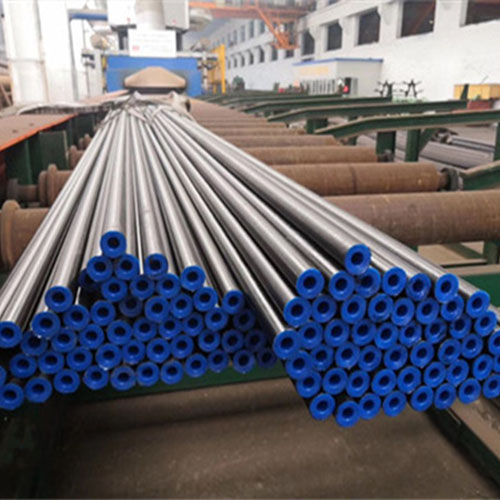

Benefits of Using Chinese Factory Supply Stainless steel Seamless Pipe

Stainless steel seamless pipes are a popular choice in various industries due to their durability, Corrosion resistance, and high strength. Chinese factories are known for producing high-quality stainless steel seamless pipes, including grades like 304, 304L, 316, 316L, 321, and 904L. These pipes are widely used in industries such as Oil and gas, chemical processing, food and beverage, and pharmaceuticals.| Applications: | For tubular heat exchangers,condensers,and similar heat transfer apparatuses. |

| Size (mm): | O.D.: 6.0~168.0; W.T.: 1~15; L: max 12000 |

Comparison of Different Grades (304, 304L, 316, 316L, 321, 904L) in Stainless Steel Seamless Tube Manufacturing

Stainless steel seamless tubes are widely used in various industries due to their excellent corrosion resistance, high strength, and durability. When it comes to choosing the right grade of stainless steel for seamless tube manufacturing, there are several options available, including 304, 304L, 316, 316L, 321, and 904L. Each grade has its own unique properties and characteristics that make it suitable for specific applications. One of the most commonly used grades of stainless steel for seamless tube manufacturing is 304. This grade is known for its excellent corrosion resistance, good weldability, and high strength. It is often used in applications where corrosion resistance is a primary concern, such as in the food and beverage industry, chemical processing, and medical equipment.

One of the most commonly used grades of stainless steel for seamless tube manufacturing is 304. This grade is known for its excellent corrosion resistance, good weldability, and high strength. It is often used in applications where corrosion resistance is a primary concern, such as in the food and beverage industry, chemical processing, and medical equipment.

| Labels | Outside diameter (d/mm) | T&C (kg/m) | Wall thickness (t/mm) | Type of end-finish | |||||||

| 1 | 2 | J55/ K55 | M65 | L80/ R95 | N80-1/Q | C90/ T95 | P110 | Q125 | |||

| 4-1/2 | 9.50 | 114.30 | 14.14 | 5.21 | PS | PS | – | – | – | – | – |

| 10.50 | 114.30 | 15.63 | 5.69 | PSB | PSB | – | – | – | – | – | |

| 11.60 | 114.30 | 17.26 | 6.35 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 13.50 | 114.30 | 20.09 | 7.37 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 15.10 | 114.30 | 22.47 | 8.56 | – | – | – | – | – | PLB | PLB | |

| 5 | 11.50 | 127.00 | 17.11 | 5.59 | PS | PS | – | – | – | – | – |

| 13.00 | 127.00 | 19.35 | 6.43 | PSLB | PSLB | – | – | – | – | – | |

| 15.00 | 127.00 | 22.32 | 7.52 | PSLB | PLB | SLB | PLB | PLB | PLB | ||

| 18.00 | 127.00 | 26.79 | 9.19 | – | PLB | SLB | PLB | PLB | PLB | PLB | |

| 21.40 | 127.00 | 31.85 | 11.10 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 23.20 | 127.00 | 34.53 | 12.14 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 24.10 | 127.00 | 35.87 | 12.70 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 5-1/2 | 14.00 | 139.70 | 20.83 | 6.20 | PS | PS | – | – | – | – | – |

| 15.50 | 139.70 | 23.07 | 6.98 | PSLB | PSLB | – | – | – | – | – | |

| 17.00 | 139.70 | 25.30 | 7.72 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 20.00 | 139.70 | 29.76 | 9.17 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 23.00 | 139.70 | 34.23 | 10.54 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 26.80 | 139.70 | 39.88 | 12.70 | – | – | – | – | P | – | – | |

