Benefits of Using ERW Cold Rolled Stainless steel Pipe for Industrial Applications

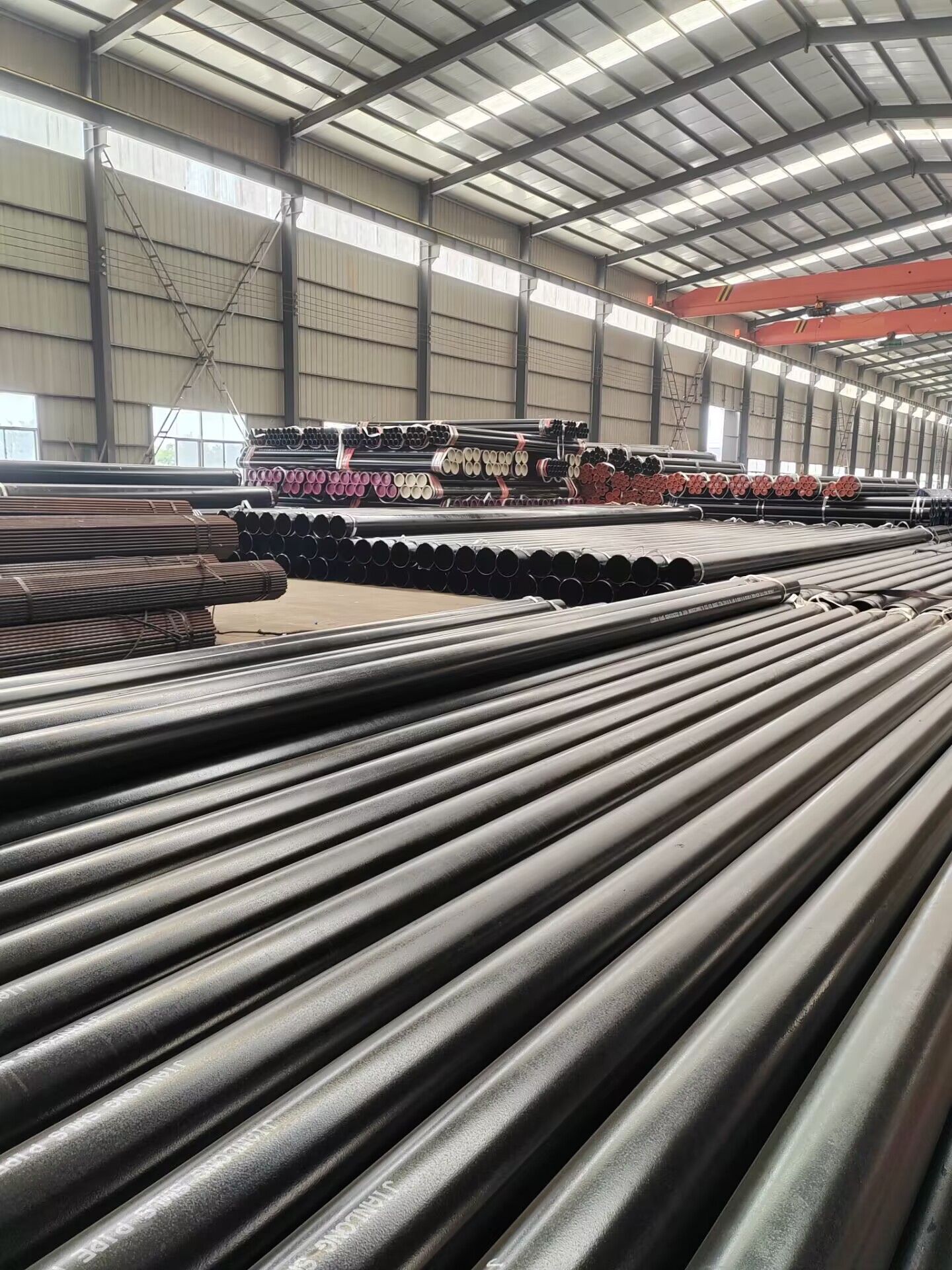

Stainless steel is a versatile Material that is widely used in various industries due to its durability, Corrosion resistance, and aesthetic appeal. When it comes to choosing the right type of stainless steel pipe for industrial applications, ERW cold rolled stainless steel pipe is a popular choice. This type of pipe is known for its high-quality finish, tight tolerances, and uniformity, making it ideal for a wide range of applications.

