Benefits of Using Seamless steel Pipes for Hydraulic Systems

Seamless steel pipes are a crucial component in hydraulic systems, offering a range of benefits that make them a popular choice for various applications. These pipes are known for their durability, strength, and resistance to corrosion, making them ideal for use in demanding environments where reliability is essential.

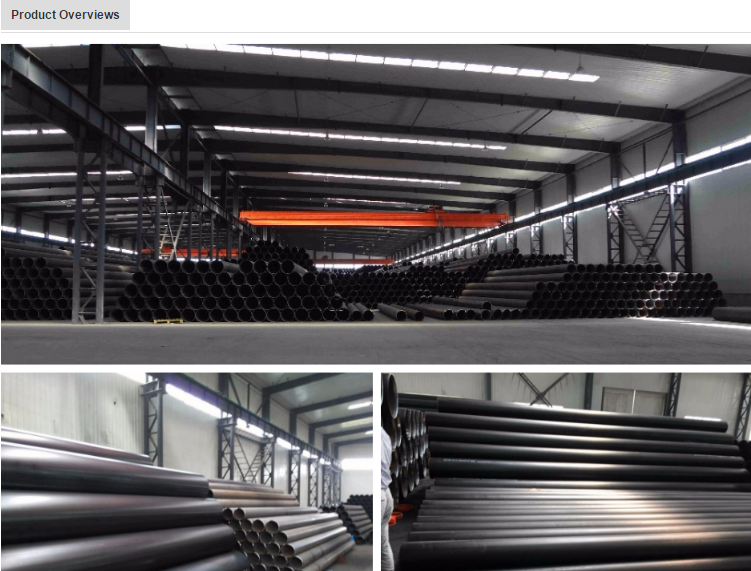

One of the key advantages of seamless steel pipes is their uniformity and consistency in terms of thickness and diameter. Unlike welded pipes, which are made by Welding together multiple pieces of steel, seamless pipes are made from a single piece of steel that is heated and stretched to form a seamless tube. This manufacturing process results in a Pipe that is free from seams or joints, reducing the risk of leaks and ensuring a smooth flow of fluids through the system.

The seamless construction of these pipes also makes them stronger and more resistant to pressure and stress. This is particularly important in hydraulic systems, where pipes are subjected to high levels of pressure and must be able to withstand the forces generated by the fluid flowing through them. Seamless steel pipes are able to handle these pressures without the risk of cracking or breaking, ensuring the safety and reliability of the system.

In addition to their strength and durability, seamless steel pipes are also highly resistant to corrosion. This is due to the fact that the seamless construction eliminates the need for welding, which can create weak points in the pipe where corrosion can occur. The smooth surface of seamless pipes also makes them less susceptible to the buildup of rust and other corrosive materials, ensuring a longer lifespan and lower maintenance costs for the hydraulic system.

