Advantages of Using API 5L P1 Spiral welded Pipe in Pipeline Construction

API 5L P1 spiral welded pipe is a popular choice in pipeline construction due to its numerous advantages. This type of pipe is known for its high strength and durability, making it ideal for use in demanding applications. In addition, API 5L P1 spiral welded pipe is easy to install and requires minimal maintenance, making it a cost-effective option for many projects.

One of the key advantages of API 5L P1 spiral welded pipe is its high strength. This type of pipe is made from high-quality steel that has been welded in a spiral pattern, which gives it added strength and durability. This makes API 5L P1 spiral welded pipe ideal for use in pipelines that need to withstand high pressure and heavy loads.

Another advantage of API 5L P1 spiral welded pipe is its ease of installation. Because this type of pipe is made in a spiral pattern, it can be easily rolled out and installed in a straight line. This makes the installation process quick and efficient, saving time and labor costs. In addition, API 5L P1 spiral welded pipe can be easily cut to size on-site, making it a versatile option for a wide range of projects.

API 5L P1 spiral welded pipe also requires minimal maintenance, making it a cost-effective choice for many applications. This type of pipe is resistant to corrosion and rust, which helps to extend its lifespan and reduce the need for repairs. In addition, API 5L P1 spiral welded pipe is designed to withstand harsh environmental conditions, making it a reliable option for use in challenging environments.

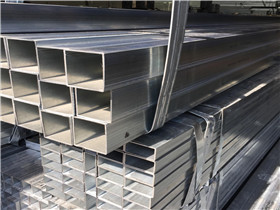

3×3 11 gauge steel

In addition to its high strength, ease of installation, and low maintenance requirements, API 5L P1 spiral welded pipe is also available in a variety of sizes and specifications to meet the needs of different projects. This makes it a versatile option for use in a wide range of applications, from Oil and gas pipelines to water and sewage systems.

Overall, API 5L P1 spiral welded pipe offers numerous advantages for use in pipeline construction. Its high strength, ease of installation, and low maintenance requirements make it a cost-effective and reliable option for many projects. Whether you are building a new pipeline or repairing an existing one, API 5L P1 spiral welded pipe is a versatile choice that can help you get the job done efficiently and effectively.

Comparison of LSAW Steel Pipe and Seamless steel pipe in API 5L X42 Nace MR0175 ASTM36.19 ASTM252 Carbon steel Line Pipe Applications

API 5L P1 Spiral Welded Pipe, LSAW Steel Pipe, and Seamless Steel Pipe are all commonly used in the oil and gas industry for various applications. Each type of pipe has its own unique characteristics and advantages, making it important for companies to understand the differences between them in order to choose the best option for their specific needs.

LSAW Steel Pipe, or Longitudinal Submerged Arc Welded steel pipe, is made by bending and Welding steel plates together to form a pipe. This process results in a strong and durable pipe that is suitable for high-pressure applications. LSAW Steel Pipe is commonly used in the construction of oil and gas pipelines, as well as in the transportation of water and other fluids.

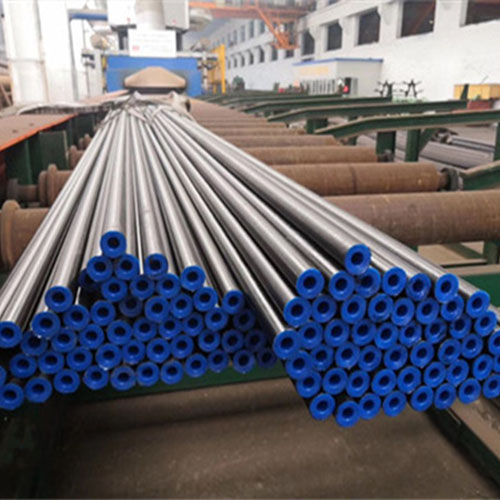

On the other hand, Seamless Steel Pipe is made by piercing a solid steel billet to create a hollow tube. This process results in a pipe that is free of seams, making it ideal for applications that require a high level of precision and reliability. Seamless Steel Pipe is often used in the manufacturing of high-pressure cylinders, hydraulic systems, and other critical components.

When comparing LSAW Steel Pipe and Seamless Steel Pipe in API 5L X42 Nace MR0175 ASTM36.19 ASTM252 Carbon Steel Line Pipe applications, there are several key factors to consider. One of the main differences between the two types of pipe is their manufacturing process. LSAW Steel Pipe is made by welding steel plates together, while Seamless Steel Pipe is made by piercing a solid steel billet. This difference in manufacturing process can affect the overall quality and performance of the pipe.

Another important factor to consider when comparing LSAW Steel Pipe and Seamless Steel Pipe is their cost. LSAW Steel Pipe is typically less expensive to manufacture than Seamless Steel Pipe, making it a more cost-effective option for companies with limited budgets. However, Seamless Steel Pipe is often considered to be more reliable and durable than LSAW Steel Pipe, making it a better long-term investment for companies that require a high level of performance and reliability.

In addition to cost and manufacturing process, companies should also consider the specific requirements of their application when choosing between LSAW Steel Pipe and Seamless Steel Pipe. LSAW Steel Pipe is well-suited for applications that require a high level of strength and durability, while Seamless Steel Pipe is ideal for applications that require a high level of precision and reliability. By carefully considering these factors, companies can choose the best type of pipe for their specific needs.

In conclusion, both LSAW Steel Pipe and Seamless Steel Pipe have their own unique characteristics and advantages. When comparing the two types of pipe in API 5L X42 Nace MR0175 ASTM36.19 ASTM252 Carbon Steel Line Pipe applications, companies should consider factors such as manufacturing process, cost, and specific application requirements in order to choose the best option for their needs. By carefully evaluating these factors, companies can ensure that they select the right type of pipe for their project, ultimately leading to a successful and efficient outcome.