both ends protected with plastic net Or wooden boxes according to length and destination Oiled inside / outside

Marking, Oil-coating,varnish,end-protection by plastic caps to be confirmed.

Tolerances for dimensions and thread parameters of internal thread

size:od:28.6mm-121mm wt:5.1mm–16mm

| Code | size | “A”Allowable deviation of type | “B”Allowable deviation of type |

| A | OD:OD≤38.1 mm | ±0.15 mm | — |

| 38.1<OD<50.8 mm | ±0.20 mm | ||

| 50.8mm≤OD<63.5 mm | ±0.25 mm | ||

| OD≥63.5 mm | ±0.30 mm | ||

| B | OD:OD≤38.1 mm | — | ±0.15 mm |

| 38.1<OD<50.8 mm | ±0.20 mm | ||

| 50.8≤OD<63.5 mm | ±0.25 mm | ||

| OD≥63.5 mm | ±0.30 mm | ||

| C | Thread root diameter

:OD-(1.11×Minimum Wall thickness×2) |

||

| OD≤38.1mm | ±0.15 mm | ±0.15 mm | |

| 38.1<OD<50.8 mm | ±0.20 mm | ±0.20 mm | |

| 50.8≤OD<63.5 mm | ±0.25 mm | ±0.25 mm | |

| OD≥63.5 mm | ±0.30 mm | ±0.30 mm | |

| E | Minimum diameter

|

Negative deviation

0 |

Negative deviation

0 |

| F | Minimum wall thickness

|

22% | 22% |

| 0 | 0 | ||

| G | Number of threads | — | — |

| I | Thread width: | — | — |

| J a | Thread height:OD≤38.1 mm | ±0.3 mm | ±0.18 mm |

| 38.1<OD<50.8 mm | ±0.20 mm | ||

| 50.8≤OD<63.5 mm | ±0.23 mm | ||

| OD≥63.5 mm | ±0.28 mm | ||

| K | Side angle of thread | ±15° | ±15° |

| O | Fillet radius | — | — |

| M | Pitch of thread | ±3.2 mm | ±3.2 mm |

| N | Thread lead | ±3.2 mm×Number of threads | ±3.2 mm×Number of threads |

| Q b | Spiral angle | rating | rating |

| T | Top width (axial) | ±1.3 mm | ±1.3 mm |

| U | Top (axial) groove width | — | — |

| a YES“B”The maximum deviation of any thread height can exceed the allowable deviation value specified in the table, but shall not exceed the allowable deviation of 0.08 mm, and the average height of all threads shall be in accordance with the given deviation range | |||

| b The rating is based on the axis of the Pipe | |||