Advantages of Using Carbon steel A106 B Seamless Pipes

Carbon steel A106 B seamless pipes are a popular choice in various industries due to their numerous advantages. These pipes are known for their durability, strength, and resistance to corrosion, making them ideal for a wide range of applications. In this article, we will explore the advantages of using carbon steel A106 B seamless pipes and why they are a preferred choice for many industries.

One of the key advantages of carbon steel A106 B seamless pipes is their high strength-to-Weight ratio. These pipes are made from a combination of carbon and iron, which gives them the strength needed to withstand high pressure and temperature conditions. This makes them ideal for use in applications where strength and durability are essential, such as in the Oil and gas industry.

Another advantage of carbon steel A106 B seamless pipes is their resistance to corrosion. These pipes are coated with a protective layer that prevents rust and corrosion, ensuring that they have a long lifespan and require minimal maintenance. This makes them a cost-effective option for industries looking to reduce maintenance costs and downtime.

In addition to their strength and Corrosion resistance, carbon steel A106 B seamless pipes are also known for their versatility. These pipes can be easily cut to Length, making them suitable for a wide range of applications. Whether you need a short length of Pipe for a small project or a longer length for a larger application, carbon steel A106 B seamless pipes can be customized to meet your specific requirements.

Furthermore, carbon steel A106 B seamless pipes are easy to install and require minimal Welding. This makes them a convenient option for industries looking to save time and labor costs during installation. Additionally, the seamless design of these pipes ensures a smooth flow of fluids, making them ideal for applications where efficiency is crucial.

Another advantage of using carbon steel A106 B seamless pipes is their affordability. Compared to other materials, such as Stainless steel or alloy, carbon steel pipes are more cost-effective, making them a budget-friendly option for industries looking to save on Material costs. Despite their affordability, carbon steel A106 B seamless pipes offer high performance and durability, making them a reliable choice for various applications.

In conclusion, carbon steel A106 B seamless pipes offer numerous advantages that make them a preferred choice for many industries. From their high strength-to-weight ratio and resistance to corrosion to their versatility and affordability, these pipes are a reliable option for a wide range of applications. Whether you are in the oil and gas industry, construction, or manufacturing, carbon steel A106 B seamless pipes are a durable and cost-effective solution for your piping needs.

How to Properly Cut and Import Carbon Steel A106 B Seamless Pipes to Length

Carbon steel pipes are a popular choice in various industries due to their durability, strength, and cost-effectiveness. Among the different types of carbon steel pipes available in the market, A106 B seamless pipes are highly sought after for their seamless construction, which ensures a smooth flow of fluids and gases. However, when it comes to using these pipes in specific projects, it is often necessary to cut them to a specific length to meet the requirements of the application.

Cutting carbon steel A106 B seamless pipes to length requires precision and expertise to ensure that the pipes are cut accurately without compromising their structural integrity. In this article, we will discuss the proper techniques for cutting carbon steel A106 B seamless pipes to length and the process of importing these pipes for your project.

When it comes to cutting carbon steel A106 B seamless pipes to length, there are several methods that can be used depending on the size and thickness of the pipes. One of the most common methods is using a pipe cutting machine, which is specifically designed to cut pipes with precision and accuracy. These machines use a rotating blade to cut through the pipe, ensuring a clean and straight cut.

Another method that can be used to cut carbon steel A106 B seamless pipes to length is using a handheld pipe cutter. This tool is ideal for cutting smaller pipes or pipes that are in hard-to-reach areas. Handheld pipe cutters are easy to use and provide a clean cut, making them a popular choice for smaller projects.

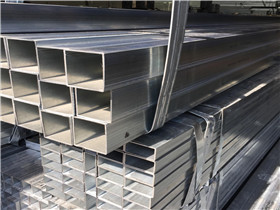

square tube railing

Regardless of the method used, it is essential to measure the pipe accurately before cutting to ensure that the pipe is cut to the correct length. Taking accurate measurements will help prevent any errors and ensure that the pipes fit perfectly into the project.

Once the carbon steel A106 B seamless pipes have been cut to length, the next step is to import them for use in your project. Importing pipes can be a complex process, especially when dealing with international suppliers. It is essential to work with a reputable supplier who can provide high-quality pipes and ensure that they meet the required specifications.

When importing carbon steel A106 B seamless pipes, it is crucial to consider factors such as shipping costs, customs duties, and import regulations. Working with a supplier who has experience in importing pipes can help streamline the process and ensure that the pipes are delivered on time and within budget.

In conclusion, cutting carbon steel A106 B seamless pipes to length requires precision and expertise to ensure that the pipes are cut accurately without compromising their structural integrity. By using the proper cutting techniques and working with a reputable supplier, you can import high-quality pipes for your project and ensure that they meet the required specifications. Whether you are working on a small-scale project or a large industrial application, properly cutting and importing carbon steel A106 B seamless pipes to length is essential for the success of your project.