Benefits of Using SS304, 316, and 316L Stainless steel pipes for Industrial Applications

Stainless steel pipes are a popular choice for industrial applications due to their durability, Corrosion resistance, and versatility. Among the various grades of stainless steel available, SS304, 316, and 316L are some of the most commonly used for piping systems. These grades offer unique benefits that make them ideal for a wide range of industrial applications.

One of the key benefits of using SS304 stainless steel pipes is their excellent corrosion resistance. SS304 contains a high percentage of chromium, which forms a protective oxide layer on the surface of the Pipe, preventing rust and corrosion. This makes SS304 pipes ideal for applications where they will be exposed to harsh chemicals, high temperatures, or corrosive environments.

In addition to their corrosion resistance, SS304 stainless steel pipes are also highly durable and have a long lifespan. This makes them a cost-effective choice for industrial applications where frequent maintenance or replacement of piping systems is not feasible. SS304 pipes are also easy to clean and maintain, making them a low-maintenance option for industrial facilities.

SS316 stainless steel pipes offer even greater corrosion resistance than SS304, thanks to the addition of molybdenum to the alloy. This makes SS316 pipes ideal for applications where they will be exposed to extreme temperatures, high levels of acidity, or saltwater environments. SS316 pipes are commonly used in industries such as chemical processing, food and beverage production, and marine engineering.

Another benefit of using SS316 stainless steel pipes is their high strength and toughness. SS316 pipes can withstand high pressure and temperature conditions without deforming or cracking, making them a reliable choice for demanding industrial applications. The high Tensile strength of SS316 pipes also makes them resistant to damage from impacts or vibrations, further extending their lifespan.

SS316L stainless steel pipes are a low-carbon version of SS316, offering similar corrosion resistance and strength properties with the added benefit of improved weldability. SS316L pipes are often used in applications where Welding is required, such as in the construction of piping systems or equipment. The low carbon content of SS316L pipes also makes them less susceptible to sensitization, a common issue in stainless steel welding that can lead to corrosion and cracking.

In addition to their corrosion resistance, durability, and strength, SS304, 316, and 316L stainless steel pipes also offer a polished mirror surface finish that enhances their aesthetic appeal. This makes them a popular choice for architectural and decorative applications where appearance is important, such as in building facades, interior design, or furniture manufacturing.

Overall, the benefits of using SS304, 316, and 316L stainless steel pipes for industrial applications are clear. These grades offer superior corrosion resistance, durability, strength, and aesthetic appeal, making them a versatile and reliable choice for a wide range of industries. Whether you need piping systems for chemical processing, food production, marine engineering, or architectural design, SS304, 316, and 316L stainless steel pipes are an excellent option to consider.

How to Choose the Right Stainless Steel Pipe for Your Project: Seamless Round Steel vs. Hollow Polished Mirror Surface Stainless Steel tube

Stainless steel pipes are a popular choice for a wide range of applications due to their durability, corrosion resistance, and aesthetic appeal. When it comes to selecting the right stainless steel pipe for your project, there are several factors to consider. Two common options are seamless round steel pipes and hollow polished mirror surface stainless steel tubes. In this article, we will discuss the differences between these two types of stainless steel pipes and provide guidance on how to choose the right one for your specific needs.

