Advantages of Using ASTM Inox Metal Tube for Various Applications

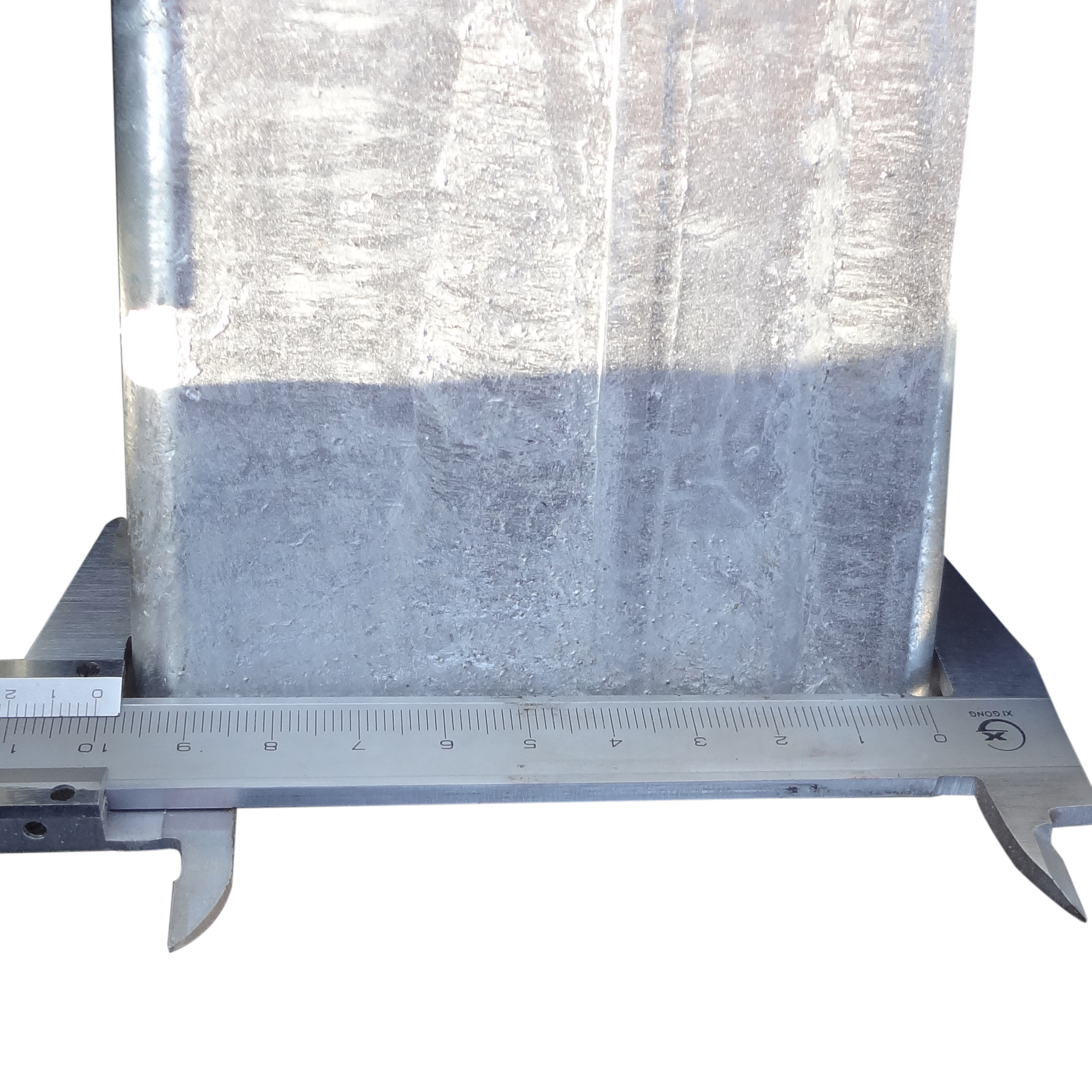

Stainless steel is a versatile Material that is widely used in various industries due to its durability, Corrosion resistance, and aesthetic appeal. ASTM Inox metal tubes, specifically round, square, and rectangular tubes made from stainless steel grades such as 201, 304, 316, 316L, 321, 309, 310, 410, 420, and 430, offer numerous advantages for a wide range of applications. One of the key advantages of using ASTM Inox metal tubes is their superior corrosion resistance. Stainless steel is inherently resistant to corrosion, making it ideal for applications where exposure to moisture, chemicals, or harsh environments is a concern. This corrosion resistance ensures that the metal tubes maintain their structural integrity and appearance over time, reducing the need for frequent maintenance or replacement. In addition to corrosion resistance, ASTM Inox metal tubes are also known for their high strength and durability. Stainless steel is a strong material that can withstand heavy loads and high temperatures, making it suitable for a variety of structural applications. Whether used in construction, automotive, or industrial settings, stainless steel tubes provide reliable support and longevity, ensuring the safety and stability of the structures they are incorporated into. Furthermore, ASTM Inox metal tubes are available in a wide range of sizes and shapes, including round, square, and rectangular profiles. This versatility allows for greater flexibility in design and construction, as the tubes can be easily customized to fit specific requirements. Whether used for architectural purposes, machinery components, or piping systems, stainless steel tubes can be tailored to meet the unique needs of each application.

Furthermore, ASTM Inox metal tubes are available in a wide range of sizes and shapes, including round, square, and rectangular profiles. This versatility allows for greater flexibility in design and construction, as the tubes can be easily customized to fit specific requirements. Whether used for architectural purposes, machinery components, or piping systems, stainless steel tubes can be tailored to meet the unique needs of each application.