| 29.70 | 139.70 | 44.20 | 14.27 | – | – | – | – | P | – | – | |

| 32.60 | 139.70 | 48.52 | 15.88 | – | – | – | – | P | – | – | |

| 35.30 | 139.70 | 52.53 | 17.45 | – | – | – | – | P | – | – | |

| 38.00 | 139.70 | 56.55 | 19.05 | – | – | – | – | P | – | – | |

| 40.50 | 139.70 | 60.27 | 20.62 | – | – | – | – | P | – | – | |

| 43.10 | 139.70 | 64.14 | 22.22 | – | – | – | – | P | – | – | |

| 6-5/8 | 20.00 | 168.28 | 29.76 | 7.32 | PSLB | PSLB | – | – | – | – | – |

| 24.00 | 168.28 | 35.72 | 8.94 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 28.00 | 168.28 | 41.67 | 10.59 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 32.00 | 168.28 | 47.62 | 12.06 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 7 | 17.00 | 177.80 | 25.30 | 5.87 | – | – | – | – | – | – | – |

| 20.00 | 177.80 | 29.76 | 6.91 | PS | PS | – | – | – | – | – | |

| 23.00 | 177.80 | 34.23 | 8.05 | PSLB | PLB | PLB | PLB | PLB | – | – | |

| 26.00 | 177.80 | 38.69 | 9.19 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 29.00 | 177.80 | 43.16 | 10.36 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 32.00 | 177.80 | 47.62 | 11.51 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 35.00 | 177.80 | 52.09 | 12.65 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 38.00 | 177.80 | 56.55 | 13.72 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 42.70 | 177.80 | 63.55 | 15.88 | – | – | – | – | P | – | – | |

| 46.40 | 177.80 | 69.05 | 17.45 | – | – | – | – | P | – | – | |

| 50.10 | 177.80 | 74.56 | 19.05 | – | – | – | – | P | – | – | |

| 53.60 | 177.80 | 79.77 | 20.62 | – | – | – | – | P | – | – | |

| 57.10 | 177.80 | 84.98 | 22.22 | – | – | – | – | P | – | – | |

| 7-5/8 | 24.00 | 193.68 | 35.72 | 7.62 | – | – | – | – | – | – | |

| 26.40 | 193.68 | 39.29 | 8.33 | PSLB | PSLB | PLB | PLB | PLB | – | – | |

| 29.70 | 193.68 | 44.20 | 9.52 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 33.70 | 193.68 | 50.15 | 10.92 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 39.00 | 193.68 | 58.04 | 12.70 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 42.80 | 193.68 | 63.69 | 14.27 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 45.30 | 193.68 | 67.42 | 15.11 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 47.10 | 193.68 | 70.09 | 15.88 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 51.20 | 193.68 | 76.20 | 17.45 | – | – | – | – | P | – | – | |

| 55.30 | 193.68 | 82.30 | 19.05 | – | – | – | – | P | – | – | |

| 7-3/4 | 46.10 | 196.85 | 68.61 | 15.11 | – | – | P | P | P | P | P |

| 8-5/8 | 24.00 | 219.08 | 35.72 | 6.71 | PS | PS | – | – | – | – | – |

| 28.00 | 219.08 | 41.67 | 7.72 | PS | – | – | – | – | – | ||

| 32.00 | 219.08 | 47.62 | 8.94 | PSLB | PSLB | – | – | – | – | – | |

| 36.00 | 219.08 | 53.58 | 10.16 | PSLB | PSLB | PLB | PLB | PLB | PLB | – | |

| 40.00 | 219.08 | 59.53 | 11.43 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 44.00 | 219.08 | 65.48 | 12.70 | – | – | PLB | PLB | PLB | PLB | – | |

| 49.00 | 219.08 | 72.92 | 14.15 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 9-5/8 | 32.30 | 244.48 | 48.07 | 7.92 | – | – | – | – | – | – | – |

| 36.00 | 244.48 | 53.58 | 8.94 | PSLB | PSLB | – | – | – | – | – | |

| 40.00 | 244.48 | 59.53 | 10.03 | PSLB | PSLB | PLB | PLB | PLB | – | – | |

| 43.50 | 244.48 | 64.74 | 11.05 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 47.00 | 244.48 | 69.95 | 11.99 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 53.50 | 244.48 | 79.62 | 13.84 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 58.40 | 244.48 | 86.91 | 15.11 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 59.40 | 244.48 | 88.40 | 15.47 | – | – | – | – | P | – | – | |

