Advantages of Using Seamless steel Pipes in Industrial Applications

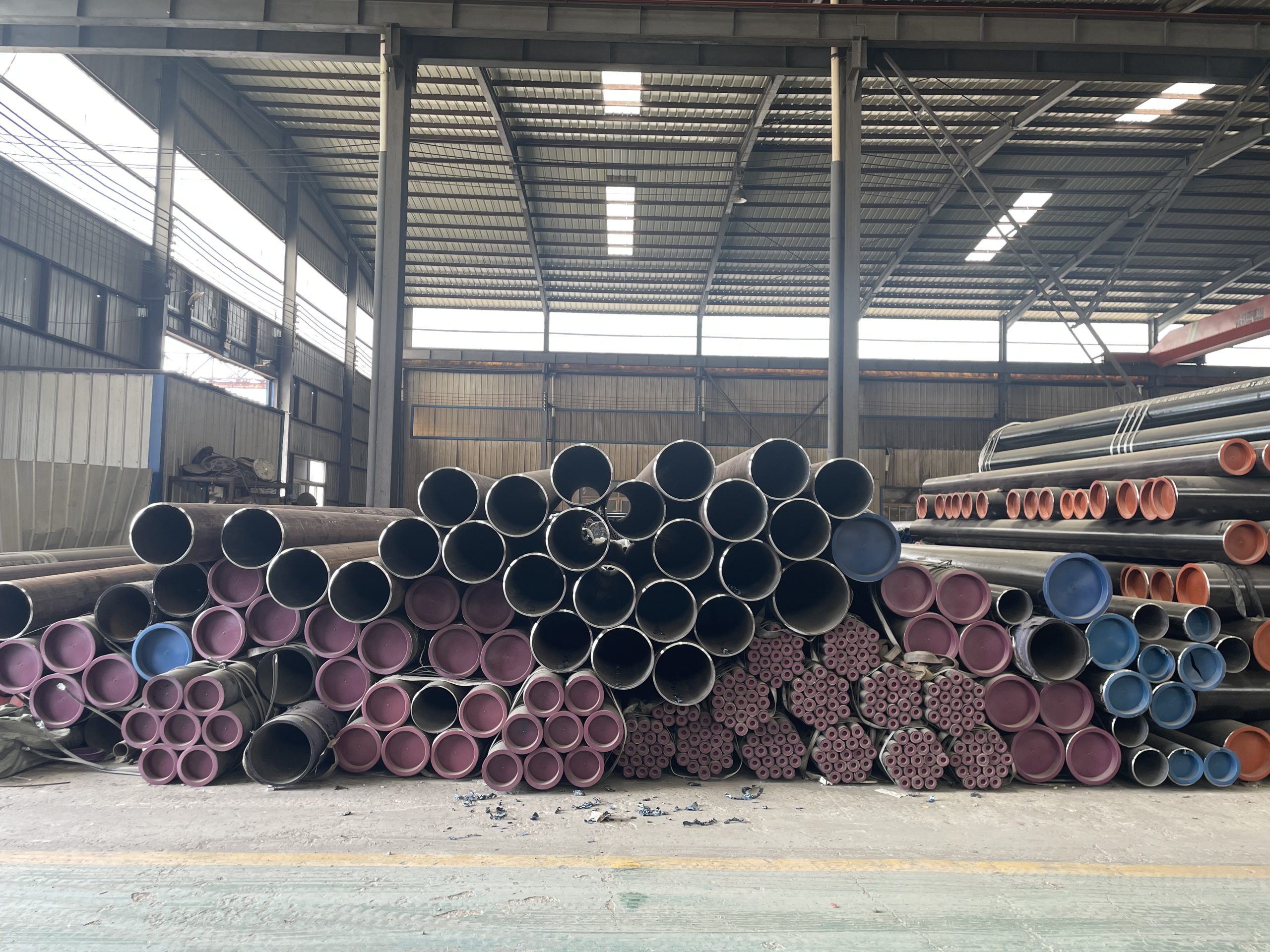

Seamless steel pipes have long been a cornerstone in various industrial applications, offering a myriad of advantages over their welded counterparts. Among the plethora of options available in the market, the batch of seamless steel pipes in Ø 355.6 x 15.9 mm from zssteeltube stands out for its superior quality and reliability.

One of the primary advantages of seamless steel pipes lies in their enhanced strength and durability. Unlike welded pipes, seamless pipes are formed from a single piece of steel, eliminating the weak points that can arise from weld seams. This inherent strength makes seamless pipes ideal for applications requiring high pressure or extreme temperatures, such as in the Oil and gas industry or power generation plants.

Furthermore, the absence of weld seams in seamless pipes also contributes to improved Corrosion resistance. Welded pipes are susceptible to corrosion at the weld seam due to the introduction of impurities and inconsistencies during the Welding process. In contrast, seamless pipes exhibit uniform composition throughout, reducing the risk of corrosion and extending the lifespan of the piping system.

Another notable advantage of seamless steel pipes is their smooth internal surface finish. The seamless manufacturing process results in pipes with a consistent diameter and smooth bore, minimizing friction and turbulence during fluid flow. This characteristic is particularly advantageous in applications where fluid purity or flow efficiency is paramount, such as in pharmaceutical manufacturing or food processing facilities.

Additionally, seamless steel pipes offer greater dimensional accuracy and tolerances compared to welded pipes. The seamless manufacturing process allows for tighter control over Wall thickness and diameter, ensuring precise specifications are met. This level of precision is essential in industries where deviations from specified dimensions can compromise the integrity of the system, such as in structural engineering or automotive manufacturing.