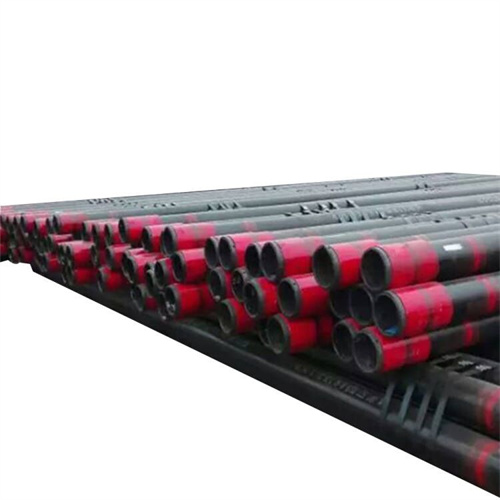

Comparison of Different Grades of Stainless Steel in Seamless and Welded Pipes

Stainless steel is a versatile and durable material that is commonly used in a wide range of industries, from construction to manufacturing. When it comes to Stainless steel pipes, there are several different grades available, each with its own unique properties and characteristics. In this article, we will compare the different grades of stainless steel in seamless and welded pipes, focusing on ASTM Inox Metal Tube Round Square Rectangular Ss 201, 304, 316, 316L, 321, 309, 310, 410, 420, and 430.| Labels | Outside diameter (d/mm) | T&C (kg/m) | Wall thickness (t/mm) | Type of end-finish | |||||||

| 1 | 2 | J55/ K55 | M65 | L80/ R95 | N80-1/Q | C90/ T95 | P110 | Q125 | |||

| 4-1/2 | 9.50 | 114.30 | 14.14 | 5.21 | PS | PS | – | – | – | – | – |

| 10.50 | 114.30 | 15.63 | 5.69 | PSB | PSB | – | – | – | – | – | |

| 11.60 | 114.30 | 17.26 | 6.35 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 13.50 | 114.30 | 20.09 | 7.37 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 15.10 | 114.30 | 22.47 | 8.56 | – | – | – | – | – | PLB | PLB | |

| 5 | 11.50 | 127.00 | 17.11 | 5.59 | PS | PS | – | – | – | – | – |

| 13.00 | 127.00 | 19.35 | 6.43 | PSLB | PSLB | – | – | – | – | – | |

| 15.00 | 127.00 | 22.32 | 7.52 | PSLB | PLB | SLB | PLB | PLB | PLB | ||

| 18.00 | 127.00 | 26.79 | 9.19 | – | PLB | SLB | PLB | PLB | PLB | PLB | |

| 21.40 | 127.00 | 31.85 | 11.10 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 23.20 | 127.00 | 34.53 | 12.14 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 24.10 | 127.00 | 35.87 | 12.70 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 5-1/2 | 14.00 | 139.70 | 20.83 | 6.20 | PS | PS | – | – | – | – | – |

| 15.50 | 139.70 | 23.07 | 6.98 | PSLB | PSLB | – | – | – | – | – | |

| 17.00 | 139.70 | 25.30 | 7.72 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 20.00 | 139.70 | 29.76 | 9.17 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 23.00 | 139.70 | 34.23 | 10.54 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 26.80 | 139.70 | 39.88 | 12.70 | – | – | – | – | P | – | – | |

