Advantages of Using St35, St45, St52/E355, E215, E235 steel Pipes in Industrial Applications

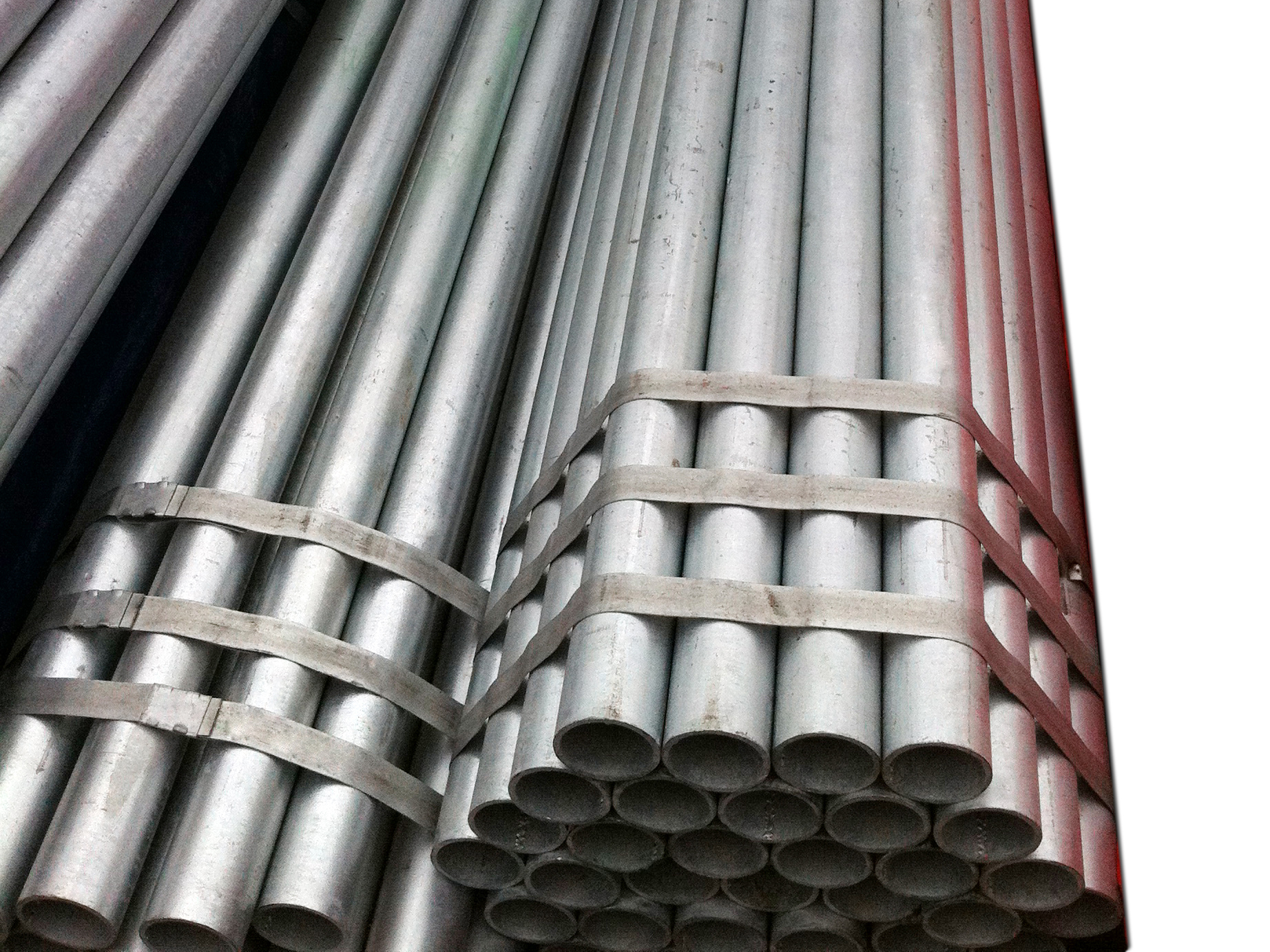

Steel pipes are an essential component in various industrial applications, providing a reliable and durable solution for transporting fluids and gases. Among the different types of steel pipes available, St35, St45, St52/E355, E215, E235, 10#, 20#, and 45# steel pipes are widely used due to their numerous advantages.

One of the key advantages of using St35, St45, St52/E355, E215, E235 steel pipes is their high strength and durability. These steel pipes are made from high-quality materials that are designed to withstand high pressure and temperature conditions, making them ideal for use in demanding industrial environments. Whether it’s transporting Oil, gas, water, or chemicals, these steel pipes can handle the rigors of industrial applications with ease.

