Benefits of Using Food Grade Stainless steel Tube Pipe in the Food Industry

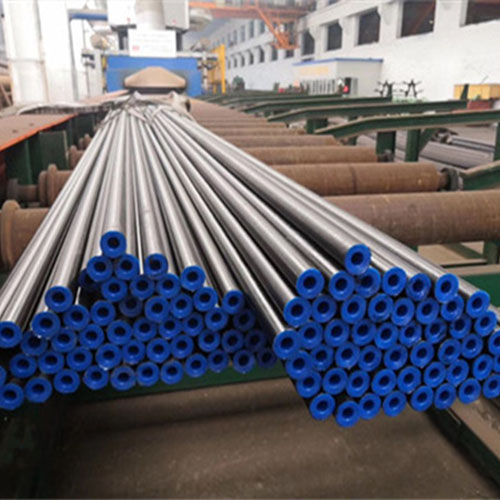

Stainless steel is a popular Material in the food industry due to its many benefits, including its durability, Corrosion resistance, and ease of cleaning. When it comes to food grade stainless Steel tube pipe, there are several options available, including 304, 304L, 316, 316L, 309S, 310S, and 321. These grades of stainless steel are specifically designed for use in the food industry, where hygiene and safety are of utmost importance.

One of the main benefits of using food grade stainless steel tube pipe is its corrosion resistance. Stainless steel is highly resistant to corrosion, making it ideal for use in environments where it may come into contact with acidic or alkaline substances. This is particularly important in the food industry, where food products can be highly acidic or alkaline. By using food grade stainless steel tube pipe, you can ensure that your equipment will not corrode over time, leading to a longer lifespan and reduced maintenance costs.

Another benefit of using food grade stainless steel tube pipe is its durability. Stainless steel is a strong and durable material that can withstand high temperatures and pressures without deforming or breaking. This makes it ideal for use in food processing equipment, where it may be subjected to harsh conditions on a daily basis. By using food grade stainless steel tube pipe, you can ensure that your equipment will last for many years, reducing the need for frequent replacements and repairs.

In addition to its durability and corrosion resistance, food grade stainless steel tube pipe is also easy to clean. Stainless steel has a smooth surface that is resistant to bacteria growth, making it easy to clean and sanitize. This is crucial in the food industry, where cleanliness is paramount to prevent contamination and ensure food safety. By using food grade stainless steel tube pipe, you can easily clean and sanitize your equipment, reducing the risk of foodborne illnesses and ensuring compliance with food safety regulations.

Furthermore, food grade stainless steel tube pipe is non-reactive, meaning that it will not leach any harmful chemicals or substances into food products. This is important in the food industry, where food safety is a top priority. By using food grade stainless steel tube pipe, you can ensure that your food products will not be contaminated by any harmful substances, leading to safer and healthier food for consumers.

Overall, the benefits of using food grade stainless steel tube pipe in the food industry are numerous. From its corrosion resistance and durability to its ease of cleaning and non-reactivity, stainless steel is an ideal material for use in food processing equipment. By choosing food grade stainless steel tube pipe, you can ensure the safety and quality of your food products, while also reducing maintenance costs and increasing the lifespan of your equipment.

Comparison of Different Grades of Sanitary Seamless Stainless Steel Tube Pipe for Food Applications

When it comes to choosing the right material for food processing and handling equipment, stainless steel is often the top choice due to its durability, corrosion resistance, and ease of cleaning. Among the various grades of stainless steel available, 304, 304L, 316, 316L, 309S, 310S, and 321 are commonly used for sanitary seamless stainless steel tube pipes in food applications.

304 and 304L stainless steel are the most widely used grades in the food industry. They are both austenitic stainless steels with a high level of corrosion resistance and good Mechanical properties. The main difference between the two is that 304L has a lower carbon content, which makes it more suitable for Welding applications where carbide precipitation may occur. Both grades are suitable for most food processing applications, but 304L is preferred for welded components.

316 and 316L stainless steel are also popular choices for food-grade applications due to their superior corrosion resistance, especially in acidic environments. These grades contain molybdenum, which enhances their resistance to pitting and crevice corrosion. 316L is the low-carbon version of 316, making it ideal for welding applications. These grades are commonly used in equipment such as tanks, piping, and fittings in food processing plants.

309S and 310S stainless steel are heat-resistant grades that are often used in high-temperature applications in the food industry. These grades have a high chromium and nickel content, which provides excellent oxidation resistance at elevated temperatures. They are commonly used in heat exchangers, furnaces, and other equipment where high temperatures are involved.

321 stainless steel is a stabilized grade that contains titanium, which prevents carbide precipitation during welding. This makes it suitable for applications where welding is required, such as in food processing equipment. 321 stainless steel offers good corrosion resistance and high strength, making it a versatile choice for various food processing applications.

When comparing these different grades of sanitary seamless stainless steel tube pipes for food applications, it is important to consider factors such as corrosion resistance, mechanical properties, weldability, and temperature resistance. 304 and 304L stainless steel are suitable for most food processing applications, while 316 and 316L offer superior corrosion resistance in acidic environments. 309S and 310S are ideal for high-temperature applications, while 321 is a good choice for welding applications.

In conclusion, the choice of grade for sanitary seamless stainless steel tube pipes in food applications depends on the specific requirements of the application. Each grade offers unique properties that make it suitable for different types of food processing equipment. By understanding the characteristics of each grade, manufacturers can select the most appropriate material to ensure the safety and quality of their food products.