Benefits of Using Seamless steel Pipe for Industrial Applications

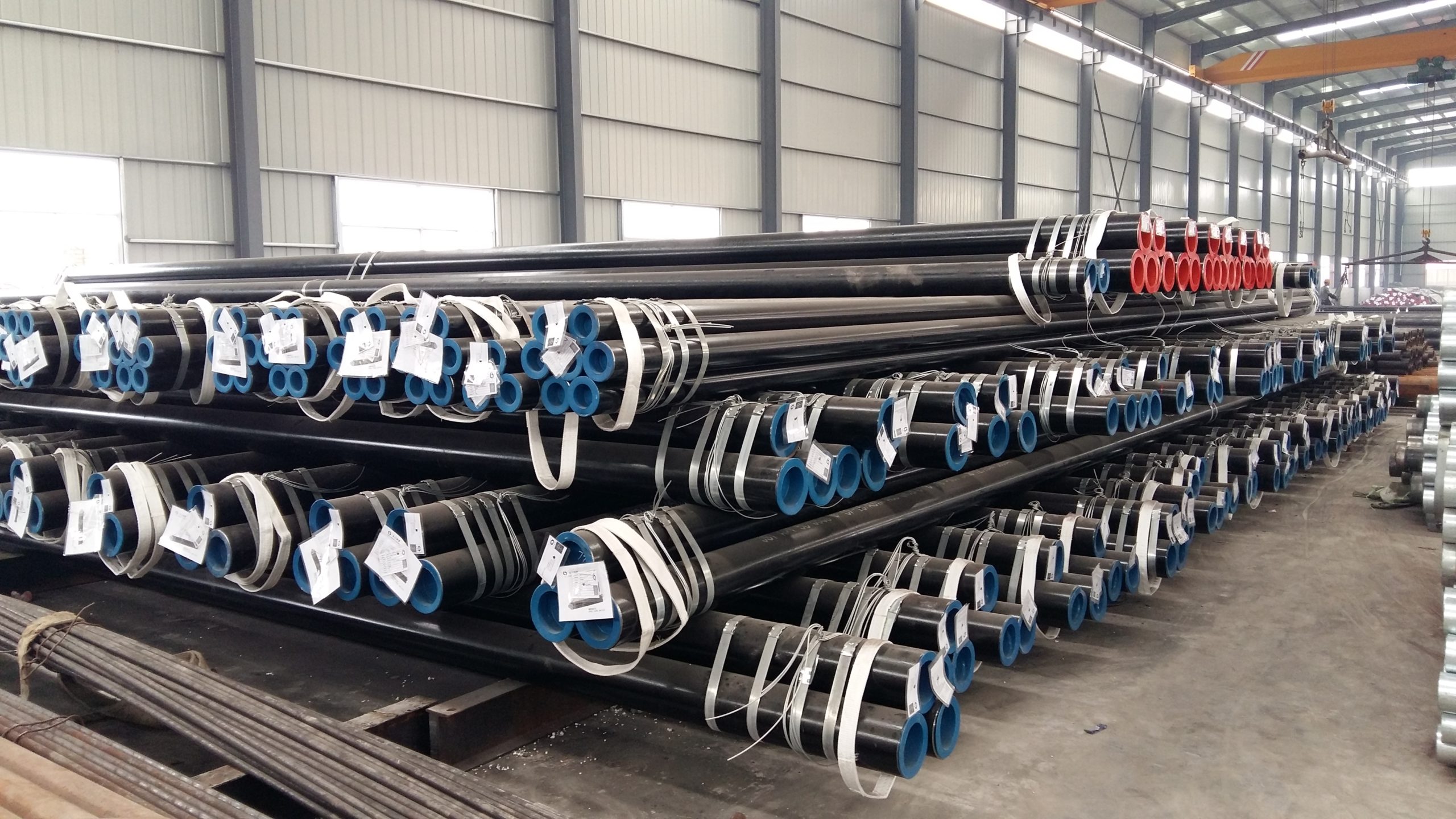

Seamless steel pipes, particularly those with a 12mm outer diameter and 8mm inner diameter, have become indispensable components in various industrial applications. The seamless construction of these pipes offers a multitude of benefits, making them preferred choices in sectors ranging from Oil and gas to automotive and construction.

https://youtube.com/watch?v=6tUfn1bKo9YOne of the primary advantages of seamless steel pipes lies in their superior strength and durability. Unlike welded pipes, seamless ones are formed from a single piece of steel without any joints or seams. This seamless construction eliminates weak points, reducing the risk of leaks, cracks, or failures under high pressure or stress conditions. As a result, seamless steel pipes offer enhanced reliability and longevity, making them suitable for demanding industrial environments.

Moreover, the absence of weld seams in seamless pipes improves their Corrosion resistance. Welded pipes are prone to corrosion at the weld seams due to differences in Material composition and the presence of heat-affected zones. In contrast, seamless steel pipes exhibit uniform composition throughout, providing better resistance to corrosive elements such as chemicals, moisture, and abrasive materials. This corrosion resistance extends the service life of seamless pipes, reducing maintenance costs and downtime for industrial operations.

ss 304 16 gauge pipe price

Another significant benefit of seamless steel pipes is their smooth internal surface finish. The seamless manufacturing process produces pipes with consistent dimensions and smooth bore surfaces, minimizing frictional resistance and pressure drops in fluid flow applications. This smooth interior also reduces the accumulation of debris, sediment, and scale, thereby maintaining optimal flow rates and preventing clogs or blockages in pipelines.

Furthermore, seamless steel pipes offer excellent dimensional accuracy and tolerances, ensuring tight fits and seamless integration into complex industrial systems. Whether used for conveying fluids, gases, or solids, precise pipe dimensions are crucial for seamless operation and compatibility with valves, fittings, and other components. The uniformity of seamless pipes facilitates easy installation, reducing assembly time and labor costs for industrial projects.

Additionally, seamless steel pipes are capable of withstanding extreme temperatures and pressures, making them suitable for high-performance applications in harsh operating conditions. Whether subjected to freezing temperatures or high-temperature environments, seamless pipes maintain their structural integrity and Mechanical properties, ensuring reliable performance under challenging circumstances.

Moreover, the versatility of seamless steel pipes extends to their compatibility with various fabrication processes and surface treatments. Manufacturers can customize seamless pipes to meet specific requirements regarding Wall thickness, outer diameter, and surface finishes, enabling seamless integration into diverse industrial applications. Whether for structural support, fluid transport, or mechanical conveyance, seamless steel pipes offer versatility and adaptability to meet the evolving needs of different industries.

In conclusion, the benefits of using seamless steel pipes, particularly those with a 12mm outer diameter and 8mm inner diameter, are numerous and significant for industrial applications. From enhanced strength and durability to superior corrosion resistance and smooth internal surfaces, seamless pipes offer unmatched performance and reliability in demanding environments. Their precise dimensions, tolerance, and versatility make seamless steel pipes indispensable components in various sectors, contributing to improved efficiency, safety, and sustainability in industrial operations.