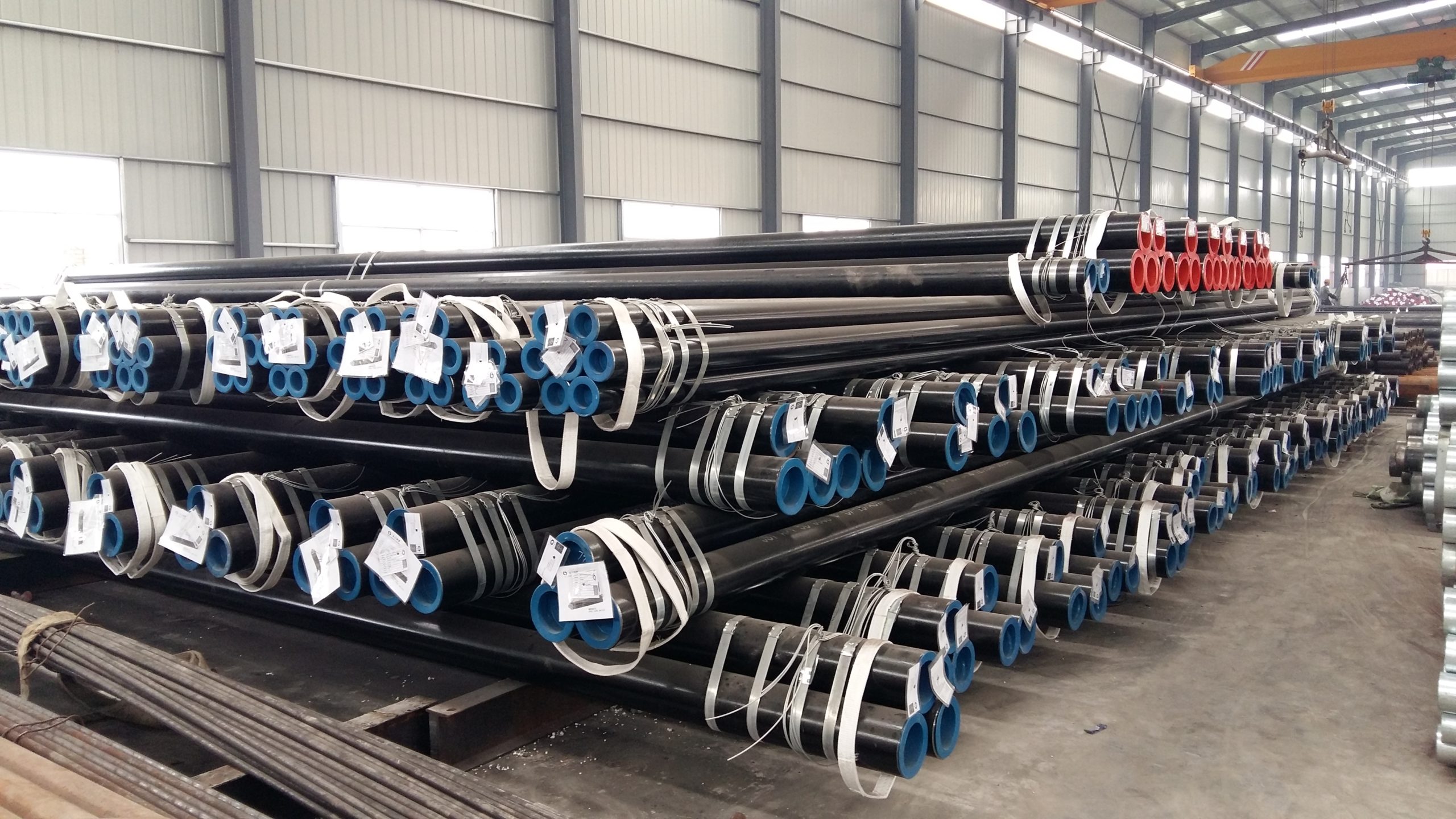

Exploring the Benefits of Common Connection Methods for Carbon steel Pipes

Person 1: “What are the benefits of using common connection methods for carbon steel pipes?”

