Benefits of Using Low Carbon steel Pipe Q235B/Q195/Ss400 for Industrial Applications

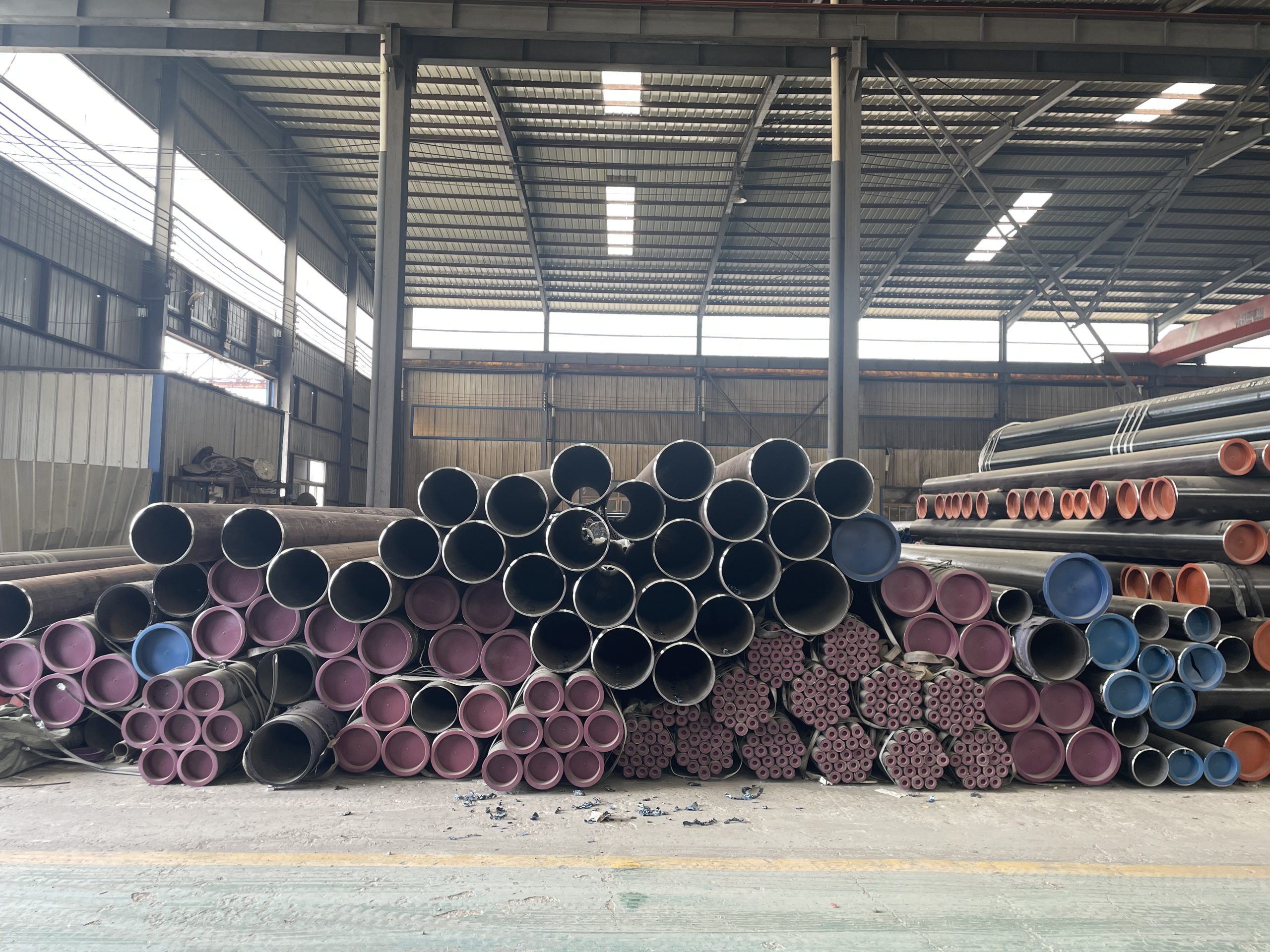

Low carbon steel is a popular Material choice for a wide range of industrial applications due to its versatility, durability, and cost-effectiveness. One of the most commonly used types of low carbon steel is Q235B/Q195/Ss400, which is known for its high quality and excellent performance in various environments. In this article, we will explore the benefits of using low carbon steel pipe Q235B/Q195/Ss400 for industrial applications, specifically focusing on Seamless carbon steel pipe, hollow round pipe, spiral pipe, and welded pipe.

