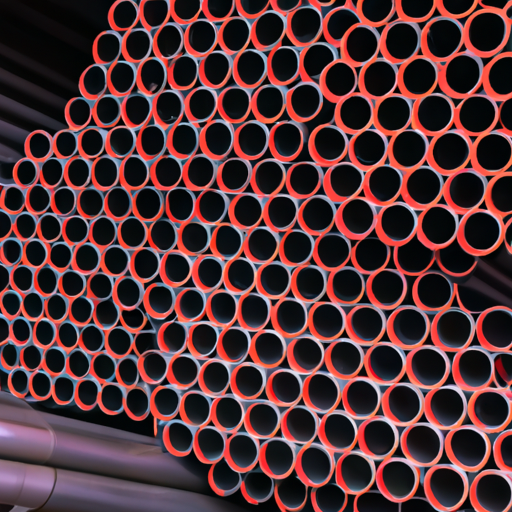

Benefits of Using Stainless steel Seamless Pipe in Industrial Applications

Stainless steel seamless pipe is a versatile and durable Material that is commonly used in various industrial applications. Its seamless construction offers numerous benefits that make it a preferred choice for many industries. In this article, we will explore the advantages of using stainless steel seamless pipe in industrial settings.

astm a 179One of the key benefits of stainless steel seamless pipe is its superior strength and Corrosion resistance. Stainless steel is known for its high Tensile strength, which makes it ideal for applications that require durability and reliability. Additionally, stainless steel is highly resistant to corrosion, making it suitable for use in harsh environments where exposure to moisture, chemicals, and other corrosive substances is common.

Another advantage of stainless steel seamless pipe is its smooth and uniform surface finish. Seamless pipes are manufactured without any seams or welds, which eliminates the risk of weak points that can lead to leaks or failures. The smooth surface of seamless pipe also reduces friction and turbulence, allowing for more efficient fluid flow in industrial processes.

Stainless steel seamless pipe is also known for its aesthetic appeal. The clean and polished appearance of stainless steel adds a professional and modern look to industrial equipment and structures. This can be particularly important in industries where aesthetics play a role in maintaining a positive image and reputation.

In addition to its strength, corrosion resistance, and aesthetic appeal, stainless steel seamless pipe is also easy to maintain and clean. Stainless steel is non-porous, which means that it does not harbor bacteria or other contaminants. This makes stainless steel seamless pipe a hygienic choice for industries such as food processing, pharmaceuticals, and healthcare.

Furthermore, stainless steel seamless pipe is highly recyclable and environmentally friendly. Stainless steel is a sustainable material that can be recycled and reused multiple times without losing its properties or quality. This makes stainless steel seamless pipe a cost-effective and eco-friendly option for industries that prioritize sustainability and environmental responsibility.

Stainless steel seamless pipe is also versatile and can be customized to meet specific requirements. Seamless pipes can be manufactured in a wide range of sizes, shapes, and grades to suit different industrial applications. Whether you need a small diameter pipe for a precision instrument or a large diameter pipe for a heavy-duty industrial process, stainless steel seamless pipe can be tailored to meet your needs.

In conclusion, stainless steel seamless pipe offers numerous benefits that make it an excellent choice for industrial applications. Its superior strength, corrosion resistance, smooth surface finish, aesthetic appeal, ease of maintenance, recyclability, and versatility make it a reliable and cost-effective material for a wide range of industries. If you are looking for a durable, reliable, and sustainable piping solution for your industrial needs, stainless steel seamless pipe is definitely worth considering.

How to Choose the Right Grade of Stainless Steel Seamless Pipe for Your Project

Stainless steel seamless pipes are a popular choice for a wide range of industrial applications due to their durability, corrosion resistance, and high strength. When selecting the right grade of stainless steel seamless pipe for your project, it is important to consider several factors to ensure optimal performance and longevity.

One of the first considerations when choosing a grade of stainless steel seamless pipe is the environment in which it will be used. Different grades of stainless steel offer varying levels of corrosion resistance, so it is essential to select a grade that can withstand the specific conditions of your project. For example, if your project will be exposed to harsh chemicals or high levels of moisture, a grade with a higher level of corrosion resistance, such as 316 stainless steel, may be more suitable.

Another important factor to consider when choosing a grade of stainless steel seamless pipe is the temperature at which it will be operating. Some grades of stainless steel are better suited for high-temperature applications, while others are more suitable for low-temperature environments. It is crucial to select a grade that can withstand the temperatures to which it will be exposed to ensure the longevity and performance of the pipe.

In addition to considering the environment and temperature of your project, it is also essential to think about the Mechanical properties required for your application. Different grades of stainless steel offer varying levels of strength, Ductility, and toughness, so it is crucial to select a grade that meets the specific mechanical requirements of your project. For example, if your project requires a high level of strength and durability, a grade with a higher tensile strength, such as 304 stainless steel, may be more suitable.

When selecting a grade of stainless steel seamless pipe, it is also important to consider the fabrication and Welding requirements of your project. Some grades of stainless steel are easier to weld and fabricate than others, so it is essential to choose a grade that can be easily manipulated to meet the specific requirements of your project. Additionally, some grades of stainless steel may require special welding procedures or post-weld treatments to ensure optimal performance, so it is crucial to consider these factors when selecting a grade.

Overall, choosing the right grade of stainless steel seamless pipe for your project is essential to ensure optimal performance, longevity, and cost-effectiveness. By considering factors such as the environment, temperature, mechanical properties, and fabrication requirements of your project, you can select a grade of stainless steel that meets your specific needs and requirements. Whether your project requires high corrosion resistance, strength, or weldability, there is a grade of stainless steel seamless pipe that is suitable for your application.