Benefits of Using Seamless Pipe in Industrial Applications

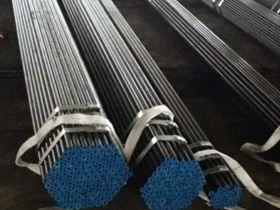

Seamless pipes are a crucial component in various industrial applications due to their numerous benefits. These pipes are manufactured without any Welding seam, which makes them stronger and more reliable than welded pipes. The seamless pipe manufacturing process involves extruding a solid billet through a die to create a hollow tube. This results in a pipe with uniform thickness and consistent quality throughout its Length.

One of the key advantages of using seamless pipes in industrial applications is their superior strength. Since seamless pipes do not have any welded seams, they are able to withstand higher pressure and temperature than welded pipes. This makes them ideal for applications that require high pressure or temperature resistance, such as in the Oil and gas industry.

Another benefit of seamless pipes is their smooth interior surface. The absence of weld seams eliminates the risk of corrosion and erosion, which can occur at the weld joints of welded pipes. This smooth surface also reduces friction and allows for better flow of fluids through the pipe, making seamless pipes more efficient for transporting liquids and gases.

2 inch dom tubingSeamless pipes are also known for their durability and longevity. The absence of weld seams eliminates weak points in the pipe, making it less prone to failure or leakage. This results in a longer service life and lower maintenance costs for industrial applications. Additionally, seamless pipes are easier to inspect and test for defects, ensuring that they meet the required quality standards.

In addition to their strength and durability, seamless pipes offer greater flexibility in design and customization. Manufacturers can produce seamless pipes in a wide range of sizes, shapes, and materials to meet the specific requirements of different industrial applications. This versatility makes seamless pipes suitable for a variety of industries, including construction, automotive, aerospace, and power generation.

Seamless pipes are also more cost-effective in the long run compared to welded pipes. While the initial cost of seamless pipes may be higher, their superior quality and performance result in lower maintenance and replacement costs over time. This makes seamless pipes a cost-efficient choice for industrial applications that require reliable and durable piping solutions.

Overall, seamless pipes offer a range of benefits that make them an ideal choice for industrial applications. Their superior strength, smooth interior surface, durability, and customization options make them a reliable and efficient piping solution for a variety of industries. By choosing seamless pipes, industrial companies can ensure the safety, efficiency, and longevity of their piping systems.