| 29.70 | 139.70 | 44.20 | 14.27 | – | – | – | – | P | – | – | |

| 32.60 | 139.70 | 48.52 | 15.88 | – | – | – | – | P | – | – | |

| 35.30 | 139.70 | 52.53 | 17.45 | – | – | – | – | P | – | – | |

| 38.00 | 139.70 | 56.55 | 19.05 | – | – | – | – | P | – | – | |

| 40.50 | 139.70 | 60.27 | 20.62 | – | – | – | – | P | – | – | |

| 43.10 | 139.70 | 64.14 | 22.22 | – | – | – | – | P | – | – | |

| 6-5/8 | 20.00 | 168.28 | 29.76 | 7.32 | PSLB | PSLB | – | – | – | – | – |

| 24.00 | 168.28 | 35.72 | 8.94 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 28.00 | 168.28 | 41.67 | 10.59 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 32.00 | 168.28 | 47.62 | 12.06 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 7 | 17.00 | 177.80 | 25.30 | 5.87 | – | – | – | – | – | – | – |

| 20.00 | 177.80 | 29.76 | 6.91 | PS | PS | – | – | – | – | – | |

| 23.00 | 177.80 | 34.23 | 8.05 | PSLB | PLB | PLB | PLB | PLB | – | – | |

| 26.00 | 177.80 | 38.69 | 9.19 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 29.00 | 177.80 | 43.16 | 10.36 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 32.00 | 177.80 | 47.62 | 11.51 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 35.00 | 177.80 | 52.09 | 12.65 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 38.00 | 177.80 | 56.55 | 13.72 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 42.70 | 177.80 | 63.55 | 15.88 | – | – | – | – | P | – | – | |

| 46.40 | 177.80 | 69.05 | 17.45 | – | – | – | – | P | – | – | |

| 50.10 | 177.80 | 74.56 | 19.05 | – | – | – | – | P | – | – | |

| 53.60 | 177.80 | 79.77 | 20.62 | – | – | – | – | P | – | – | |

| 57.10 | 177.80 | 84.98 | 22.22 | – | – | – | – | P | – | – | |

| 7-5/8 | 24.00 | 193.68 | 35.72 | 7.62 | – | – | – | – | – | – | |

| 26.40 | 193.68 | 39.29 | 8.33 | PSLB | PSLB | PLB | PLB | PLB | – | – | |

| 29.70 | 193.68 | 44.20 | 9.52 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 33.70 | 193.68 | 50.15 | 10.92 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 39.00 | 193.68 | 58.04 | 12.70 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 42.80 | 193.68 | 63.69 | 14.27 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 45.30 | 193.68 | 67.42 | 15.11 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 47.10 | 193.68 | 70.09 | 15.88 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 51.20 | 193.68 | 76.20 | 17.45 | – | – | – | – | P | – | – | |

| 55.30 | 193.68 | 82.30 | 19.05 | – | – | – | – | P | – | – | |

| 7-3/4 | 46.10 | 196.85 | 68.61 | 15.11 | – | – | P | P | P | P | P |

| 8-5/8 | 24.00 | 219.08 | 35.72 | 6.71 | PS | PS | – | – | – | – | – |

| 28.00 | 219.08 | 41.67 | 7.72 | PS | – | – | – | – | – | ||

| 32.00 | 219.08 | 47.62 | 8.94 | PSLB | PSLB | – | – | – | – | – | |

| 36.00 | 219.08 | 53.58 | 10.16 | PSLB | PSLB | PLB | PLB | PLB | PLB | – | |

| 40.00 | 219.08 | 59.53 | 11.43 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 44.00 | 219.08 | 65.48 | 12.70 | – | – | PLB | PLB | PLB | PLB | – | |

| 49.00 | 219.08 | 72.92 | 14.15 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 9-5/8 | 32.30 | 244.48 | 48.07 | 7.92 | – | – | – | – | – | – | – |

| 36.00 | 244.48 | 53.58 | 8.94 | PSLB | PSLB | – | – | – | – | – | |

| 40.00 | 244.48 | 59.53 | 10.03 | PSLB | PSLB | PLB | PLB | PLB | – | – | |

| 43.50 | 244.48 | 64.74 | 11.05 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 47.00 | 244.48 | 69.95 | 11.99 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 53.50 | 244.48 | 79.62 | 13.84 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 58.40 | 244.48 | 86.91 | 15.11 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 59.40 | 244.48 | 88.40 | 15.47 | – | – | – | – | P | – | – | |