10mm stainless tube

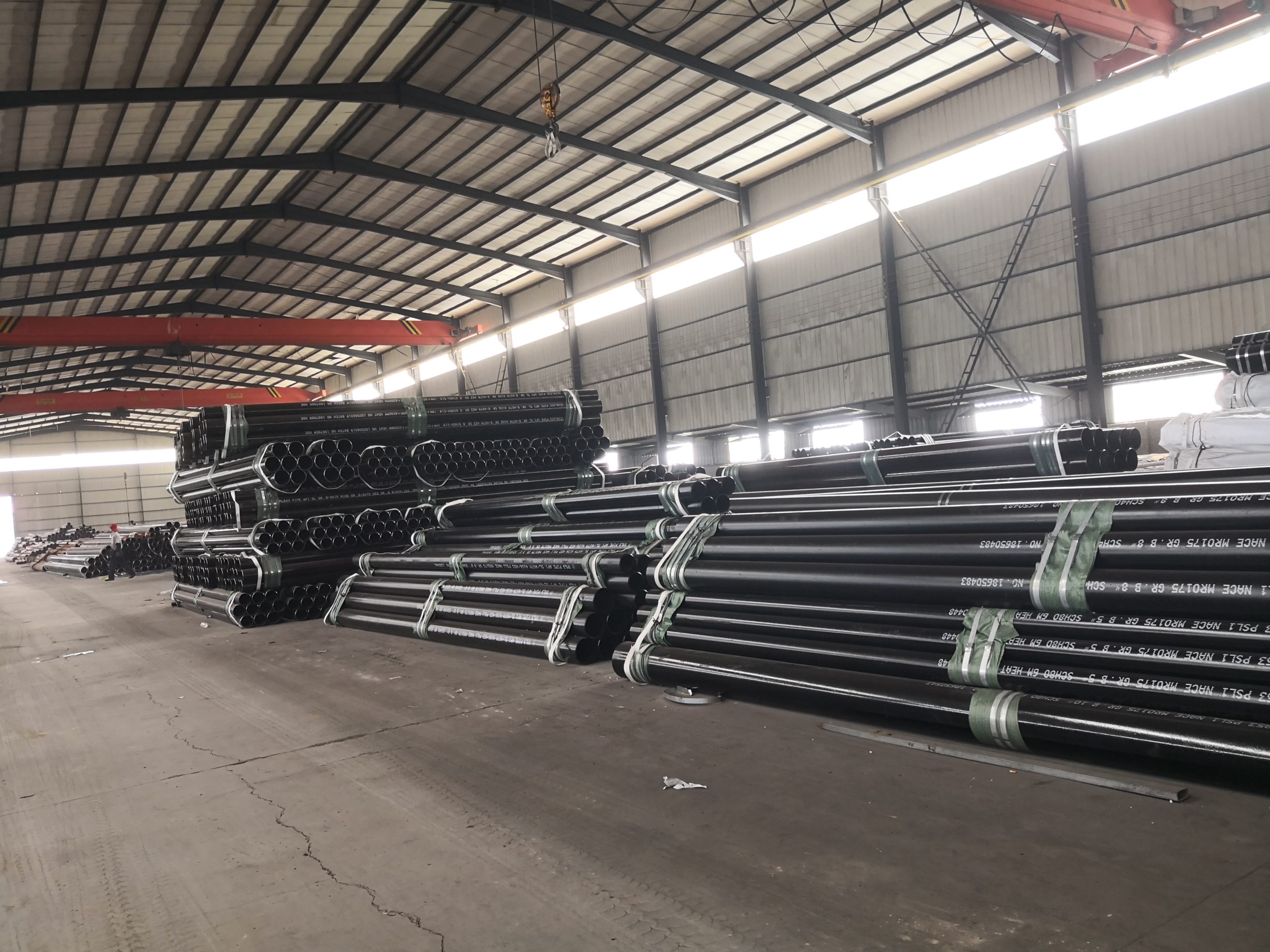

Seamless round steel pipes are made from solid billets of stainless steel that are heated and then pierced to create a seamless tube. This manufacturing process results in a pipe that is strong, durable, and resistant to corrosion. Seamless round steel pipes are commonly used in high-pressure applications, such as in the Oil and gas industry, where reliability and performance are critical. These pipes are also well-suited for applications that require a smooth interior surface, such as in the food and beverage industry.

On the other hand, hollow polished mirror surface stainless steel tubes are made from stainless steel sheets that are rolled and welded to form a tube. These tubes have a hollow interior and a polished mirror surface on the outside, giving them a sleek and modern appearance. Hollow polished mirror surface stainless steel tubes are often used in architectural and decorative applications, such as in railing systems, furniture, and interior design elements. These tubes are also popular in the automotive industry for exhaust systems and mufflers.

When choosing between seamless round steel pipes and hollow polished mirror surface stainless steel tubes, it is important to consider the specific requirements of your project. If you need a pipe that can withstand high pressures and temperatures, seamless round steel pipes may be the best option. These pipes are also a good choice for applications where a smooth interior surface is necessary, such as in the pharmaceutical or semiconductor industries.

On the other hand, if you are looking for a stainless steel pipe that offers both functionality and aesthetics, hollow polished mirror surface stainless steel tubes may be the right choice. These tubes are ideal for applications where appearance is important, such as in architectural or decorative projects. The polished mirror surface of these tubes can add a touch of elegance to any design, making them a popular choice for high-end projects.

In addition to considering the specific requirements of your project, it is also important to take into account the size, Wall thickness, and Material grade of the stainless steel pipe. Seamless round steel pipes are available in a wide range of sizes and wall thicknesses, making them suitable for a variety of applications. Hollow polished mirror surface stainless steel tubes are also available in different sizes and wall thicknesses, allowing you to choose the right option for your project.

In conclusion, when choosing a stainless steel pipe for your project, it is important to consider the specific requirements of your application, as well as the size, wall thickness, and material grade of the pipe. Seamless round steel pipes are a good choice for high-pressure applications that require a smooth interior surface, while hollow polished mirror surface stainless steel tubes are ideal for architectural and decorative projects. By carefully evaluating your needs and selecting the right type of stainless steel pipe, you can ensure the success of your project.