Benefits of Using High Pressure MS Seamless Tubes in Industrial Applications

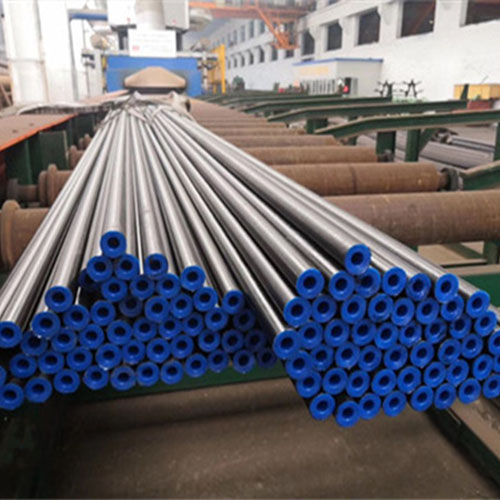

High-pressure MS seamless tubes are an essential component in various industrial applications due to their durability, strength, and reliability. These tubes are made from seamless Carbon steel, which is known for its high Tensile strength and resistance to corrosion. In this article, we will explore the benefits of using high-pressure MS seamless tubes in industrial settings.

One of the key advantages of high-pressure MS seamless tubes is their ability to withstand extreme pressure levels. These tubes are designed to handle high-pressure environments without any risk of leakage or failure. This makes them ideal for use in industries such as Oil and gas, petrochemical, and power generation, where pressure levels can reach several thousand pounds per square inch.

In addition to their high-pressure resistance, MS seamless tubes are also known for their excellent Mechanical properties. These tubes have a smooth and uniform surface, which allows for easy installation and maintenance. They are also highly resistant to bending, cracking, and deformation, making them a reliable choice for critical applications.

Another benefit of using high-pressure MS seamless tubes is their cost-effectiveness. While these tubes may have a higher initial cost compared to other types of piping materials, their long-term durability and low maintenance requirements make them a cost-effective solution in the long run. By investing in high-quality MS seamless tubes, industrial companies can reduce the risk of costly repairs and replacements down the line.

Furthermore, high-pressure MS seamless tubes are versatile and can be used in a wide range of applications. Whether it’s transporting fluids, gases, or steam, these tubes can handle the demands of various industrial processes with ease. Their seamless construction also eliminates the risk of weak points or joints that could compromise the integrity of the system.

In terms of safety, high-pressure MS seamless tubes offer peace of mind to industrial operators. These tubes are manufactured to strict quality standards and undergo rigorous testing to ensure they meet industry regulations and specifications. By using high-quality MS seamless tubes, companies can minimize the risk of accidents, leaks, and downtime, ultimately improving workplace safety and productivity.

Additionally, high-pressure MS seamless tubes are environmentally friendly. Carbon steel is a recyclable Material, which means that these tubes can be repurposed or recycled at the end of their service life. This sustainable approach to manufacturing and disposal aligns with the growing emphasis on environmental responsibility in the industrial sector.

In conclusion, high-pressure MS seamless tubes are a reliable and cost-effective solution for industrial applications that require durability, strength, and safety. These tubes offer numerous benefits, including high-pressure resistance, excellent mechanical properties, versatility, and environmental sustainability. By investing in high-quality MS seamless tubes, industrial companies can ensure the long-term performance and reliability of their systems, ultimately leading to improved efficiency and profitability.

How to Choose the Right Seamless Carbon Steel Pipe for High Pressure Systems

When it comes to high-pressure systems, choosing the right seamless carbon steel pipe is crucial. Seamless carbon steel pipes are known for their strength, durability, and ability to withstand high pressure. In this article, we will discuss the factors to consider when selecting a seamless carbon steel pipe for high-pressure applications.

One of the first things to consider when choosing a seamless carbon steel pipe for high-pressure systems is the material grade. The material grade of the pipe will determine its strength and ability to withstand high pressure. Common material grades for seamless carbon steel pipes include ASTM A106 Grade B, ASTM A333 Grade 6, and API 5L Grade B. These material grades are known for their high tensile strength and resistance to corrosion, making them ideal for high-pressure applications.

Another important factor to consider is the size and thickness of the seamless carbon steel pipe. The size and thickness of the pipe will determine its ability to withstand high pressure. It is important to choose a pipe with the appropriate size and thickness for the specific high-pressure system it will be used in. Thicker pipes are able to withstand higher pressure levels, while larger pipes are able to carry more fluid.

In addition to material grade, size, and thickness, it is also important to consider the manufacturing process of the seamless carbon steel pipe. Seamless pipes are made by piercing a solid billet of steel to create a hollow tube. This manufacturing process results in a pipe with no seams, which makes it stronger and more reliable than welded pipes. When choosing a seamless carbon steel pipe for high-pressure systems, it is important to ensure that it has been manufactured using high-quality materials and processes to ensure its strength and durability.

Furthermore, it is important to consider the end connections of the seamless carbon steel pipe. The end connections of the pipe will determine how it is connected to other components in the high-pressure system. Common end connections for seamless carbon steel pipes include threaded, socket weld, and butt weld connections. It is important to choose the appropriate end connections based on the specific requirements of the high-pressure system.

When selecting a seamless carbon steel pipe for high-pressure systems, it is also important to consider the operating temperature and pressure of the system. Different seamless carbon steel pipes are designed to withstand different temperature and pressure levels. It is important to choose a pipe that is rated for the specific operating conditions of the high-pressure system to ensure its reliability and safety.

In conclusion, choosing the right seamless carbon steel pipe for high-pressure systems is essential to ensure the safety and reliability of the system. Factors to consider when selecting a seamless carbon steel pipe include material grade, size, thickness, manufacturing process, end connections, and operating conditions. By carefully considering these factors, you can choose a seamless carbon steel pipe that meets the requirements of your high-pressure system and provides long-lasting performance.