Benefits of Seamless Welded Mirror Polished/Polishing for Heat Exchanger

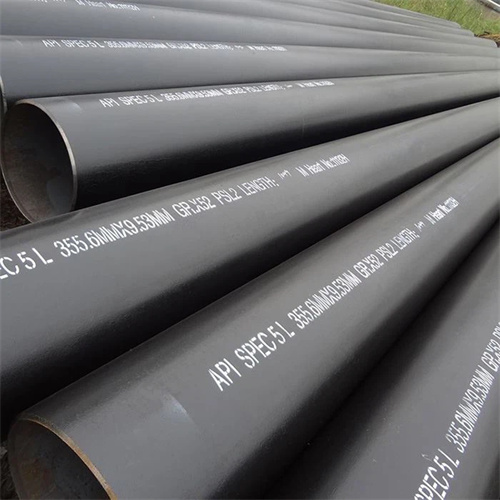

When it comes to heat exchangers, the quality of the materials used plays a crucial role in the efficiency and longevity of the equipment. Stainless steel is a popular choice for heat exchangers due to its durability, Corrosion resistance, and ability to withstand high temperatures. However, not all stainless steel tubes and pipes are created equal. Seamless welded mirror polished or polishing for heat exchangers offers a number of benefits that make it a superior choice for this application.

One of the main advantages of seamless welded mirror polished or polishing stainless steel tubes and pipes is their smooth surface finish. The mirror-polished finish not only enhances the aesthetic appeal of the equipment but also has practical benefits. The smooth surface reduces friction, which in turn improves the flow of fluids through the heat exchanger. This results in better heat transfer efficiency and lower energy consumption, making the equipment more cost-effective to operate.

In addition to improved heat transfer efficiency, seamless welded mirror polished or polishing stainless steel tubes and pipes also offer superior corrosion resistance. The mirror-polished finish creates a protective barrier that helps prevent corrosion and rust, even in harsh environments. This extends the lifespan of the heat exchanger and reduces the need for frequent maintenance and repairs, saving time and money in the long run.

Furthermore, seamless welded mirror polished or polishing stainless steel tubes and pipes are hygienic and easy to clean. The smooth surface finish prevents bacteria and other contaminants from adhering to the surface, making it ideal for applications where cleanliness is a priority, such as in the food and pharmaceutical industries. The mirror-polished finish also makes it easier to visually inspect the equipment for any signs of wear or damage, ensuring that it remains in optimal working condition.

Another benefit of seamless welded mirror polished or polishing stainless steel tubes and pipes is their versatility. They can be used in a wide range of applications, from industrial heat exchangers to decorative architectural elements. The high-quality finish and durability of these tubes and pipes make them suitable for both functional and aesthetic purposes, giving designers and engineers more flexibility in their projects.

At Stainless Steel tube Pipe, we offer a wide selection of seamless welded mirror polished or polishing stainless steel tubes and pipes in various grades, including ASTM DIN 304/304L/321/316/316L/316ti/347. Our products are manufactured to the highest standards of quality and precision, ensuring reliable performance and long-lasting durability. And now, for a limited time, we are offering a special discount of 10% off on all our seamless welded mirror polished or polishing stainless steel tubes and pipes for heat exchangers.

In conclusion, seamless welded mirror polished or polishing stainless steel tubes and pipes offer a number of benefits for heat exchangers, including improved heat transfer efficiency, superior corrosion resistance, easy maintenance, and versatility. With their high-quality finish and durability, these tubes and pipes are a cost-effective and reliable choice for a wide range of applications. Take advantage of our special discount and upgrade your heat exchanger with seamless welded mirror polished or polishing stainless steel tubes and pipes from Stainless Steel Tube Pipe today.