Benefits of Using Stainless steel pipes in Industrial Applications

Stainless steel pipes are a popular choice in various industrial applications due to their numerous benefits. These pipes are known for their durability, Corrosion resistance, and high strength, making them ideal for use in demanding environments. In addition, stainless steel pipes are easy to maintain and have a long lifespan, making them a cost-effective option for many industries.

One of the key benefits of using stainless steel pipes is their resistance to corrosion. Unlike other materials such as Carbon steel or iron, stainless steel does not rust or corrode easily, even when exposed to harsh chemicals or extreme temperatures. This makes stainless steel pipes a reliable choice for applications where corrosion resistance is essential, such as in the chemical, petrochemical, and food processing industries.

Another advantage of stainless steel pipes is their high strength-to-Weight ratio. Stainless steel is a strong Material that can withstand heavy loads and high pressures without deforming or breaking. This makes stainless steel pipes suitable for use in structural applications, such as in construction and infrastructure projects, where strength and durability are crucial.

Stainless steel pipes are also known for their hygienic properties, making them a popular choice in the food and beverage industry. Stainless steel is non-porous and easy to clean, making it resistant to bacteria growth and contamination. This makes stainless steel pipes ideal for transporting food and beverages safely and efficiently, without the risk of contamination.

In addition to their durability and corrosion resistance, stainless steel pipes are also easy to maintain. Unlike other materials that require regular painting or coating to prevent corrosion, stainless steel pipes require minimal maintenance to keep them in good condition. This saves time and money on maintenance costs, making stainless steel pipes a cost-effective option for many industries.

Stainless steel pipes are available in a wide range of sizes and shapes, making them highly customizable to suit specific industrial applications. Whether you need a small diameter Pipe for a residential plumbing project or a large diameter pipe for a commercial construction project, stainless steel pipes can be customized to meet your exact specifications. This flexibility in design makes stainless steel pipes a versatile option for a wide range of industrial applications.

