Benefits of Using SA516 Grouting Alloy steel Pipe in Geological Drilling

Geological drilling is a crucial process in various industries, including mining, Oil and gas exploration, and geothermal energy production. The success of these drilling operations depends on the quality and durability of the equipment used, particularly the steel pipes that are essential for extracting core samples and conducting other drilling activities. One type of steel pipe that has gained popularity in recent years for its superior performance in geological drilling is the SA516 grouting alloy steel pipe.

SA516 grouting alloy steel pipe is a specialized type of steel pipe that is specifically designed for use in high-pressure and high-temperature environments, making it ideal for geological drilling applications. This type of steel pipe is made from a combination of Carbon steel and alloying elements such as chromium, molybdenum, and nickel, which enhance its strength, Corrosion resistance, and overall performance.

One of the key benefits of using SA516 grouting alloy steel pipe in geological drilling is its exceptional durability and resistance to corrosion. Geological drilling operations often involve exposure to harsh environmental conditions, such as high temperatures, corrosive fluids, and abrasive materials. SA516 grouting alloy steel pipe is specifically engineered to withstand these challenging conditions, ensuring that it can perform reliably and effectively over an extended period of time.

In addition to its durability, SA516 grouting alloy steel pipe also offers superior performance in terms of pressure resistance. Geological drilling operations typically involve the use of high-pressure fluids to facilitate the drilling process and extract core samples from the earth. SA516 grouting alloy steel pipe is designed to withstand these high-pressure conditions without compromising its structural integrity, making it a reliable and safe choice for geological drilling applications.

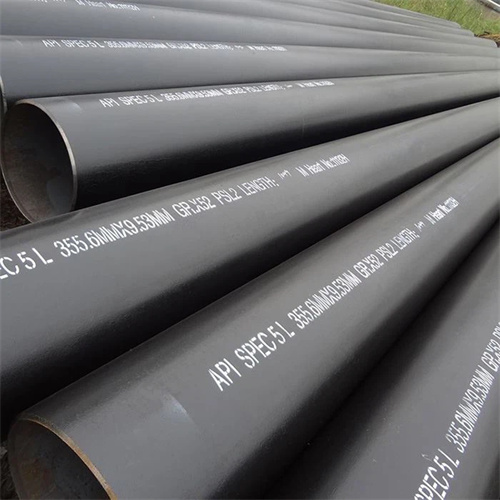

Furthermore, SA516 grouting alloy steel pipe can be customized to meet specific requirements and specifications, making it a versatile option for a wide range of geological drilling projects. Whether you need a DN65 Sch40 carbon Seamless Steel tube or any other specification, SA516 grouting alloy steel pipe can be tailored to meet your exact needs, ensuring optimal performance and efficiency in your drilling operations.

Another advantage of using SA516 grouting alloy steel pipe in geological drilling is its cost-effectiveness. While the initial investment in high-quality steel pipes may be higher than that of standard carbon steel pipes, the long-term benefits of using SA516 grouting alloy steel pipe far outweigh the upfront costs. Its durability and resistance to corrosion mean that it requires less frequent maintenance and replacement, saving you time and money in the long run.

galvanised square tubeIn conclusion, SA516 grouting alloy steel pipe offers a range of benefits for geological drilling applications, including exceptional durability, pressure resistance, customization options, and cost-effectiveness. By choosing SA516 grouting alloy steel pipe for your drilling operations, you can ensure reliable performance, safety, and efficiency in extracting core samples and conducting other drilling activities. Whether you need a DN65 Sch40 carbon seamless steel tube or any other specification, SA516 grouting alloy steel pipe is a reliable and versatile choice for your geological drilling needs.