Exploring the Benefits of ERW Standard Pipe and ERW Line Pipe for Industrial Applications

ERW (Electric Resistance Welded) standard pipe and ERW line pipe are two of the most popular types of industrial piping available today. Both offer a variety of benefits that make them ideal for a wide range of applications. In this article, we will explore the advantages of ERW standard pipe and ERW line pipe and discuss how they can be used in industrial settings.

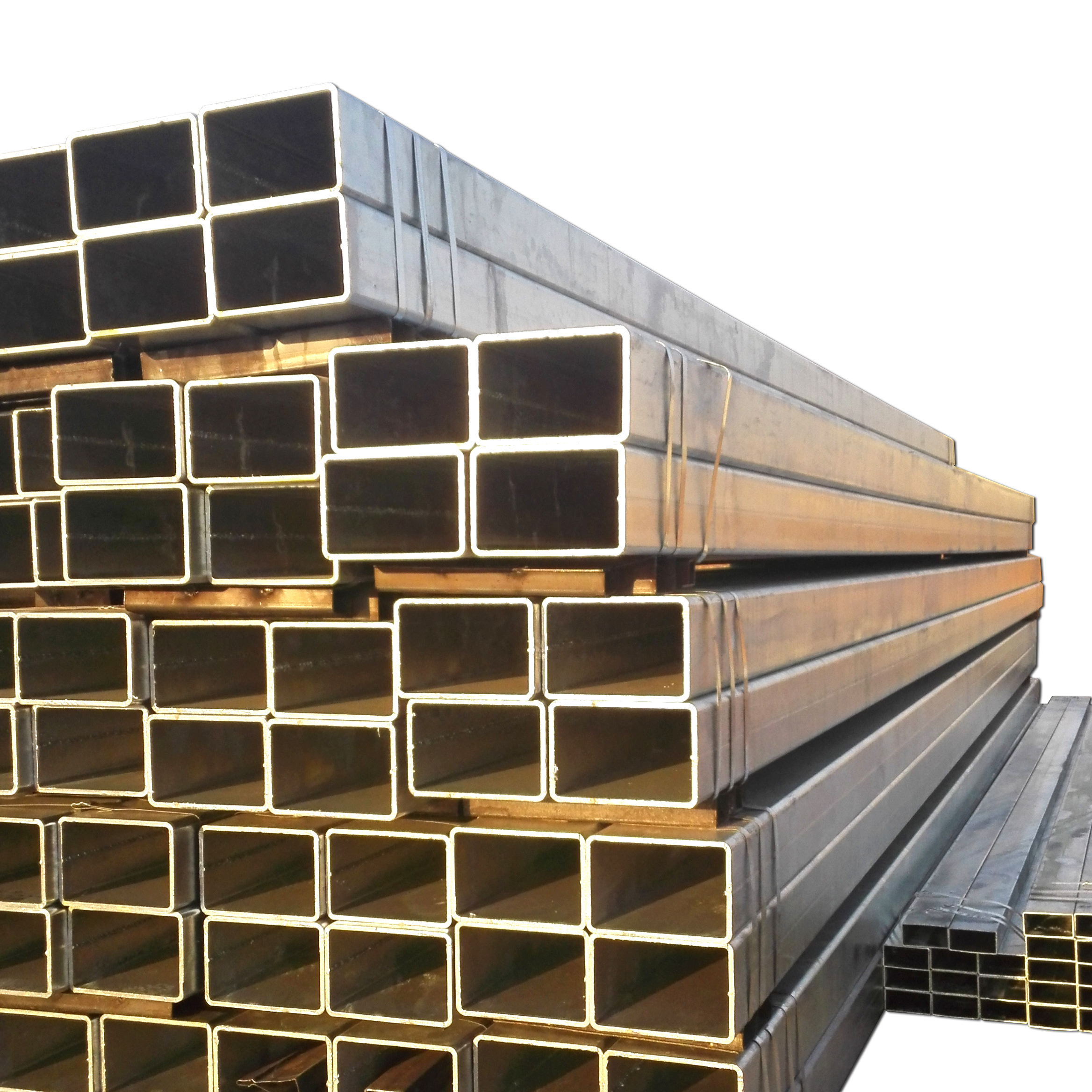

One of the primary benefits of ERW standard pipe is its cost-effectiveness. ERW standard pipe is made from steel coils that are welded together in a continuous process. This eliminates the need for additional Welding and fabrication, resulting in a lower cost of production. Additionally, ERW standard pipe is available in a variety of sizes and thicknesses, making it a versatile option for many industrial applications.

| Chemical Composition | C | Mn | P≤ | S≤ | Si≤ |

| 0.06-0.18 | 0.27-0.63 | 0.035 | 0.035 | 0.25 |

ERW line pipe is also a cost-effective option for industrial applications. It is made from steel coils that are welded together in a continuous process, just like ERW standard pipe. However, ERW line pipe is designed to be used in high-pressure applications, such as Oil and gas pipelines. This makes it an ideal choice for industrial settings where high-pressure systems are needed.

In addition to being cost-effective, ERW standard pipe and ERW line pipe are also highly durable. Both types of pipe are made from steel, which is known for its strength and durability. This makes them ideal for industrial applications where long-term performance is required. Additionally, both types of pipe are resistant to corrosion, making them suitable for use in a variety of environments.

Finally, ERW standard pipe and ERW line pipe are easy to install. Both types of pipe can be cut to size and welded together quickly and easily. This makes them ideal for industrial settings where time is of the essence.

In conclusion, ERW standard pipe and ERW line pipe offer a variety of benefits that make them ideal for industrial applications. They are cost-effective, durable, and easy to install, making them a great choice for many industrial settings.

Comparing the Different Types of ERW Standard Pipe and ERW Line Pipe for Different Projects

ERW (Electric Resistance Welded) standard pipe and ERW line pipe are two distinct types of pipe that are used for different projects. While both types of pipe are made using the same process of electric resistance welding, there are some key differences between them that should be taken into consideration when selecting the right type of pipe for a project.

ERW standard pipe is typically used for low-pressure applications such as water and gas distribution, while ERW line pipe is used for higher-pressure applications such as oil and gas transmission. ERW standard pipe is made from a variety of materials, including Carbon steel, Stainless steel, and Alloy steel, while ERW line pipe is typically made from carbon steel. ERW standard pipe is available in a variety of sizes, ranging from 1/8” to 24”, while ERW line pipe is available in sizes ranging from 2” to 48”.

In addition to the differences in Material and size, there are also differences in the Wall thickness of ERW standard pipe and ERW line pipe. ERW standard pipe typically has a wall thickness of between 0.095” and 0.375”, while ERW line pipe typically has a wall thickness of between 0.312” and 0.500”. The thicker wall of ERW line pipe makes it more suitable for higher-pressure applications than ERW standard pipe.

When selecting the right type of pipe for a project, it is important to consider the differences between ERW standard pipe and ERW line pipe. The material, size, and wall thickness of the pipe should all be taken into consideration in order to ensure that the right type of pipe is selected for the job.