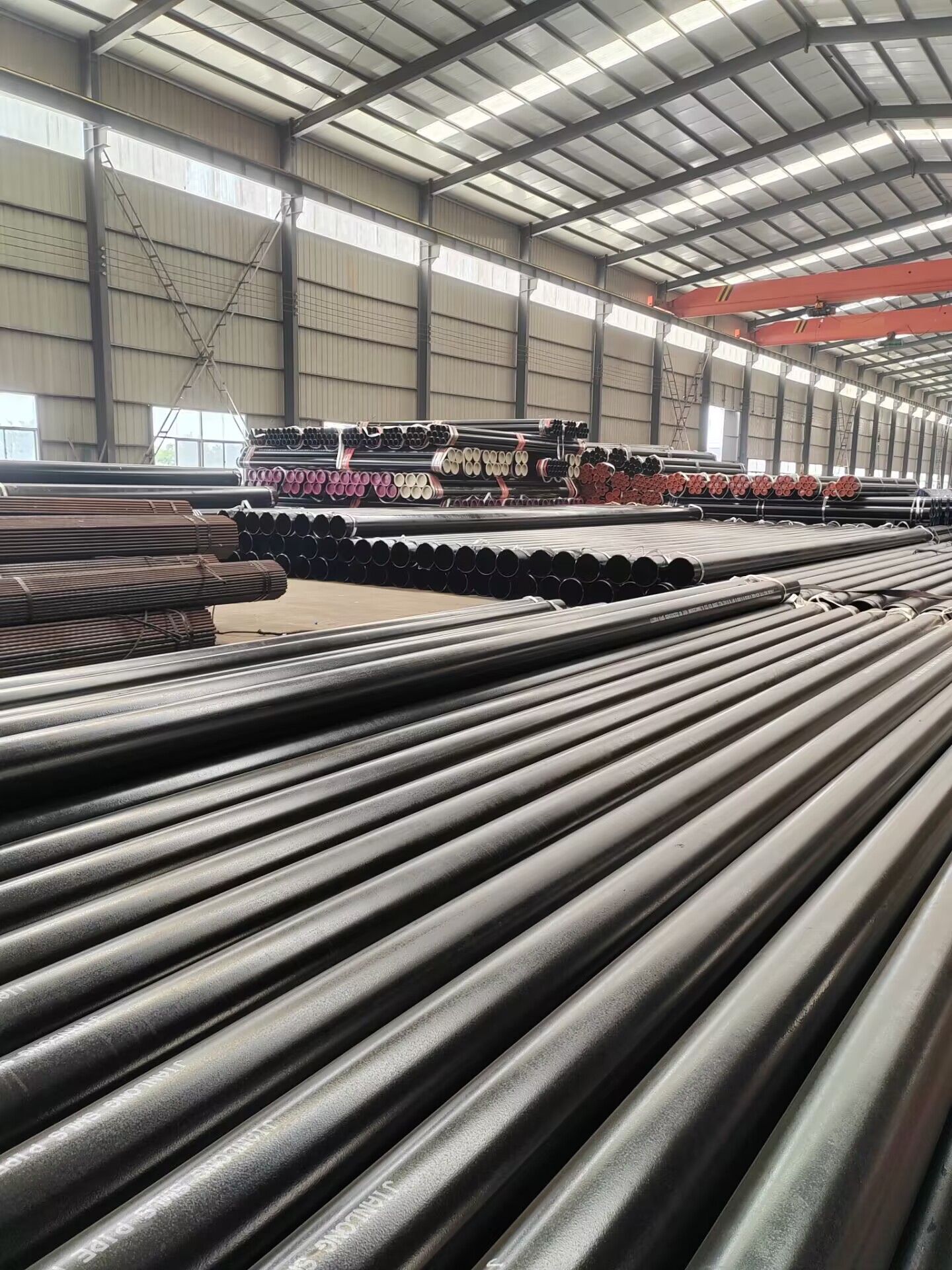

At Professional Factory, we specialize in manufacturing high-quality stainless steel pipes and tubes for various industrial applications. Our experienced team of engineers and technicians can customize stainless steel pipes to meet your specific requirements, ensuring that you get a product that is tailored to your needs. Whether you need Seamless steel pipes for a high-pressure application or welded steel tubes for a structural project, we have the expertise and resources to deliver a product that meets your expectations.

In conclusion, stainless steel pipes offer numerous benefits for industrial applications, including durability, corrosion resistance, high strength, and easy maintenance. These pipes are a cost-effective and reliable option for a wide range of industries, making them a popular choice for many applications. If you are looking for high-quality stainless steel pipes for your next project, consider Professional Factory for all your customization needs.

How to Choose the Right Grade of Stainless Steel for Your Customized Steel Pipes

Stainless steel pipes are a popular choice for a wide range of applications due to their durability, corrosion resistance, and aesthetic appeal. When it comes to choosing the right grade of stainless steel for your customized steel pipes, there are several factors to consider. In this article, we will discuss the different grades of stainless steel commonly used in the production of steel pipes and provide some tips on how to select the best grade for your specific needs.

One of the most important factors to consider when choosing a grade of stainless steel for your customized steel pipes is the level of corrosion resistance required for your application. Stainless steel is known for its resistance to corrosion, but different grades offer varying levels of protection against different types of corrosion. For example, grade 304 stainless steel is a popular choice for general-purpose applications due to its good corrosion resistance in a wide range of environments. On the other hand, grade 316 stainless steel offers even higher corrosion resistance, making it ideal for applications where the pipes will be exposed to harsh chemicals or saltwater.

Another important factor to consider when choosing a grade of stainless steel for your customized steel pipes is the temperature at which the pipes will be operating. Some grades of stainless steel are better suited for high-temperature applications, while others are more suitable for low-temperature environments. For example, grade 321 stainless steel is a good choice for applications where the pipes will be exposed to high temperatures, as it offers excellent resistance to oxidation and thermal fatigue. On the other hand, grade 410 stainless steel is a better choice for low-temperature applications, as it offers good strength and toughness at lower temperatures.

In addition to corrosion resistance and temperature resistance, it is also important to consider the Mechanical properties of the stainless steel grade you choose for your customized steel pipes. Different grades of stainless steel offer different levels of strength, Ductility, and toughness, so it is important to select a grade that meets the mechanical requirements of your application. For example, grade 430 stainless steel is a good choice for applications where high strength and Hardness are required, while grade 904 stainless steel offers excellent toughness and impact resistance.

When selecting a grade of stainless steel for your customized steel pipes, it is also important to consider the cost of the material. Some grades of stainless steel are more expensive than others, so it is important to balance the cost of the material with the performance requirements of your application. In some cases, it may be worth investing in a higher-grade stainless steel to ensure the long-term performance and durability of your customized steel pipes.

In conclusion, choosing the right grade of stainless steel for your customized steel pipes is a critical decision that can impact the performance and longevity of your pipes. By considering factors such as corrosion resistance, temperature resistance, mechanical properties, and cost, you can select a grade of stainless steel that meets the specific requirements of your application. Whether you need a grade 304, 316, 321, 410, or 904 stainless steel for your customized steel pipes, a professional factory can help you select the best grade and produce high-quality pipes that meet your needs.