| 64.90 | 244.48 | 96.58 | 17.07 | – | – | – | – | P | – | – | |

| 70.30 | 244.48 | 104.62 | 18.64 | – | – | – | – | P | – | – | |

| 75.60 | 244.48 | 112.51 | 20.24 | – | – | – | – | P | – | – | |

| 10-3/4 | 32.75 | 273.05 | 48.74 | 7.09 | – | – | – | – | – | – | – |

| 40.50 | 273.05 | 60.27 | 8.89 | PSB | PSB | – | – | – | – | – | |

| 45.50 | 273.05 | 67.71 | 10.16 | PSB | PSB | – | – | – | – | – | |

| 51.00 | 273.05 | 75.90 | 11.43 | PSB | PSB | PSB | PSB | PSB | PSB | – | |

| 55.50 | 273.05 | 82.60 | 12.57 | – | PSB | PSB | PSB | PSB | PSB | – | |

| 60.70 | 273.05 | 90.33 | 13.84 | – | – | – | – | PSB | PSB | PSB | |

| 65.70 | 273.05 | 97.77 | 15.11 | – | – | – | – | PSB | PSB | PSB | |

| 73.20 | 273.05 | 108.94 | 17.07 | – | – | – | – | P | – | – | |

| 79.20 | 273.05 | 117.87 | 18.64 | – | – | – | – | P | – | – | |

| 85.30 | 273.05 | 126.94 | 20.24 | – | – | – | – | P | – | – | |

| 11-3/4 | 42.00 | 298.45 | 62.50 | 8.46 | – | – | – | – | – | – | – |

| 47.00 | 298.45 | 69.95 | 9.53 | PSB | PSB | – | – | – | – | – | |

| 54.00 | 298.45 | 80.36 | 11.05 | PSB | PSB | – | – | – | – | – | |

| 60.00 | 298.45 | 89.29 | 12.42 | PSB | PSB | PSB | PSB | PSB | PSB | PSB | |

| 65.00 | 298.45 | 96.73 | 13.56 | – | – | P | P | P | P | P | |

| 71.00 | 298.45 | 105.66 | 14.78 | – | – | P | P | P | P | P | |

| 13-3/8 | 48.00 | 339.72 | 71.43 | 8.38 | – | – | – | – | – | – | – |

| 54.50 | 339.72 | 81.11 | 9.65 | PSB | PSB | – | – | – | – | – | |

| 61.00 | 339.72 | 90.78 | 10.92 | PSB | PSB | – | – | – | – | – | |

| 68.00 | 339.72 | 101.20 | 12.19 | PSB | PSB | PSB | PSB | PSB | PSB | – | |

| 72.00 | 339.72 | 107.15 | 13.06 | – | – | PSB | PSB | PSB | PSB | PSB | |

| 16 | 65.00 | 406.40 | 96.73 | 9.53 | – | – | – | – | – | – | – |

| 75.00 | 406.40 | 111.62 | 11.13 | PSB | PSB | – | – | – | – | – | |

| 84.00 | 406.40 | 125.01 | 12.57 | PSB | PSB | – | – | – | – | – | |

| 109.00 | 406.40 | 162.21 | 16.66 | P | – | P | P | – | P | P | |

| 18-5/8 | 87.50 | 473.08 | 130.22 | 11.05 | PSB | PSB | – | – | – | – | – |

| 20 | 94.00 | 508.00 | 139.89 | 11.13 | PSLB | PSLB | – | – | – | – | – |

| 106.50 | 508.00 | 158.49 | 12.70 | PSLB | PSLB | – | – | – | – | – | |

| 133.00 | 508.00 | 197.93 | 16.13 | PSLB | – | – | – | – | – | – | |

In conclusion, stainless steel seamless tubes are an essential component in various industries, and choosing the right grade of stainless steel is crucial for ensuring the success of a project. By understanding the properties and characteristics of different grades, manufacturers can select the most suitable grade for their specific application. Whether it is 304, 304L, 316, 316L, 321, or 904L stainless steel, each grade offers unique benefits that make it suitable for a wide range of applications.

In conclusion, stainless steel seamless tubes are an essential component in various industries, and choosing the right grade of stainless steel is crucial for ensuring the success of a project. By understanding the properties and characteristics of different grades, manufacturers can select the most suitable grade for their specific application. Whether it is 304, 304L, 316, 316L, 321, or 904L stainless steel, each grade offers unique benefits that make it suitable for a wide range of applications.