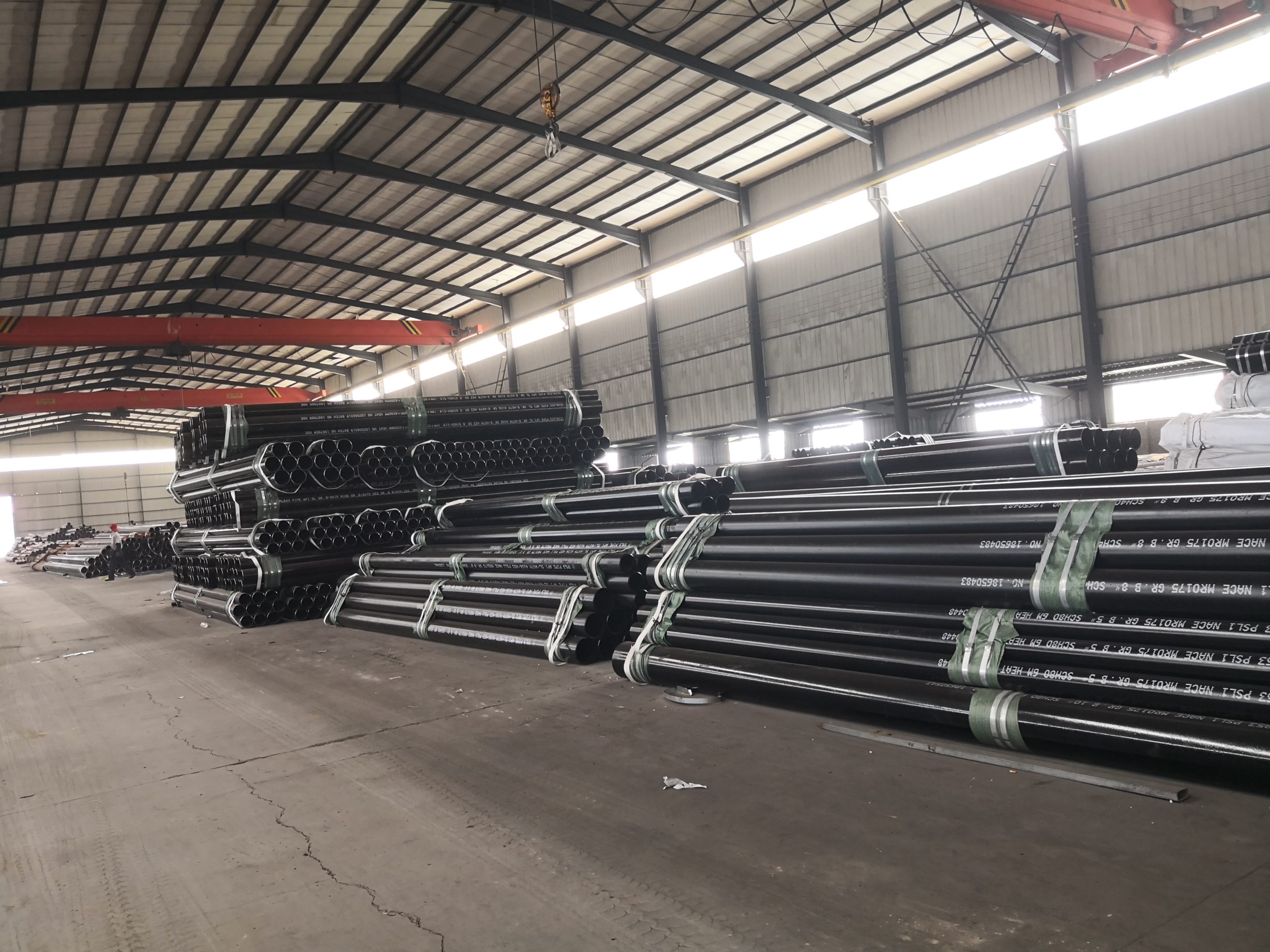

Advantages of Using ASTM A106 A53 API 5L Carbon Seamless steel Pipe in Industrial Applications

Carbon steel pipes are widely used in various industrial applications due to their durability, strength, and versatility. Among the different types of carbon steel pipes available in the market, ASTM A106, A53, and API 5L carbon seamless steel pipes are some of the most popular choices. These pipes are known for their high-quality construction and excellent performance in demanding environments.

One of the key advantages of using ASTM A106, A53, and API 5L carbon seamless steel pipes is their superior strength and durability. These pipes are made from high-quality carbon steel, which is known for its exceptional Tensile strength and resistance to corrosion. This makes them ideal for use in applications where high pressure, high temperature, or corrosive substances are present.

In addition to their strength and durability, ASTM A106, A53, and API 5L carbon seamless steel pipes are also known for their excellent weldability. This means that these pipes can be easily welded together to create a seamless and leak-proof connection. This is particularly important in industrial applications where the integrity of the piping system is crucial for the safety and efficiency of the operation.

