Advantages of Using ASTM AISI SS Seamless Pipe

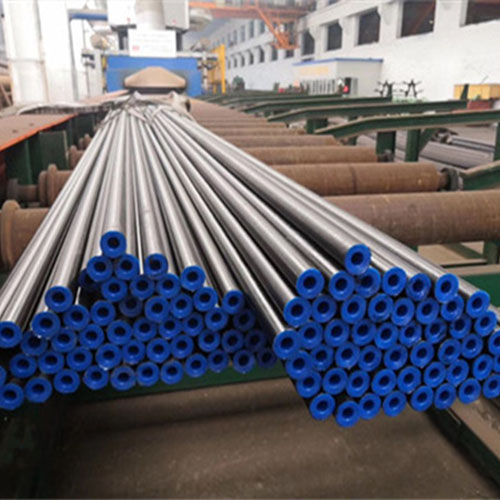

Stainless steel pipes are widely used in various industries due to their durability, Corrosion resistance, and high strength. Among the different types of stainless steel pipes available in the market, ASTM AISI SS seamless pipes are highly sought after for their superior quality and performance. These pipes are manufactured using advanced technology and adhere to strict quality standards set by the American Society for Testing and Materials (ASTM) and the American Iron and Steel Institute (AISI).

One of the key advantages of using ASTM AISI SS seamless pipes is their seamless construction, which eliminates the need for Welding and ensures a leak-proof and reliable connection. Seamless pipes are made by piercing a solid billet of stainless steel to create a hollow tube, which is then Cold drawn to achieve the desired dimensions and properties. This manufacturing process results in a pipe with a smooth and uniform surface finish, free from any weld seams or joints that could weaken the structure and compromise its integrity.

Another advantage of ASTM AISI SS seamless pipes is their high corrosion resistance, which is essential for applications where the pipe comes into contact with corrosive substances or environments. Stainless steel is inherently resistant to corrosion due to the presence of chromium, which forms a protective oxide layer on the surface of the pipe, preventing rust and corrosion from developing. This makes ASTM AISI SS seamless pipes ideal for use in industries such as chemical processing, Oil and gas, and food and beverage, where corrosion resistance is critical to the performance and longevity of the piping system.

In addition to their corrosion resistance, ASTM AISI SS seamless pipes also offer excellent strength and durability, making them suitable for high-pressure and high-temperature applications. Stainless steel has a high Tensile strength and can withstand extreme conditions without deforming or failing, ensuring the safety and reliability of the piping system. Seamless pipes are particularly well-suited for applications that require high levels of structural integrity, such as in power generation plants, petrochemical refineries, and offshore drilling platforms.

Furthermore, ASTM AISI SS seamless pipes are easy to install and maintain, thanks to their precise dimensions and smooth surface finish. The seamless construction of these pipes allows for a tight and secure fit, reducing the risk of leaks and ensuring efficient fluid flow. Additionally, stainless steel is easy to clean and sanitize, making it ideal for use in industries where hygiene is a priority, such as pharmaceutical manufacturing and food processing.

In conclusion, ASTM AISI SS seamless pipes offer a range of advantages that make them a preferred choice for various industrial applications. Their seamless construction, high corrosion resistance, excellent strength, and ease of installation and maintenance make them a reliable and cost-effective solution for piping systems that require durability and performance. Whether used in chemical processing, oil and gas, or food and beverage industries, ASTM AISI SS seamless pipes deliver superior quality and reliability that meet the stringent requirements of modern industrial applications.