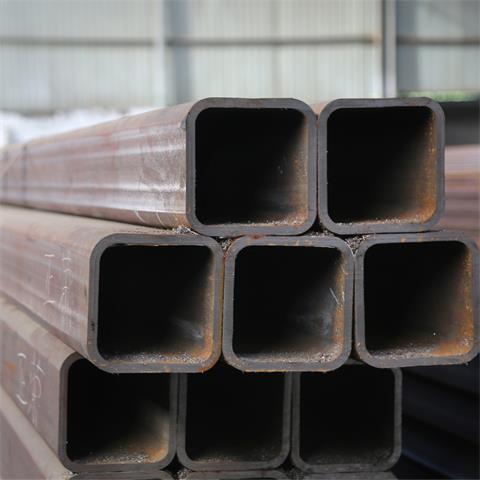

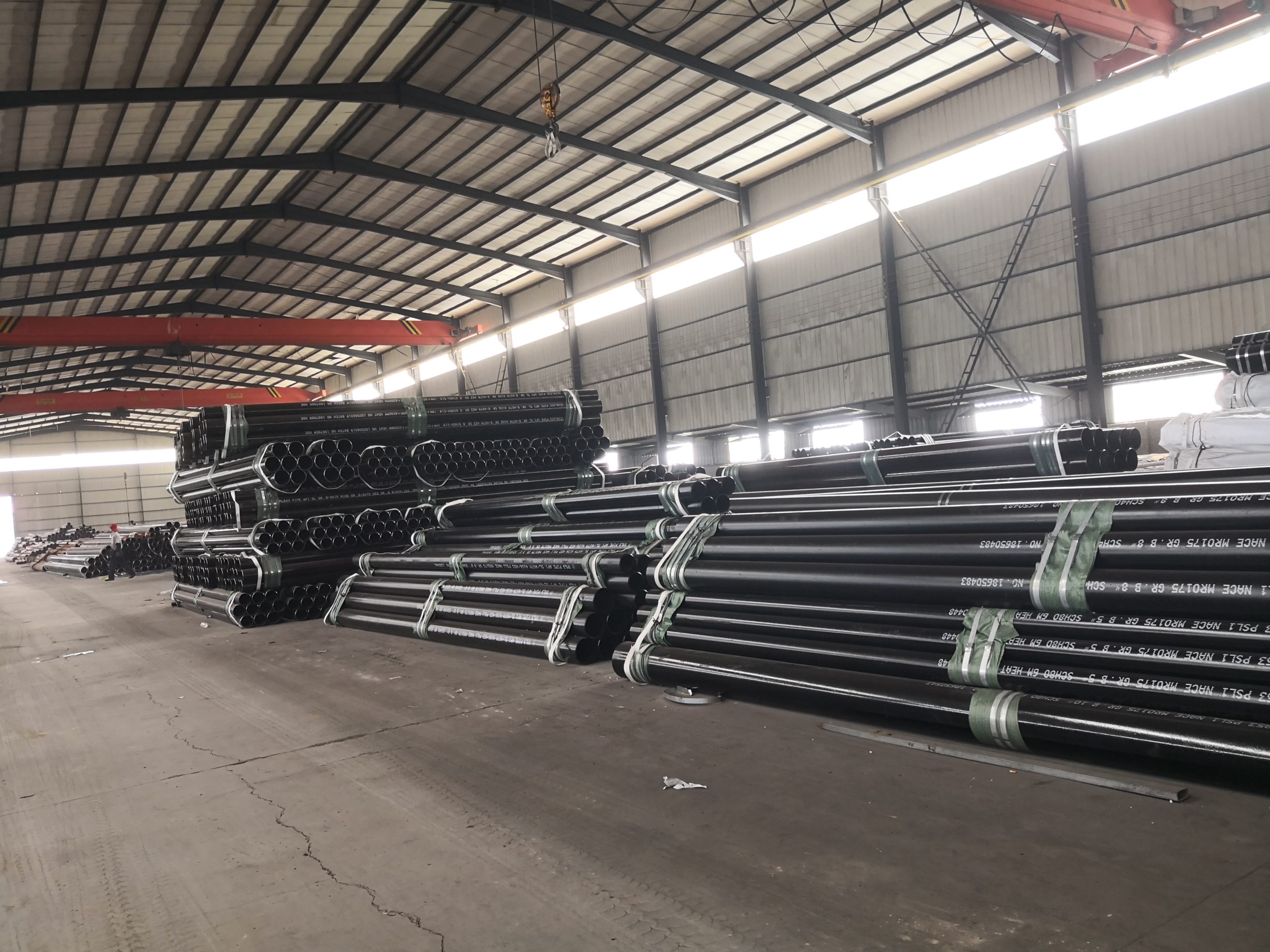

steel pipes are steels with a hollow cross-section whose Length is much greater than the diameter or circumference. According to the cross-sectional shape, it is divided into circular, square, rectangular and special-shaped steel pipes; according to the Material, it is divided into carbon structural steel pipes, low-alloy structural steel pipes, Alloy steel pipes and composite steel pipes; Steel pipes for thermal equipment, petrochemical industry, machinery manufacturing, geological drilling, high-pressure equipment, etc.; according to the production process, they are divided into Seamless steel pipes and welded steel pipes, of which seamless steel pipes are divided into hot-rolled and cold-rolled (drawn) Two types, welded steel pipes are divided into straight seam welded steel pipes and spiral seam welded steel pipes.

Steel pipes are not only used for conveying fluids and powdered solids, exchanging thermal energy, making machine parts and containers, but also an economical steel. Using steel pipes to make building structure grids, pillars and mechanical supports can reduce Weight, save 20-40% of metal, and realize factory-based mechanized construction. Using steel pipes to manufacture highway bridges can not only save steel and simplify construction, but also greatly reduce the area of protective coating, saving investment and maintenance costs.