Moreover, seamless steel pipes are inherently more flexible and adaptable to various installation requirements. Their uniformity and consistency make them easier to cut, shape, and weld compared to welded pipes, allowing for seamless integration into complex piping systems or custom configurations. This versatility makes seamless pipes the preferred choice for architects, engineers, and contractors seeking reliable and efficient solutions for their projects.

In terms of performance, seamless steel pipes also exhibit superior Mechanical properties compared to welded pipes. The homogeneous structure of seamless pipes results in higher Tensile strength, impact resistance, and fatigue endurance, making them well-suited for demanding applications subjected to heavy loads or dynamic stress conditions.

Furthermore, seamless steel pipes offer cost savings over the long term due to their lower maintenance requirements and longer service life. The durability and reliability of seamless pipes reduce the need for frequent inspections, repairs, and replacements, translating into reduced downtime and operational expenses for industrial facilities.

In conclusion, the batch of seamless steel pipes in Ø 355.6 x 15.9 mm from zssteeltube represents a superior choice for industrial applications requiring strength, durability, corrosion resistance, and dimensional accuracy. With their seamless construction, smooth internal surface finish, and superior mechanical properties, seamless pipes offer unmatched performance and reliability across a wide range of industries. Whether in oil and gas exploration, chemical processing, power generation, or infrastructure development, seamless steel pipes continue to play a vital role in shaping the future of industrial engineering.

Understanding the Specifications and Applications of Ø 355.6 x 15.9 mm Seamless Steel Pipes

When it comes to industrial applications that require robust and reliable materials, seamless steel pipes often stand out as a top choice. Among the myriad of specifications available, one particular batch of seamless steel pipes, with dimensions of Ø 355.6 x 15.9 mm, merits attention. Manufactured by zssteeltube, these pipes offer a combination of size, durability, and versatility that makes them suitable for various industries and applications.

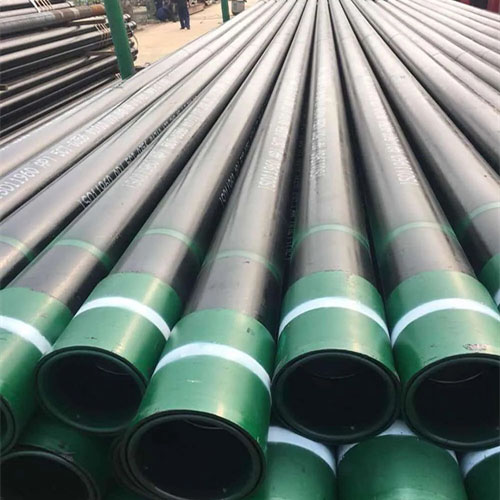

4 inch od pipeMeasuring 355.6 millimeters in outer diameter and 15.9 millimeters in thickness, these seamless steel pipes boast a robust build capable of withstanding high pressure and heavy loads. The seamless construction eliminates the risk of weak points and ensures uniformity throughout the Length of the Pipe. This characteristic is crucial in applications where structural integrity is paramount, such as in oil and gas pipelines, industrial machinery, and construction projects.

One of the key advantages of seamless steel pipes lies in their ability to withstand extreme conditions. Whether subjected to high temperatures, corrosive environments, or intense pressure, these pipes maintain their integrity, ensuring uninterrupted operation and longevity. This resilience makes them indispensable in industries where failure is not an option, such as petrochemical plants, power generation facilities, and offshore drilling platforms.

Moreover, the Ø 355.6 x 15.9 mm dimensions of these pipes offer a balance between size and strength, making them versatile for a wide range of applications. From transporting fluids and gases to serving as structural components in buildings and bridges, these pipes fulfill diverse roles across industries. Their uniform dimensions also facilitate seamless integration into existing systems, minimizing downtime and installation costs.

In the oil and gas sector, Ø 355.6 x 15.9 mm seamless steel pipes play a crucial role in the extraction, transportation, and refining of petroleum products. Whether used in drilling operations or in the construction of pipelines and refineries, these pipes ensure the efficient flow of crude oil and natural gas while withstanding the harsh conditions of exploration and production environments.

Similarly, in the construction industry, these seamless steel pipes find application in structural frameworks, providing support and stability to buildings, bridges, and infrastructure projects. Their durability and resistance to corrosion make them ideal for outdoor installations where exposure to the elements is inevitable. Additionally, their uniform dimensions simplify construction processes, enabling faster and more efficient assembly.

Beyond traditional industries, Ø 355.6 x 15.9 mm seamless steel pipes also find niche applications in sectors such as automotive manufacturing, aerospace engineering, and renewable energy. In automotive production, they are used in exhaust systems and chassis components, where strength and reliability are essential. In aerospace applications, their lightweight yet sturdy construction makes them suitable for aircraft frames and propulsion systems. Furthermore, in renewable energy projects such as wind farms and solar installations, these pipes support the infrastructure necessary for harnessing clean energy sources.

In conclusion, the batch of seamless steel pipes with dimensions of Ø 355.6 x 15.9 mm offered by zssteeltube represents a versatile and dependable solution for various industrial applications. With their robust construction, resistance to extreme conditions, and diverse range of uses, these pipes continue to be integral to the functioning of numerous industries worldwide. Whether in oil and gas, construction, automotive, or beyond, their reliability and performance make them a preferred choice for engineers and manufacturers alike.