One of the key advantages of using low carbon steel pipe Q235B/Q195/Ss400 is its high strength-to-Weight ratio. This means that the material is strong and durable, yet lightweight and easy to work with. This makes it an ideal choice for applications where strength and durability are essential, such as in the construction of buildings, bridges, and other structures.

Additionally, low carbon steel pipe Q235B/Q195/Ss400 is known for its excellent weldability. This means that it can be easily welded and formed into various shapes and sizes without compromising its structural integrity. This makes it a versatile material that can be used in a wide range of applications, from piping and Tubing to structural components and machinery parts.

Another benefit of using low carbon steel pipe Q235B/Q195/Ss400 is its Corrosion resistance. The material is highly resistant to rust and corrosion, making it ideal for use in environments where exposure to moisture, chemicals, or other corrosive substances is a concern. This makes it a reliable and long-lasting material choice for industrial applications that require durability and longevity.

In addition to its strength, weldability, and corrosion resistance, low carbon steel pipe Q235B/Q195/Ss400 is also cost-effective. The material is readily available and relatively inexpensive compared to other types of steel, making it a cost-effective option for industrial applications that require high-quality materials at a reasonable price.

Furthermore, low carbon steel pipe Q235B/Q195/Ss400 is environmentally friendly. The material is recyclable and can be reused multiple times without losing its structural integrity or performance. This makes it a sustainable choice for industrial applications that prioritize environmental responsibility and sustainability.

Overall, low carbon steel pipe Q235B/Q195/Ss400 offers a wide range of benefits for industrial applications. From its high strength-to-weight ratio and excellent weldability to its corrosion resistance and cost-effectiveness, this material is a versatile and reliable option for a variety of projects. Whether you are building a new structure, repairing existing equipment, or fabricating machinery parts, low carbon steel pipe Q235B/Q195/Ss400 is a smart choice that will deliver exceptional performance and durability.

A Comprehensive Guide to Choosing Between Seamless, Hollow Round, Spiral, and Welded Carbon Steel Pipes

When it comes to choosing the right carbon steel pipe for your industrial needs, there are several options to consider. The Factory offers a range of high-quality low carbon steel pipes, including Q235B, Q195, and SS400 seamless carbon steel pipes, as well as hollow round, spiral, and welded pipes. Each type of pipe has its own unique characteristics and advantages, so it’s important to understand the differences between them in order to make an informed decision.

Seamless carbon steel pipes are made by piercing a solid billet of steel to create a hollow tube. This process results in a pipe with no seams or welds, making it stronger and more reliable than welded pipes. Seamless pipes are ideal for high-pressure applications and are resistant to corrosion, making them a popular choice for industries such as Oil and gas, petrochemical, and power generation.

Hollow round carbon steel pipes are similar to seamless pipes but have a hollow center, which reduces weight and increases strength. These pipes are commonly used in structural applications, such as building construction and infrastructure projects. Hollow round pipes are versatile and can be easily welded or machined to meet specific requirements.

steel exhaust pipeSpiral carbon steel pipes are made by forming a strip of steel into a spiral shape and Welding the edges together. This process creates a pipe with a helical seam, which provides added strength and flexibility. Spiral pipes are commonly used in underground piping systems, as well as in the construction of bridges and tunnels. The spiral design helps to distribute stress evenly along the Length of the pipe, making it ideal for high-stress applications.

Welded carbon steel pipes are made by welding together two or more pieces of steel to create a seamless joint. Welded pipes are cost-effective and easy to produce, making them a popular choice for a wide range of applications. However, welded pipes are not as strong or durable as seamless pipes and may be more prone to corrosion over time. Welded pipes are commonly used in plumbing, heating, and ventilation systems, as well as in the automotive and manufacturing industries.

When choosing between seamless, hollow round, spiral, and welded carbon steel pipes, there are several factors to consider. The type of application, the level of pressure and temperature, and the desired strength and durability of the pipe all play a role in determining the best option for your needs. It’s important to consult with a knowledgeable supplier, such as The Factory, to ensure that you choose the right type of pipe for your specific requirements.

In conclusion, The Factory offers a range of high-quality low carbon steel pipes, including Q235B, Q195, and SS400 seamless carbon steel pipes, as well as hollow round, spiral, and welded pipes. Each type of pipe has its own unique characteristics and advantages, so it’s important to carefully consider your needs before making a decision. By understanding the differences between seamless, hollow round, spiral, and welded carbon steel pipes, you can choose the best option for your industrial applications.