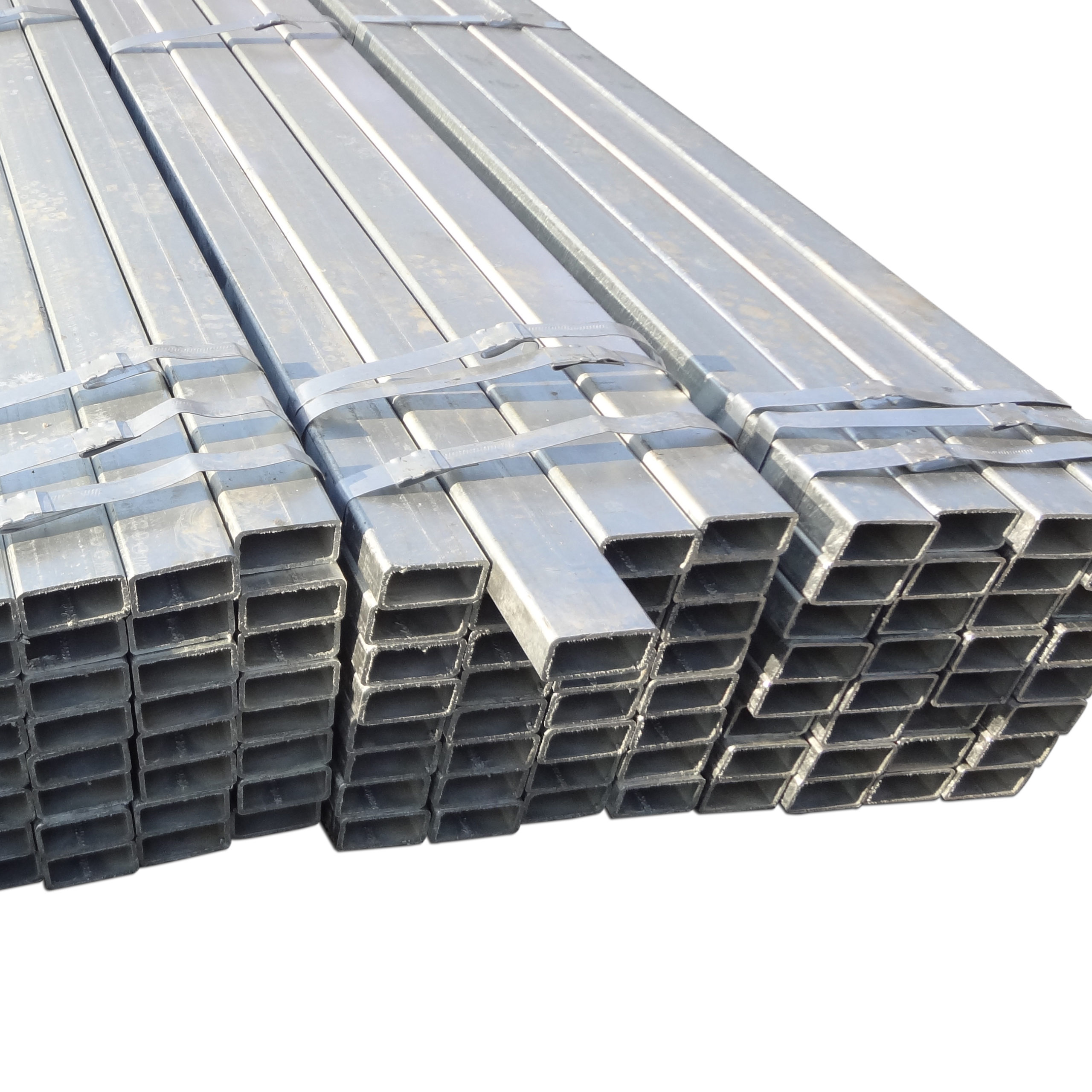

galvanized steel Tubing suppliers near me

Another benefit of using seamless steel pipes in hydraulic systems is their precision and accuracy. These pipes are manufactured to tight tolerances, ensuring a perfect fit and seal when connecting different components of the system. This precision is essential in hydraulic systems, where even the smallest leak or misalignment can lead to a loss of pressure and efficiency. Seamless steel pipes provide a reliable and consistent connection, ensuring the smooth operation of the system.

Seamless steel pipes are also available in a variety of sizes and dimensions to suit different applications. Whether you need a small diameter pipe for a compact system or a larger diameter pipe for a high-flow system, there is a Seamless steel pipe available to meet your needs. This versatility makes seamless steel pipes a versatile and cost-effective choice for a wide range of hydraulic applications.

In conclusion, seamless steel pipes offer a range of benefits that make them an ideal choice for hydraulic systems. Their strength, durability, resistance to corrosion, precision, and versatility make them a reliable and efficient option for a variety of applications. Whether you are building a new hydraulic system or upgrading an existing one, seamless steel pipes are a smart choice that will ensure the safety, reliability, and efficiency of your system.

How to Choose the Right Size and Type of Seamless Steel Pipe for Your Hydraulic Applications

When it comes to choosing the right size and type of seamless steel pipe for your hydraulic applications, there are several factors to consider. Seamless steel pipes are commonly used in hydraulic systems due to their durability, strength, and ability to withstand high pressure. However, selecting the correct size and type of seamless steel pipe is crucial to ensure optimal performance and safety in your hydraulic system.

One of the first things to consider when choosing a seamless steel pipe for your hydraulic applications is the size of the pipe. The size of the pipe is typically measured by its outer diameter (OD) and Wall thickness. The outer diameter of the pipe is important as it determines the flow rate of the hydraulic fluid through the system. A larger outer diameter will allow for a higher flow rate, while a smaller outer diameter will result in a lower flow rate. The wall thickness of the pipe is also important as it affects the strength and durability of the pipe. Thicker walls provide greater strength and durability, making them suitable for high-pressure applications.

In addition to size, it is also important to consider the type of seamless steel pipe for your hydraulic applications. There are several types of seamless steel pipes available, including mild steel pipes, hydraulic seamless steel tubes, precision tubes, galvanized hydraulic pipes, and explosion-proof tubes. Each type of pipe has its own unique properties and advantages, so it is important to choose the right type based on your specific application requirements.

Mild steel pipes are commonly used in hydraulic systems due to their affordability and versatility. They are suitable for low to medium pressure applications and are available in a variety of sizes and wall thicknesses. Hydraulic seamless steel tubes are designed for high-pressure applications and are known for their strength and durability. Precision tubes are manufactured to tight tolerances, making them ideal for applications that require high precision and accuracy. Galvanized hydraulic pipes are coated with a layer of zinc to protect against corrosion, making them suitable for outdoor and corrosive environments. Explosion-proof tubes are designed to withstand high temperatures and pressures, making them ideal for hazardous environments.

When selecting the right size and type of seamless steel pipe for your hydraulic applications, it is important to consider the specific requirements of your system. Factors such as operating pressure, flow rate, temperature, and environment should all be taken into account when choosing a seamless steel pipe. It is also important to consult with a professional engineer or supplier to ensure that you are selecting the right pipe for your specific application.

In conclusion, choosing the right size and type of seamless steel pipe for your hydraulic applications is crucial to ensure optimal performance and safety in your system. By considering factors such as size, type, and specific requirements, you can select a seamless steel pipe that meets your needs and provides reliable operation. Consulting with a professional engineer or supplier can help you make an informed decision and ensure that you are selecting the best pipe for your hydraulic applications.