In addition to their strength, St35, St45, St52/E355, E215, E235 steel pipes are also known for their excellent Corrosion resistance. This is particularly important in industries where the pipes are exposed to harsh chemicals or corrosive environments. By using steel pipes that are resistant to corrosion, companies can avoid costly repairs and replacements, ensuring the longevity of their infrastructure.

Furthermore, St35, St45, St52/E355, E215, E235 steel pipes are known for their versatility and flexibility. These pipes can be easily welded, bent, and fabricated to meet specific project requirements, making them a popular choice for a wide range of industrial applications. Whether it’s constructing pipelines, building structures, or manufacturing machinery, these steel pipes offer the flexibility needed to accommodate various design specifications.

Another advantage of using St35, St45, St52/E355, E215, E235 steel pipes is their cost-effectiveness. While the initial investment may be higher compared to other types of pipes, the long-term benefits far outweigh the upfront costs. With their durability and low maintenance requirements, these steel pipes offer a cost-effective solution for companies looking to minimize operational expenses and maximize efficiency.

Moreover, St35, St45, St52/E355, E215, E235 steel pipes are known for their high performance and reliability. These pipes are manufactured to meet strict quality standards, ensuring consistent performance and reliability in industrial applications. Whether it’s transporting fluids at high temperatures or pressures, these steel pipes can be relied upon to deliver optimal performance without compromising safety or efficiency.

In conclusion, St35, St45, St52/E355, E215, E235 steel pipes offer a wide range of advantages that make them an ideal choice for industrial applications. From their high strength and durability to their corrosion resistance and cost-effectiveness, these steel pipes provide a reliable and efficient solution for transporting fluids and gases in demanding environments. With their versatility, flexibility, and high performance, St35, St45, St52/E355, E215, E235 steel pipes continue to be a popular choice among industries looking for a durable and reliable piping solution.

Comparison of Mechanical properties of St35, St45, St52/E355, E215, E235 Steel Pipes with 10# 20# 45# Steel Pipes

Steel pipes are an essential component in various industries, including construction, automotive, and manufacturing. When it comes to choosing the right type of steel Pipe for a specific application, it is crucial to consider the mechanical properties of the Material. In this article, we will compare the mechanical properties of St35, St45, St52/E355, E215, E235 steel pipes with 10#, 20#, 45# steel pipes.

St35, St45, St52/E355, E215, E235 are all Seamless Carbon steel pipes that are commonly used in structural applications. These pipes are known for their high strength, durability, and resistance to corrosion. The mechanical properties of these steel pipes are determined by factors such as the chemical composition, heat treatment, and manufacturing process.

St35 steel pipe is a low carbon steel pipe that is known for its excellent weldability and formability. It has a minimum Yield strength of 235 MPa and a minimum Tensile strength of 360-510 MPa. St45 steel pipe, on the other hand, has a higher carbon content than St35, which gives it increased strength and Hardness. It has a minimum yield strength of 245 MPa and a minimum tensile strength of 410-530 MPa.

St52/E355 steel pipe is a high-strength, low-Alloy steel pipe that is commonly used in mechanical and structural applications. It has a minimum yield strength of 355 MPa and a minimum tensile strength of 490-630 MPa. E215 and E235 steel pipes are also low carbon steel pipes that are known for their good weldability and formability. E215 has a minimum yield strength of 215 MPa, while E235 has a minimum yield strength of 235 MPa.

In comparison, 10#, 20#, 45# steel pipes are carbon steel pipes that are commonly used in general engineering applications. 10# steel pipe has a minimum yield strength of 205 MPa and a minimum tensile strength of 335 MPa. 20# steel pipe has a minimum yield strength of 245 MPa and a minimum tensile strength of 410 MPa. 45# steel pipe has a minimum yield strength of 335 MPa and a minimum tensile strength of 570 MPa.

When comparing the mechanical properties of St35, St45, St52/E355, E215, E235 steel pipes with 10#, 20#, 45# steel pipes, it is evident that the former group of steel pipes generally has higher strength and hardness values. This makes them more suitable for applications that require high strength and durability, such as structural components in buildings and bridges.

Additionally, the seamless nature of St35, St45, St52/E355, E215, E235 steel pipes makes them more resistant to corrosion and leakage compared to welded steel pipes. This is important in applications where the pipes are exposed to harsh environmental conditions or corrosive substances.

In conclusion, when choosing between St35, St45, St52/E355, E215, E235 steel pipes and 10#, 20#, 45# steel pipes, it is important to consider the specific requirements of the application. While both types of steel pipes have their own advantages and disadvantages, the former group of steel pipes generally offers higher strength, durability, and resistance to corrosion. Ultimately, the choice of steel pipe will depend on factors such as the load-bearing capacity, environmental conditions, and budget constraints of the project.