One of the key benefits of using ERW cold rolled stainless steel pipe is its superior surface finish. The Cold rolling process used to manufacture these pipes results in a smooth, polished surface that is free from imperfections such as pits, scratches, and rough spots. This not only enhances the aesthetic appeal of the pipe but also improves its corrosion resistance and longevity.

In addition to its superior surface finish, ERW cold rolled stainless steel pipe is known for its tight tolerances and uniformity. The cold rolling process allows for precise control over the dimensions of the pipe, ensuring that it meets the required specifications for a particular application. This level of precision is essential in industries where consistency and accuracy are paramount, such as in the manufacturing of automotive components, machinery, and equipment.

Another advantage of using ERW cold rolled stainless steel pipe is its strength and durability. Stainless steel is inherently strong and resistant to corrosion, making it an ideal material for applications that require high levels of durability and reliability. The cold rolling process further enhances the strength of the pipe, making it capable of withstanding high pressure, temperature, and mechanical stress without deforming or failing.

Furthermore, ERW cold rolled stainless steel pipe is easy to work with and can be customized to meet specific requirements. It can be easily welded, bent, and fabricated into various shapes and sizes, making it suitable for a wide range of applications. Whether you need round, square, or rectangular pipes, ERW cold rolled stainless steel pipe can be tailored to fit your exact specifications.

In conclusion, ERW cold rolled stainless steel pipe offers a range of benefits that make it an excellent choice for industrial applications. From its superior surface finish and tight tolerances to its strength, durability, and versatility, this type of pipe is well-suited for a variety of industries. Whether you are in the automotive, construction, or manufacturing sector, ERW cold rolled stainless steel pipe can provide the reliability and performance you need for your projects. Consider using this high-quality material for your next industrial application and experience the many advantages it has to offer.

Step-by-Step Guide to Polishing Stainless steel pipes for a Professional Finish

Stainless steel pipes are a popular choice for a variety of applications due to their durability, corrosion resistance, and aesthetic appeal. Whether you are working on a DIY project or a professional job, polishing stainless steel pipes can give them a sleek and professional finish. In this step-by-step guide, we will walk you through the process of polishing ERW cold rolled round/square/rectangular Seamless stainless steel pipes to achieve a flawless result.

Before you begin the polishing process, it is important to gather all the necessary materials and tools. You will need a polishing compound, a polishing wheel or buffing pad, a drill or polishing machine, safety goggles, gloves, and a clean cloth. Make sure to work in a well-ventilated area and wear protective gear to prevent any accidents.

Start by cleaning the stainless steel pipe thoroughly to remove any dirt, grease, or debris. Use a mild detergent or stainless steel cleaner and a soft cloth to wipe down the surface. Rinse the pipe with clean water and dry it with a clean cloth to ensure that it is free of any residue.

Next, apply a small amount of polishing compound to the surface of the stainless steel pipe. You can choose from a variety of polishing compounds, such as metal polish or stainless steel polish, depending on the level of shine you want to achieve. Use a clean cloth to spread the polishing compound evenly over the surface of the pipe.

Once the polishing compound is applied, it is time to start buffing the stainless steel pipe. Attach a polishing wheel or buffing pad to a drill or polishing machine and set it to a low speed. Gently move the polishing wheel or buffing pad back and forth along the Length of the pipe, applying light pressure to ensure an even finish.

As you buff the stainless steel pipe, you will start to see the shine and luster of the metal come through. Continue buffing until you achieve the desired level of polish. If necessary, you can apply more polishing compound and buff the pipe again to enhance the shine.

After you have finished buffing the stainless steel pipe, use a clean cloth to wipe away any excess polishing compound and reveal the polished surface underneath. Inspect the pipe for any areas that may need additional polishing and touch them up as needed.

Finally, once you are satisfied with the level of polish on the stainless steel pipe, give it a final wipe down with a clean cloth to remove any remaining residue. Your ERW cold rolled round/square/rectangular seamless stainless steel pipe is now polished and ready for use in your project.

In conclusion, polishing stainless steel pipes is a simple yet effective way to enhance their appearance and create a professional finish. By following this step-by-step guide and using the right materials and tools, you can achieve a flawless polish on your ERW cold rolled round/square/rectangular seamless stainless steel pipes. Whether you are working on a DIY project or a professional job, polishing stainless steel pipes will give them a sleek and polished look that will impress your clients and colleagues.