Pros and Cons of Using Schedule 40 steel Pipe for Seamless Applications

Schedule 40 steel pipe is a popular choice for a variety of applications due to its durability and strength. However, when it comes to seamless applications, there is some confusion as to whether Schedule 40 steel pipe is truly seamless. In this article, we will explore the pros and cons of using Schedule 40 steel pipe for seamless applications.

First and foremost, it is important to understand the difference between seamless and Welded steel pipe. Seamless steel pipe is made from a solid piece of steel that is heated and then stretched over a form to create a seamless tube. This process results in a pipe that is free of seams or welds, making it ideal for applications where a smooth interior surface is required. On the other hand, welded steel pipe is made by rolling a flat piece of steel into a tube and then Welding the edges together. While welded steel pipe is generally less expensive than seamless steel pipe, it may not be suitable for all applications due to the presence of weld seams.

When it comes to Schedule 40 steel pipe, the term “Schedule” refers to the thickness of the pipe wall. Schedule 40 steel pipe has a relatively thick wall compared to other types of steel pipe, making it ideal for applications where high pressure or high temperature conditions are present. However, some people mistakenly believe that Schedule 40 steel pipe is seamless due to its thickness. In reality, Schedule 40 steel pipe can be either seamless or welded, depending on the manufacturing process used.

One of the main advantages of using Schedule 40 steel pipe for seamless applications is its strength and durability. Schedule 40 steel pipe is designed to withstand high pressure and temperature conditions, making it suitable for a wide range of industrial applications. Additionally, the thick wall of Schedule 40 steel pipe provides added protection against corrosion and abrasion, ensuring a long service life.

Another benefit of using Schedule 40 steel pipe for seamless applications is its versatility. Schedule 40 steel pipe is available in a variety of sizes and lengths, making it easy to find the right pipe for your specific needs. Additionally, Schedule 40 steel pipe can be easily welded or threaded to create custom lengths or configurations, making it a flexible and cost-effective option for a wide range of applications.

Despite its many advantages, there are some drawbacks to using Schedule 40 steel pipe for seamless applications. One potential downside is the cost. Seamless steel pipe is generally more expensive than welded steel pipe due to the additional manufacturing processes involved. Additionally, seamless steel pipe may be harder to find in certain sizes or configurations, making it less convenient for some applications.

In conclusion, Schedule 40 steel pipe is a strong and durable option for seamless applications. While it may not be truly seamless in the traditional sense, Schedule 40 steel pipe offers many benefits, including strength, durability, and versatility. However, it is important to consider the potential drawbacks, such as cost and availability, before choosing Schedule 40 steel pipe for your specific application. Ultimately, the decision to use Schedule 40 steel pipe for seamless applications will depend on your specific needs and budget.

How to Properly Install and Maintain Schedule 40 Steel Pipe for Seamless Projects

Schedule 40 steel pipe is a popular choice for a variety of applications due to its durability and strength. However, one common question that arises when working with this type of pipe is whether it is seamless. In order to properly install and maintain Schedule 40 steel pipe for seamless projects, it is important to understand the characteristics of this Material and how it differs from other types of pipe.

First and foremost, it is important to clarify that Schedule 40 steel pipe is not seamless. Seamless pipe is manufactured by extruding a solid billet through a die to create a hollow tube, whereas Schedule 40 steel pipe is made by welding together multiple pieces of steel to form a continuous pipe. This welding process creates a seam along the Length of the pipe, which can affect its strength and durability.

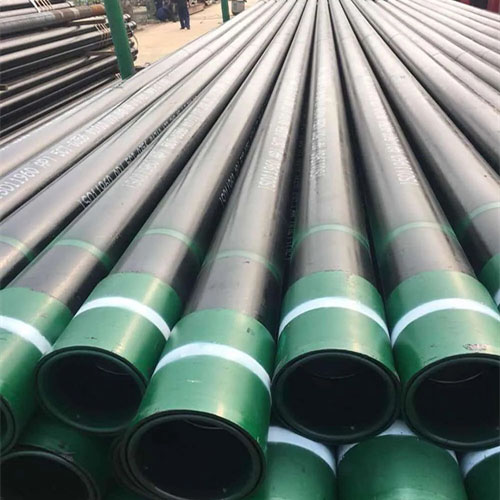

65mm steel pipe

Despite not being seamless, Schedule 40 steel pipe is still a reliable and cost-effective option for many projects. The welded seam in Schedule 40 pipe is typically strong enough to withstand the pressure and stress of most applications, making it suitable for a wide range of uses. However, it is important to take proper precautions when installing and maintaining Schedule 40 steel pipe to ensure its longevity and performance.

When installing Schedule 40 steel pipe, it is important to properly prepare the pipe and fittings before welding them together. This includes cleaning the surfaces to be welded, removing any debris or contaminants, and ensuring a proper fit between the pieces. Proper alignment and fit-up are crucial to creating a strong and leak-free connection that will withstand the test of time.

Once the pipe and fittings are properly prepared, it is important to use the correct welding technique to create a strong and durable seam. This may involve using a specific type of welding process, such as MIG or TIG welding, and ensuring that the weld is done to the proper specifications. Proper welding techniques will help to create a seamless connection between the pieces of pipe, reducing the risk of leaks or failures in the future.

In addition to proper installation, it is also important to maintain Schedule 40 steel pipe to ensure its longevity and performance. This includes regularly inspecting the pipe for signs of wear or damage, such as corrosion or leaks, and addressing any issues promptly. Regular maintenance and upkeep will help to extend the life of the pipe and prevent costly repairs or replacements down the line.

In conclusion, while Schedule 40 steel pipe is not seamless, it is still a reliable and cost-effective option for many projects. By understanding the characteristics of this material and taking proper precautions when installing and maintaining it, you can ensure that your Schedule 40 steel pipe will provide years of reliable service. Proper preparation, welding techniques, and maintenance are key to creating a strong and durable connection that will withstand the test of time.