Corrosion susceptibility

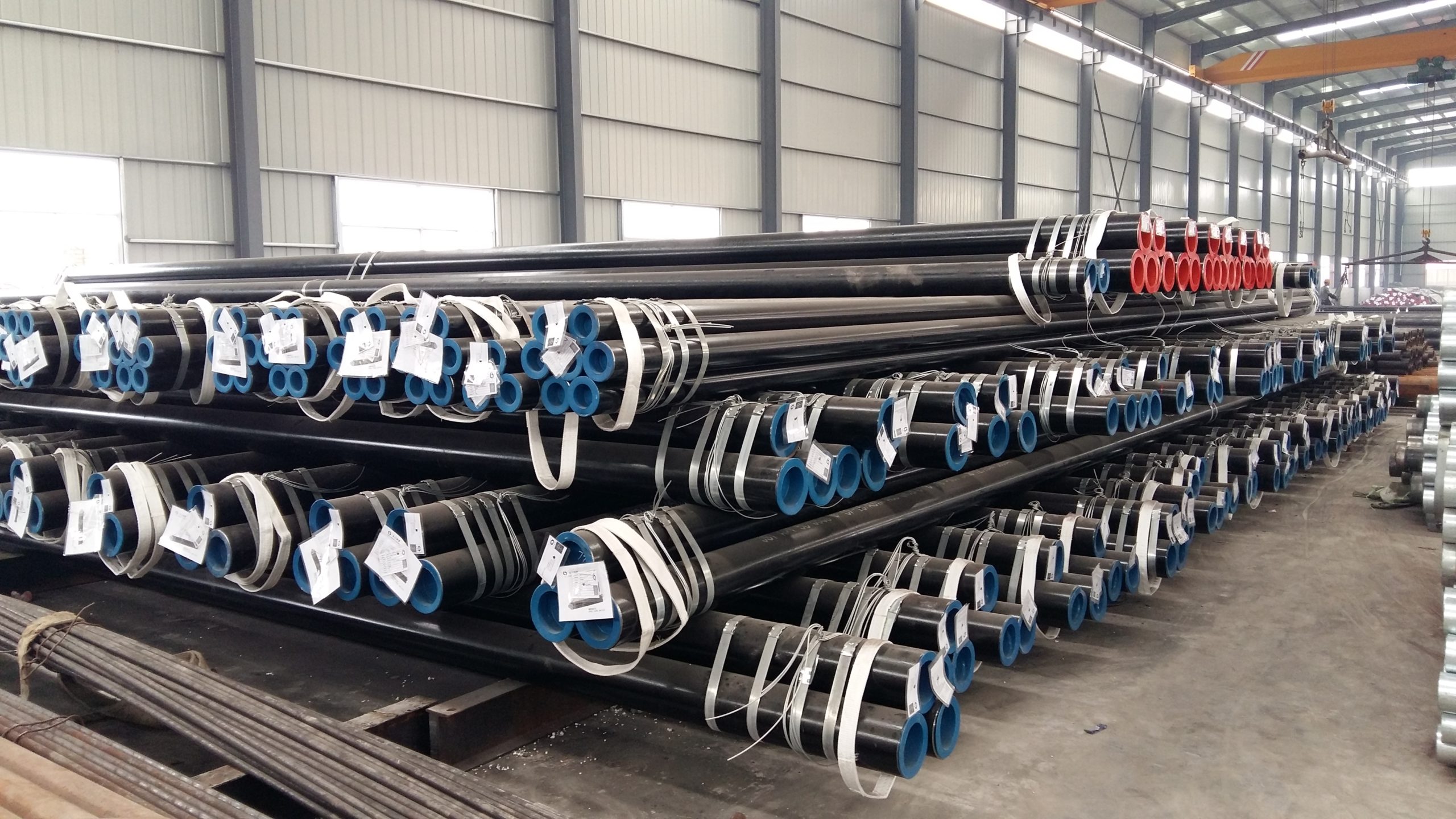

Seamless pipes are widely used in various industries due to their high strength, durability, and ability to withstand high pressure and temperature. However, like any other Material, seamless pipes also have their disadvantages. One of the major drawbacks of seamless pipes is their susceptibility to corrosion.

