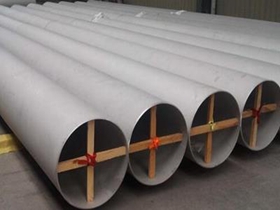

Oil casing is a steel Pipe used to support the wall of oil and gas wells to ensure the normal operation of the entire oil well during the drilling process and after completion. Each well requires several layers of casing depending on different drilling depths and geological conditions. After the casing is run down, cement cementing is required. It is different from the Tubing and drill pipe and cannot be reused. Therefore, the consumption of casing accounts for more than 70% of all oil well pipes.

The casing can be divided into: conduit, surface casing, technical casing and oil casing.

Steel grade of oil casing: H40, J55, K55, N80, L80, C90, T95, P110, Q125, V150, etc. Form of casing end processing: short round thread, long round thread, partial trapezoidal thread, special buckle, etc. Used for oil well drilling is mainly used to support the well wall during drilling and after completion, to ensure the drilling process and the normal operation of the entire oil well after completion.