Another advantage of using ASTM A106, A53, and API 5L carbon seamless steel pipes is their uniformity and consistency in terms of dimensions and properties. These pipes are manufactured according to strict industry standards, ensuring that each pipe meets the required specifications for Wall thickness, diameter, and Mechanical properties. This uniformity makes it easier to design and install piping systems, as there is no need to account for variations in pipe dimensions.

Furthermore, ASTM A106, A53, and API 5L carbon seamless steel pipes are available in a wide range of sizes and thicknesses to suit different industrial applications. Whether you need a small diameter pipe for a residential plumbing system or a large diameter pipe for a high-pressure industrial process, there is a suitable carbon seamless steel pipe available to meet your requirements.

In addition to their strength, durability, weldability, and uniformity, ASTM A106, A53, and API 5L carbon seamless steel pipes are also known for their excellent thermal conductivity. This means that these pipes can efficiently transfer heat from one location to another, making them ideal for use in applications where heat transfer is important, such as in heating and cooling systems.

Overall, ASTM A106, A53, and API 5L carbon seamless steel pipes offer a wide range of advantages for industrial applications. From their superior strength and durability to their excellent weldability, uniformity, and thermal conductivity, these pipes are a reliable and cost-effective choice for a variety of piping systems. Whether you are working in the Oil and gas industry, chemical processing, power generation, or any other industrial sector, ASTM A106, A53, and API 5L carbon seamless steel pipes are a versatile and dependable option for your piping needs.

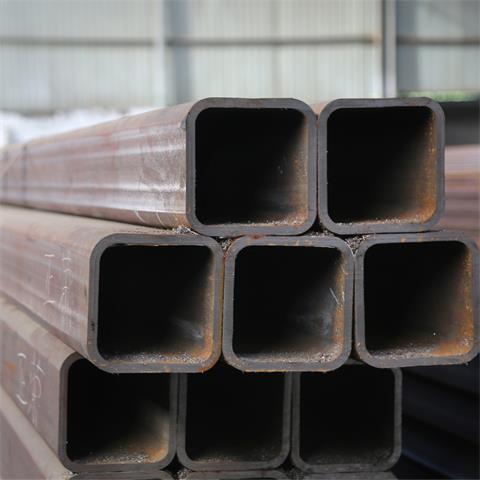

Key Differences Between Hot Rolled and Cold Rolled Carbon Steel Pipe for Various Construction Projects

When it comes to choosing the right carbon steel pipe for construction projects, there are two main options to consider: hot rolled and cold rolled. Both ASTM A106 and A53, as well as API 5L, are popular choices for seamless carbon steel pipes. Understanding the key differences between hot rolled and cold rolled carbon steel pipes can help you make an informed decision on which type is best suited for your specific project requirements.

Hot rolled carbon steel pipes are manufactured by passing a solid billet through a series of rollers at high temperatures. This process results in a seamless pipe with a rough surface finish. Hot rolled pipes are known for their strength and durability, making them ideal for applications that require high pressure and temperature resistance. These pipes are commonly used in industries such as oil and gas, petrochemical, and construction.

On the other hand, cold rolled carbon steel pipes are produced by cold drawing a solid billet through a series of dies at room temperature. This process results in a seamless pipe with a smooth surface finish. Cold rolled pipes are known for their precision and uniformity, making them ideal for applications that require tight tolerances and a polished appearance. These pipes are commonly used in industries such as automotive, aerospace, and manufacturing.

One of the key differences between hot rolled and cold rolled carbon steel pipes is their mechanical properties. Hot rolled pipes have a higher tensile strength and Yield strength compared to cold rolled pipes. This makes hot rolled pipes more suitable for applications that require heavy-duty performance and structural integrity. Cold rolled pipes, on the other hand, have a higher dimensional accuracy and surface finish compared to hot rolled pipes. This makes cold rolled pipes more suitable for applications that require precise measurements and a polished appearance.

Another key difference between hot rolled and cold rolled carbon steel pipes is their cost. Hot rolled pipes are generally more cost-effective than cold rolled pipes due to their simpler manufacturing process. However, cold rolled pipes offer higher quality and consistency, which may justify the higher cost for certain applications. It is important to consider your project requirements and budget constraints when choosing between hot rolled and cold rolled carbon steel pipes.

In conclusion, both hot rolled and cold rolled carbon steel pipes have their own unique advantages and disadvantages. Hot rolled pipes are known for their strength and durability, while cold rolled pipes are known for their precision and uniformity. Understanding the key differences between these two types of pipes can help you make an informed decision on which type is best suited for your specific project requirements. Whether you choose ASTM A106, A53, or API 5L, selecting the right carbon steel pipe is essential for the success of your construction project.