| 64.90 | 244.48 | 96.58 | 17.07 | – | – | – | – | P | – | – | |

| 70.30 | 244.48 | 104.62 | 18.64 | – | – | – | – | P | – | – | |

| 75.60 | 244.48 | 112.51 | 20.24 | – | – | – | – | P | – | – | |

| 10-3/4 | 32.75 | 273.05 | 48.74 | 7.09 | – | – | – | – | – | – | – |

| 40.50 | 273.05 | 60.27 | 8.89 | PSB | PSB | – | – | – | – | – | |

| 45.50 | 273.05 | 67.71 | 10.16 | PSB | PSB | – | – | – | – | – | |

| 51.00 | 273.05 | 75.90 | 11.43 | PSB | PSB | PSB | PSB | PSB | PSB | – | |

| 55.50 | 273.05 | 82.60 | 12.57 | – | PSB | PSB | PSB | PSB | PSB | – | |

| 60.70 | 273.05 | 90.33 | 13.84 | – | – | – | – | PSB | PSB | PSB | |

| 65.70 | 273.05 | 97.77 | 15.11 | – | – | – | – | PSB | PSB | PSB | |

| 73.20 | 273.05 | 108.94 | 17.07 | – | – | – | – | P | – | – | |

| 79.20 | 273.05 | 117.87 | 18.64 | – | – | – | – | P | – | – | |

| 85.30 | 273.05 | 126.94 | 20.24 | – | – | – | – | P | – | – | |

| 11-3/4 | 42.00 | 298.45 | 62.50 | 8.46 | – | – | – | – | – | – | – |

| 47.00 | 298.45 | 69.95 | 9.53 | PSB | PSB | – | – | – | – | – | |

| 54.00 | 298.45 | 80.36 | 11.05 | PSB | PSB | – | – | – | – | – | |

| 60.00 | 298.45 | 89.29 | 12.42 | PSB | PSB | PSB | PSB | PSB | PSB | PSB | |

| 65.00 | 298.45 | 96.73 | 13.56 | – | – | P | P | P | P | P | |

| 71.00 | 298.45 | 105.66 | 14.78 | – | – | P | P | P | P | P | |

| 13-3/8 | 48.00 | 339.72 | 71.43 | 8.38 | – | – | – | – | – | – | – |

| 54.50 | 339.72 | 81.11 | 9.65 | PSB | PSB | – | – | – | – | – | |

| 61.00 | 339.72 | 90.78 | 10.92 | PSB | PSB | – | – | – | – | – | |

| 68.00 | 339.72 | 101.20 | 12.19 | PSB | PSB | PSB | PSB | PSB | PSB | – | |

| 72.00 | 339.72 | 107.15 | 13.06 | – | – | PSB | PSB | PSB | PSB | PSB | |

| 16 | 65.00 | 406.40 | 96.73 | 9.53 | – | – | – | – | – | – | – |

| 75.00 | 406.40 | 111.62 | 11.13 | PSB | PSB | – | – | – | – | – | |

| 84.00 | 406.40 | 125.01 | 12.57 | PSB | PSB | – | – | – | – | – | |

| 109.00 | 406.40 | 162.21 | 16.66 | P | – | P | P | – | P | P | |

| 18-5/8 | 87.50 | 473.08 | 130.22 | 11.05 | PSB | PSB | – | – | – | – | – |

| 20 | 94.00 | 508.00 | 139.89 | 11.13 | PSLB | PSLB | – | – | – | – | – |

| 106.50 | 508.00 | 158.49 | 12.70 | PSLB | PSLB | – | – | – | – | – | |

| 133.00 | 508.00 | 197.93 | 16.13 | PSLB | – | – | – | – | – | – | |

410 stainless steel is a martensitic grade known for its high strength and Hardness. 410 stainless steel pipes are commonly used in the automotive industry for exhaust systems and in the construction industry for structural support.

420 stainless steel is a martensitic grade that offers good corrosion resistance and high hardness. 420 stainless steel pipes are often used in the medical industry for surgical instruments and in the food processing industry for cutting tools.

410 stainless steel is a martensitic grade known for its high strength and Hardness. 410 stainless steel pipes are commonly used in the automotive industry for exhaust systems and in the construction industry for structural support.

420 stainless steel is a martensitic grade that offers good corrosion resistance and high hardness. 420 stainless steel pipes are often used in the medical industry for surgical instruments and in the food processing industry for cutting tools.

| OD (mm) | Wall Thickness (mm) | |||||||||||||

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5-7 | 7.5-8 | 8.5-9 | 9.5-10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ133 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ140 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ146 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ152 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ159 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ168 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||