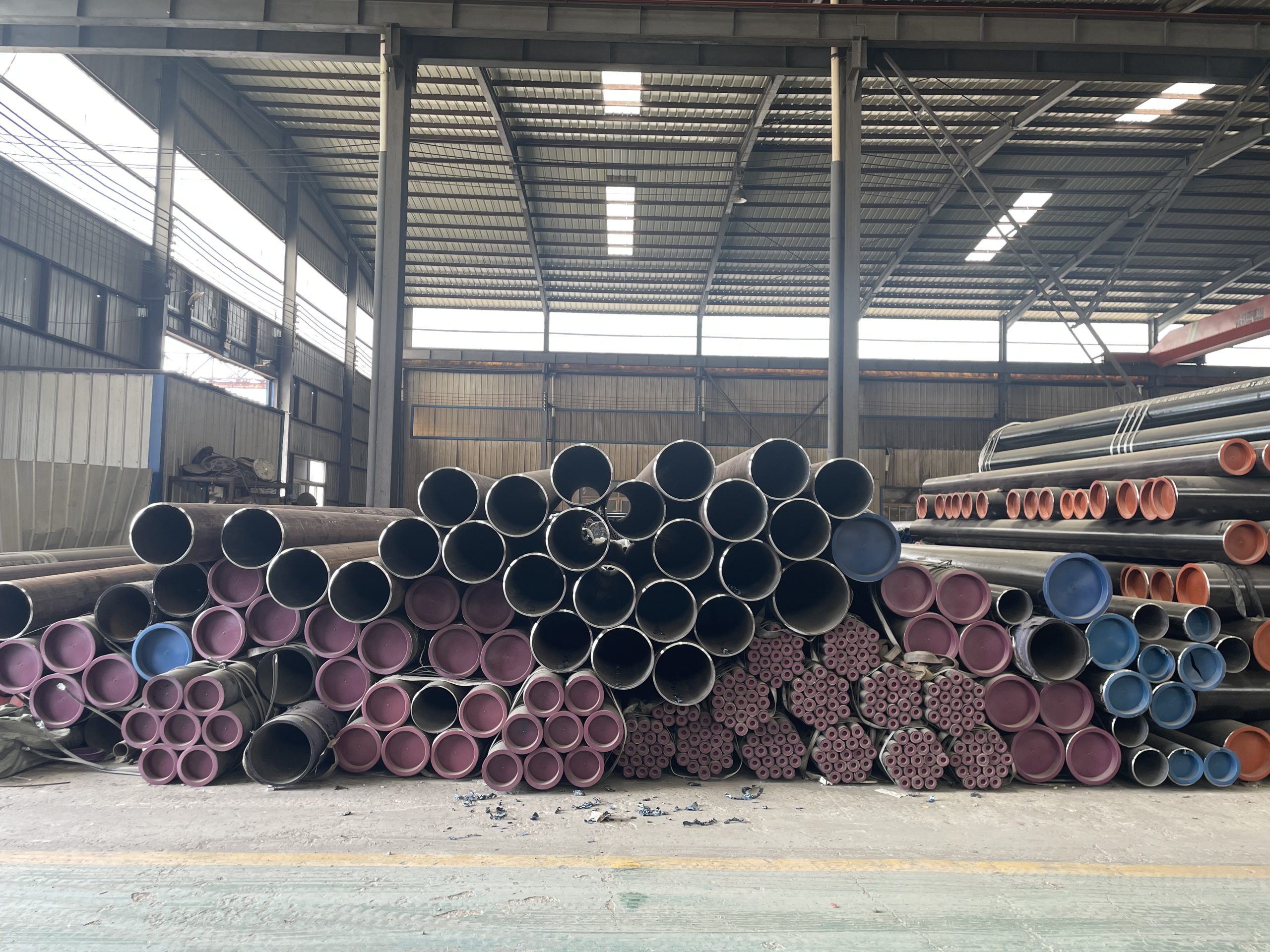

Advantages of Seamless steel Pipes for Various Industrial Applications

Seamless steel pipes are a vital component in various industrial applications, offering a range of advantages that make them indispensable in numerous sectors. From Oil and gas exploration to automotive manufacturing, seamless steel pipes play a crucial role in ensuring the efficiency, reliability, and safety of operations. Here, we explore the key advantages of seamless steel pipes and their significance across different industries.

One of the primary benefits of seamless steel pipes is their exceptional strength and durability. Unlike welded pipes, which are prone to defects and weaknesses at the welded seams, seamless pipes are manufactured from a solid steel billet, ensuring uniformity and consistency in their structure. This results in pipes that can withstand high pressure, extreme temperatures, and harsh operating conditions without compromising their integrity.

In addition to their strength, seamless steel pipes offer superior Corrosion resistance, making them ideal for applications where exposure to corrosive substances is a concern. The absence of welded seams eliminates potential weak points where corrosion can initiate, ensuring long-term performance and reliability. This corrosion resistance is particularly advantageous in industries such as oil and gas, chemical processing, and marine engineering, where exposure to corrosive environments is common.

a790 s31803

Another significant advantage of seamless steel pipes is their smooth interior surface, which facilitates efficient fluid flow. The absence of welded seams reduces friction and turbulence within the Pipe, allowing for more efficient transportation of liquids and gases. This smooth flow is crucial in industries such as petrochemicals, where even minor reductions in flow resistance can result in significant energy savings and operational efficiencies.

Furthermore, seamless steel pipes offer greater flexibility and versatility in design and installation compared to welded pipes. Their uniformity in composition and structure allows for seamless integration into complex piping systems, reducing the need for additional fittings and connectors. This not only streamlines the installation process but also minimizes the risk of leaks and failures associated with welded joints.

The seamless manufacturing process also results in pipes with precise dimensions and tolerances, ensuring tight seals and optimal performance in critical applications. Whether it’s conveying high-pressure steam in power plants or transporting volatile chemicals in refineries, the reliability and consistency of seamless steel pipes are essential for maintaining safety and operational efficiency.

Moreover, seamless steel pipes are highly resistant to fatigue and cracking, making them suitable for applications subjected to cyclic loading and stress. This Fatigue resistance is particularly crucial in industries such as construction and infrastructure, where pipes are exposed to dynamic forces and vibrations over extended periods.

In conclusion, seamless steel pipes offer a host of advantages that make them the preferred choice for various industrial applications. Their strength, durability, corrosion resistance, smooth interior surface, and versatility make them indispensable in industries ranging from oil and gas to construction and manufacturing. By providing reliable performance under demanding conditions, seamless steel pipes play a vital role in supporting the infrastructure, production, and economic growth of nations around the world.