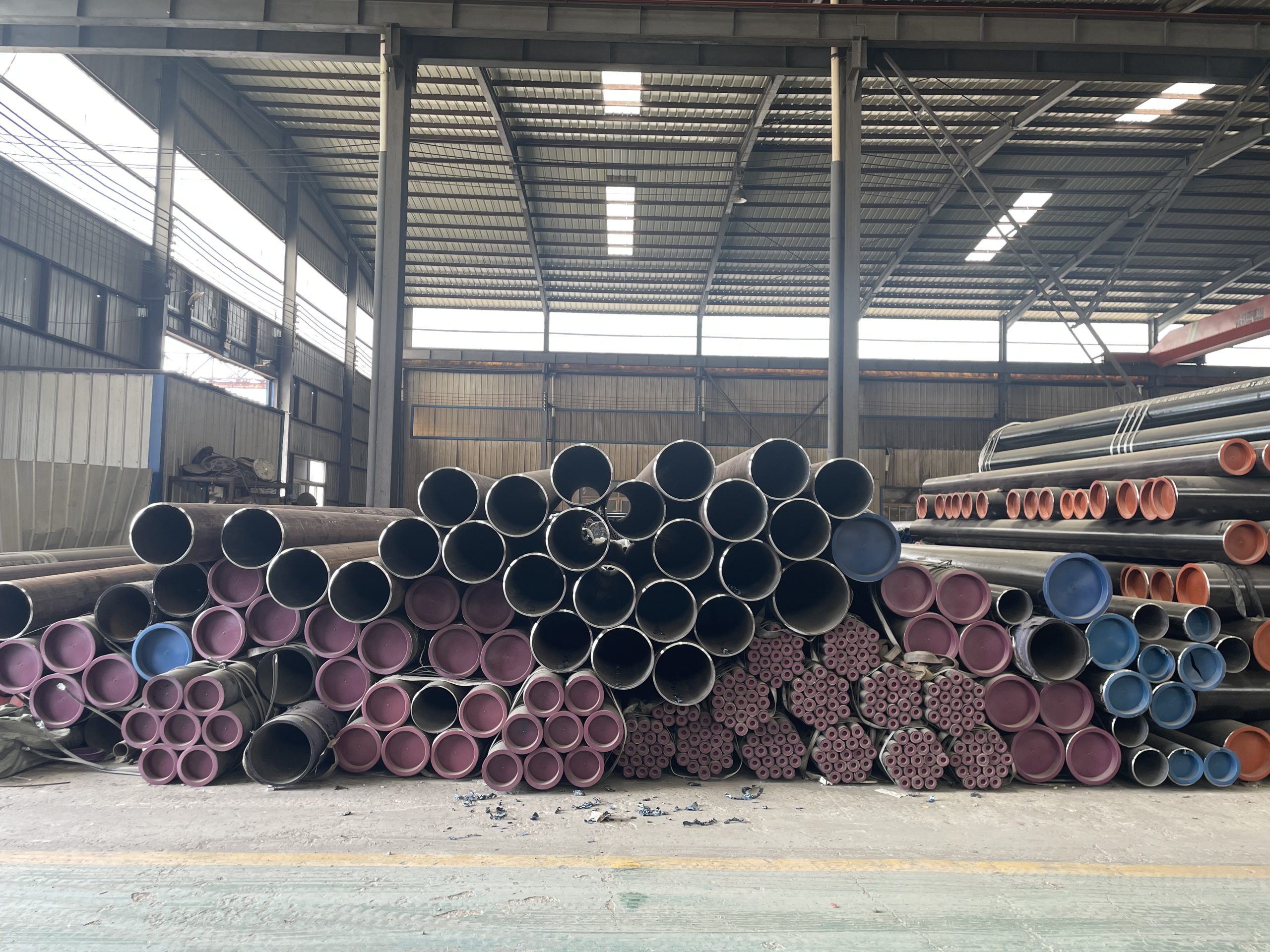

Corrosion is a natural process that occurs when metal is exposed to oxygen and moisture, leading to the formation of rust or other forms of corrosion. Seamless pipes are made of metal, typically steel, which is prone to corrosion when exposed to harsh environmental conditions. This can lead to a decrease in the structural integrity of the Pipe, ultimately compromising its performance and lifespan.

One of the main reasons why seamless pipes are more susceptible to corrosion compared to welded pipes is the manufacturing process. Seamless pipes are made by piercing a solid billet of metal to create a hollow tube, while welded pipes are made by Welding together two pieces of metal. The seamless manufacturing process leaves the pipe with a smooth, uniform surface, making it more vulnerable to corrosion compared to the rougher surface of welded pipes.

4130 tubingIn addition, seamless pipes are often used in applications where they are exposed to corrosive substances, such as chemicals or saltwater. These substances can accelerate the corrosion process, leading to premature failure of the pipe. Furthermore, seamless pipes are often used in high-temperature and high-pressure applications, which can also contribute to corrosion.

Another factor that contributes to the corrosion susceptibility of seamless pipes is the lack of protective coatings. Welded pipes can be coated with various materials to protect them from corrosion, such as epoxy or zinc coatings. However, seamless pipes are typically not coated, leaving them more vulnerable to corrosion.

To mitigate the risk of corrosion in seamless pipes, various preventive measures can be taken. One common method is to apply a corrosion-resistant coating to the pipe surface. This can help protect the pipe from the effects of corrosion and extend its lifespan. Additionally, regular inspection and maintenance of seamless pipes can help identify any signs of corrosion early on, allowing for timely repairs or replacements.

Despite their susceptibility to corrosion, seamless pipes continue to be a popular choice in many industries due to their numerous advantages. However, it is important for users to be aware of the potential drawbacks of seamless pipes and take appropriate measures to prevent corrosion. By understanding the factors that contribute to corrosion in seamless pipes and implementing preventive measures, users can ensure the longevity and performance of their seamless pipe systems.