Benefits of Using High Quality Seamless Pipe in Various Industries

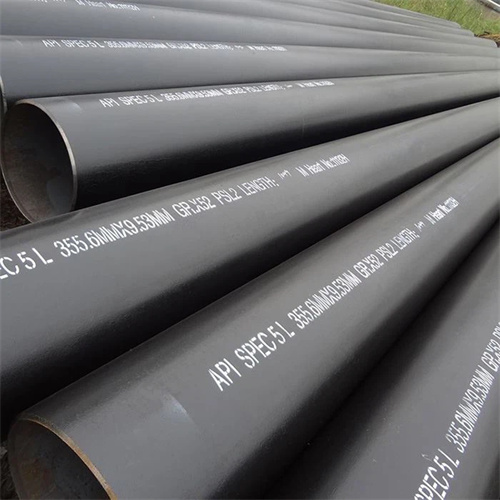

Stainless steel is a versatile Material that is widely used in various industries due to its durability, Corrosion resistance, and aesthetic appeal. When it comes to choosing the right stainless steel pipe for your project, opting for high-quality seamless pipe can offer numerous benefits. Seamless pipes are made by piercing a solid billet of steel and then rolling it to form a hollow tube without any seams or welds. This manufacturing process results in a pipe that is stronger, more reliable, and better suited for high-pressure applications compared to welded pipes.

One of the key advantages of using high-quality seamless pipe is its superior strength. Seamless pipes are able to withstand higher pressure and temperature conditions compared to welded pipes, making them ideal for applications in industries such as Oil and gas, petrochemical, and chemical processing. The absence of welds in seamless pipes eliminates potential weak points that can lead to leaks or failures, ensuring a more reliable and long-lasting piping system.

In addition to their strength, seamless pipes also offer better corrosion resistance compared to welded pipes. The seamless manufacturing process results in a smooth, uniform surface that is less prone to corrosion and pitting, making seamless pipes ideal for use in corrosive environments or applications where hygiene is a concern. This makes seamless pipes a popular choice for industries such as food and beverage, pharmaceutical, and water treatment.

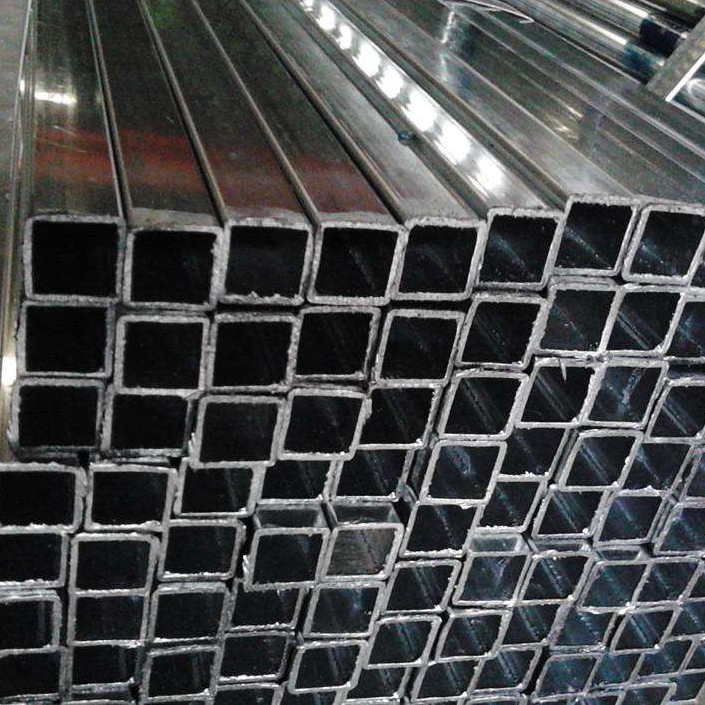

Another benefit of using high-quality seamless pipe is its aesthetic appeal. Seamless pipes have a clean, polished finish that is visually appealing and can enhance the overall look of a project. This makes seamless pipes a popular choice for architectural and decorative applications where appearance is important.

Furthermore, seamless pipes are easier to install and maintain compared to welded pipes. The absence of welds in seamless pipes eliminates the need for time-consuming and costly Welding procedures, making installation faster and more efficient. Additionally, seamless pipes require less maintenance over time, as they are less prone to leaks, cracks, and corrosion compared to welded pipes.

When it comes to choosing a supplier for high-quality seamless pipe, it is important to select a reputable and reliable supplier that offers a wide range of stainless steel grades and sizes to meet your specific requirements. A supplier that carries a comprehensive inventory of seamless pipes in grades such as 304, 304L, 304H, 316, 316L, 316H, 321, 321H, 317L, 347, 347H, 310S, 310, and 310H can provide you with the flexibility and options needed for your project.

In conclusion, high-quality seamless pipe offers numerous benefits for various industries, including superior strength, corrosion resistance, aesthetic appeal, and ease of installation and maintenance. Choosing a reputable supplier that offers a wide range of stainless steel grades and sizes can help ensure that you get the right seamless pipe for your project. Whether you are working in the oil and gas industry, food and beverage industry, or architectural sector, high-quality seamless pipe is a reliable and cost-effective choice for your piping needs.

Comparison of Different Grades of Stainless steel pipes for Various Applications

Stainless steel pipes are widely used in various industries due to their durability, corrosion resistance, and high strength. When it comes to choosing the right grade of stainless steel pipe for a specific application, it is important to consider factors such as the environment in which the pipe will be used, the temperature and pressure requirements, and the desired level of corrosion resistance.

One of the most popular grades of stainless steel pipe is 304, which is known for its excellent corrosion resistance and versatility. It is commonly used in applications where exposure to corrosive chemicals or high temperatures is a concern. 304L is a low-carbon version of 304, which offers improved weldability and formability. 304H, on the other hand, is a high-carbon version of 304, which is specifically designed for high-temperature applications.

Another commonly used grade of stainless steel pipe is 316, which contains molybdenum for increased corrosion resistance. 316L is a low-carbon version of 316, which offers improved weldability and resistance to intergranular corrosion. 316H is a high-carbon version of 316, which is suitable for high-temperature applications.

321 and 321H are titanium-stabilized grades of stainless steel pipe, which offer excellent resistance to intergranular corrosion. They are commonly used in applications where exposure to high temperatures is a concern. 317L is a low-carbon version of 317, which offers improved resistance to sensitization and intergranular corrosion.

347 and 347H are niobium-stabilized grades of stainless steel pipe, which offer excellent resistance to intergranular corrosion. They are commonly used in applications where exposure to high temperatures is a concern. 310S, 310, and 310H are heat-resistant grades of stainless steel pipe, which offer excellent resistance to oxidation and high temperatures.

When comparing different grades of stainless steel pipes, it is important to consider the specific requirements of the application. For example, if corrosion resistance is a primary concern, grades such as 304, 316, and 321 are good options. If high-temperature resistance is a concern, grades such as 304H, 316H, and 310S are suitable choices.

In conclusion, choosing the right grade of stainless steel pipe is essential for ensuring the long-term performance and durability of the application. By considering factors such as corrosion resistance, temperature and pressure requirements, and desired properties, it is possible to select the most suitable grade for the specific application. Whether it is for chemical processing, oil and gas, food processing, or any other industry, high-quality seamless stainless steel pipes are essential for ensuring the success of the project.