Benefits of Using Large Diameter SMLS Pipe in Industrial Applications

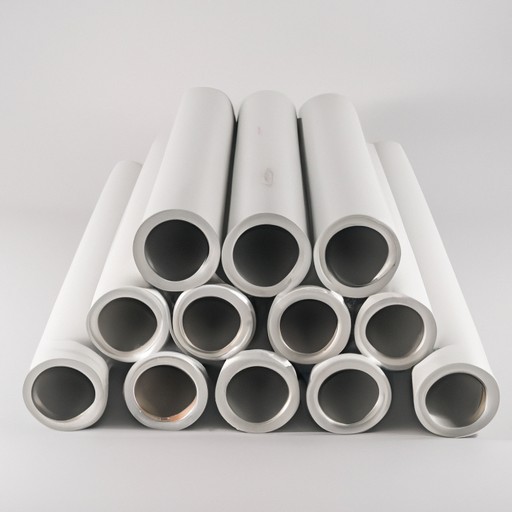

Large diameter Seamless (SMLS) pipes are a crucial component in various industrial applications due to their durability, strength, and versatility. These pipes are manufactured without any seams or welds, making them ideal for high-pressure and high-temperature environments. In this article, we will explore the benefits of using large diameter SMLS pipes, specifically ASTM A106 Gr. B Q235 A53 Sch40 hot rolled/Cold drawn galvanized Gi/Gl black iron round/square carbon seamless steel precision SS pipes.

One of the key advantages of large diameter SMLS pipes is their superior strength and durability. These pipes are able to withstand extreme pressure and temperature conditions, making them ideal for use in industries such as Oil and gas, petrochemical, and power generation. The seamless construction of these pipes eliminates the weak points that are often found in welded pipes, ensuring a higher level of reliability and safety.

In addition to their strength, large diameter SMLS pipes also offer excellent Corrosion resistance. The galvanized coating on these pipes provides an extra layer of protection against rust and corrosion, ensuring a longer lifespan and reduced maintenance costs. This makes them a cost-effective solution for industries that require long-term durability and performance.

Furthermore, large diameter SMLS pipes are known for their smooth interior surface, which allows for efficient fluid flow and reduced pressure drop. This is particularly important in industries where the flow of liquids or gases is critical, such as in chemical processing plants or refineries. The seamless construction of these pipes also eliminates the risk of leaks or failures, ensuring a consistent and reliable flow of materials.

Another benefit of using large diameter SMLS pipes is their versatility. These pipes can be easily customized to meet specific requirements, such as different wall thicknesses, lengths, or diameters. This flexibility makes them suitable for a wide range of applications, from transporting water and gas to carrying abrasive materials or corrosive chemicals.

Additionally, large diameter SMLS pipes are easy to install and maintain, thanks to their lightweight and compact design. This makes them a practical choice for projects that require quick and efficient installation, reducing downtime and labor costs. The seamless construction of these pipes also eliminates the need for frequent repairs or replacements, further reducing maintenance expenses over time.

In conclusion, large diameter SMLS pipes offer a range of benefits that make them an ideal choice for industrial applications. From their superior strength and durability to their corrosion resistance and smooth interior surface, these pipes provide a reliable and cost-effective solution for industries that require high-performance piping systems. Whether used in oil and gas, petrochemical, or power generation industries, large diameter SMLS pipes are a versatile and efficient option that can meet the demands of even the most challenging environments.

Comparison of ASTM A106 Gr. B, Q235, and A53 Sch40 Hot Rolled/Cold Drawn Galvanized Gi/Gl Black Iron Round/Square Carbon Seamless Steel Precision Ss Pipe

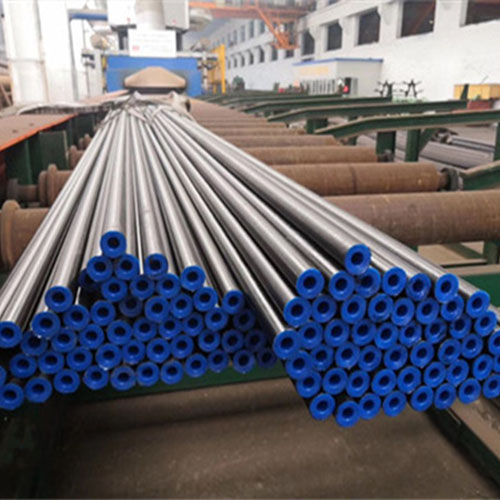

Large diameter seamless pipes are essential components in various industries, including oil and gas, construction, and manufacturing. When it comes to choosing the right type of seamless pipe for a specific application, factors such as Material composition, manufacturing process, and quality standards play a crucial role. In this article, we will compare three popular types of large diameter seamless pipes: ASTM A106 Gr. B, Q235, and A53 Sch40 hot rolled/cold drawn galvanized Gi/Gl black iron round/square carbon seamless steel precision SS pipe.

ASTM A106 Gr. B is a seamless Carbon steel pipe designed for high-temperature service. It is commonly used in refineries, power plants, and chemical plants where high temperatures and pressures are present. The material composition of ASTM A106 Gr. B includes carbon, manganese, phosphorus, sulfur, and silicon. This combination of elements gives the pipe excellent Mechanical properties, such as high Tensile strength and good weldability.

Q235 is a Chinese standard carbon structural steel that is widely used in various industries. Q235 seamless pipes are known for their high strength, good toughness, and excellent weldability. The material composition of Q235 includes carbon, manganese, silicon, and sulfur. Q235 seamless pipes are commonly used in construction, machinery, and transportation industries due to their versatility and cost-effectiveness.

A53 Sch40 hot rolled/cold drawn galvanized Gi/Gl black iron round/square carbon seamless steel precision SS pipe is a versatile type of seamless pipe that can be used in a wide range of applications. The A53 specification covers seamless and welded black and hot-dipped galvanized steel pipe. A53 seamless pipes are known for their durability, corrosion resistance, and high strength. They are commonly used in plumbing, HVAC, and fire protection systems.

When it comes to manufacturing processes, ASTM A106 Gr. B seamless pipes are typically produced using Hot rolling or cold drawing techniques. Hot rolling involves heating the steel billet to high temperatures and then passing it through rollers to shape it into a pipe. Cold drawing, on the other hand, involves pulling the steel billet through a die to form a seamless pipe. Both processes result in high-quality seamless pipes with smooth surfaces and precise dimensions.

Q235 seamless pipes are also manufactured using hot rolling or cold drawing techniques. These processes help to improve the mechanical properties of the steel and ensure uniformity in the pipe’s dimensions. Q235 seamless pipes are known for their excellent surface finish and dimensional accuracy, making them suitable for a wide range of applications.

A53 Sch40 hot rolled/cold drawn galvanized Gi/Gl black iron round/square carbon seamless steel precision SS pipe is typically produced using hot rolling or cold drawing techniques as well. The galvanization process involves coating the steel pipe with a layer of zinc to protect it from corrosion. This makes A53 seamless pipes ideal for outdoor applications where exposure to moisture and harsh weather conditions is a concern.

In conclusion, ASTM A106 Gr. B, Q235, and A53 Sch40 hot rolled/cold drawn galvanized Gi/Gl black iron round/square carbon seamless steel precision SS pipe are all popular choices for large diameter seamless pipes. Each type has its own unique properties and advantages, making them suitable for different applications. Whether you need a high-temperature resistant pipe for industrial applications or a cost-effective solution for construction projects, there is a seamless pipe option that meets your requirements.