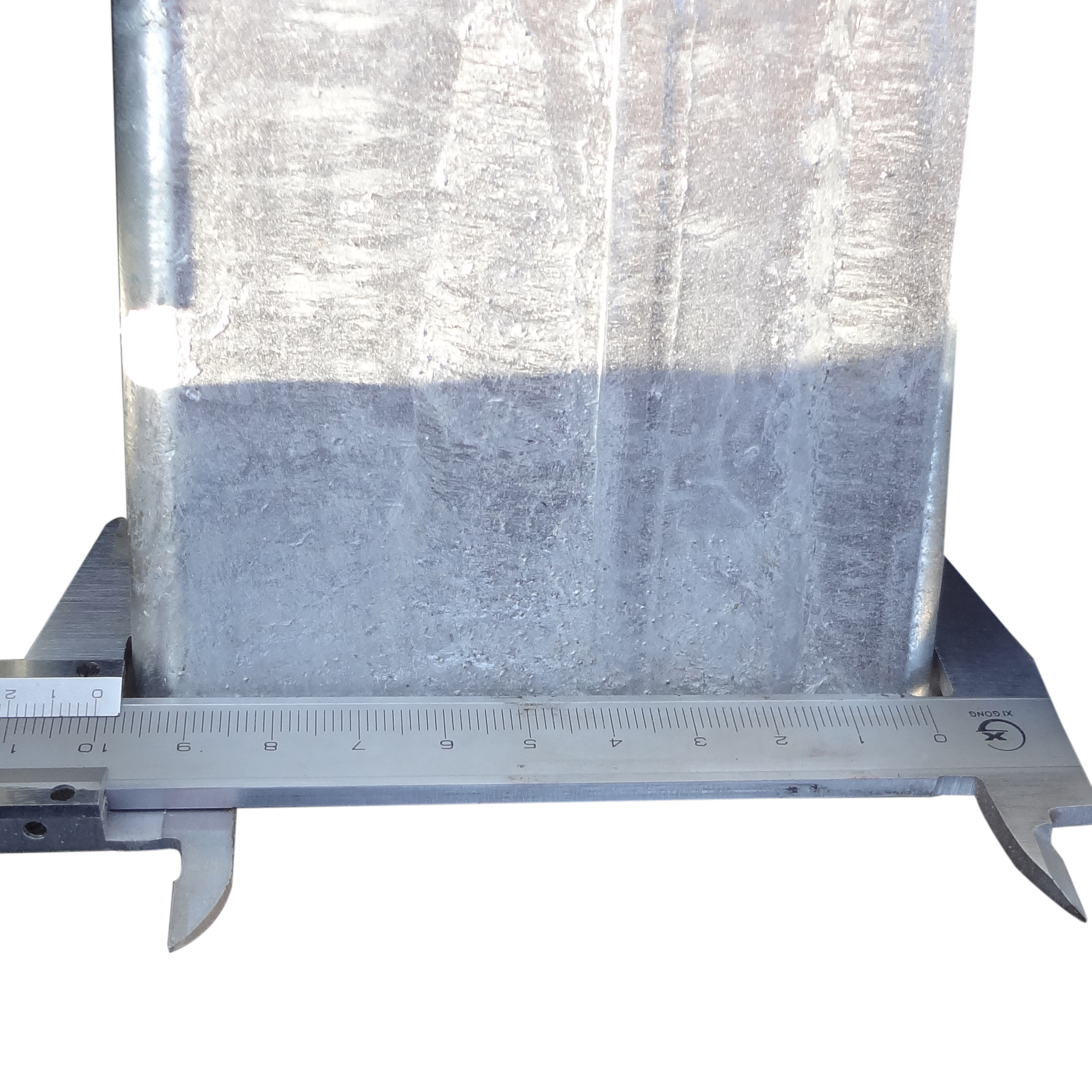

| Chemical Composition | C | Mn | P≤ | S≤ | Si≤ |

| 0.06-0.18 | 0.27-0.63 | 0.035 | 0.035 | 0.25 |

Person 2: “Well, there are several advantages to using common connection methods for carbon steel pipes. First, they are cost-effective. Common connection methods are typically less expensive than other methods, making them a great option for those on a budget. Additionally, they are easy to install and maintain, making them a great choice for DIY projects. Finally, they are reliable and durable, so you can be sure that your pipes will last for years to come.”

Understanding the Different Types of Carbon Steel Pipe Connections and Their Uses

Person 1: Hey, I’m looking for some information on carbon steel pipe connections.

Person 2: Sure, what do you need to know?

Person 1: Well, I’m trying to understand the different types of connections and their uses.

Person 2: Okay, let’s start with the most common type of connection, which is the butt weld. This type of connection is used to join two pieces of pipe together by Welding them along their Length. It’s a strong and reliable connection that is often used in high-pressure applications.

Person 1: What about socket welds?

Person 2: Socket welds are similar to butt welds, but they are used to join two pieces of pipe together at a 90-degree angle. This type of connection is often used in low-pressure applications.

Person 1: What about threaded connections?

Person 2: Threaded connections are used to join two pieces of pipe together by screwing them together. This type of connection is often used in low-pressure applications, but it can also be used in high-pressure applications if the pipe is reinforced with a sealant.