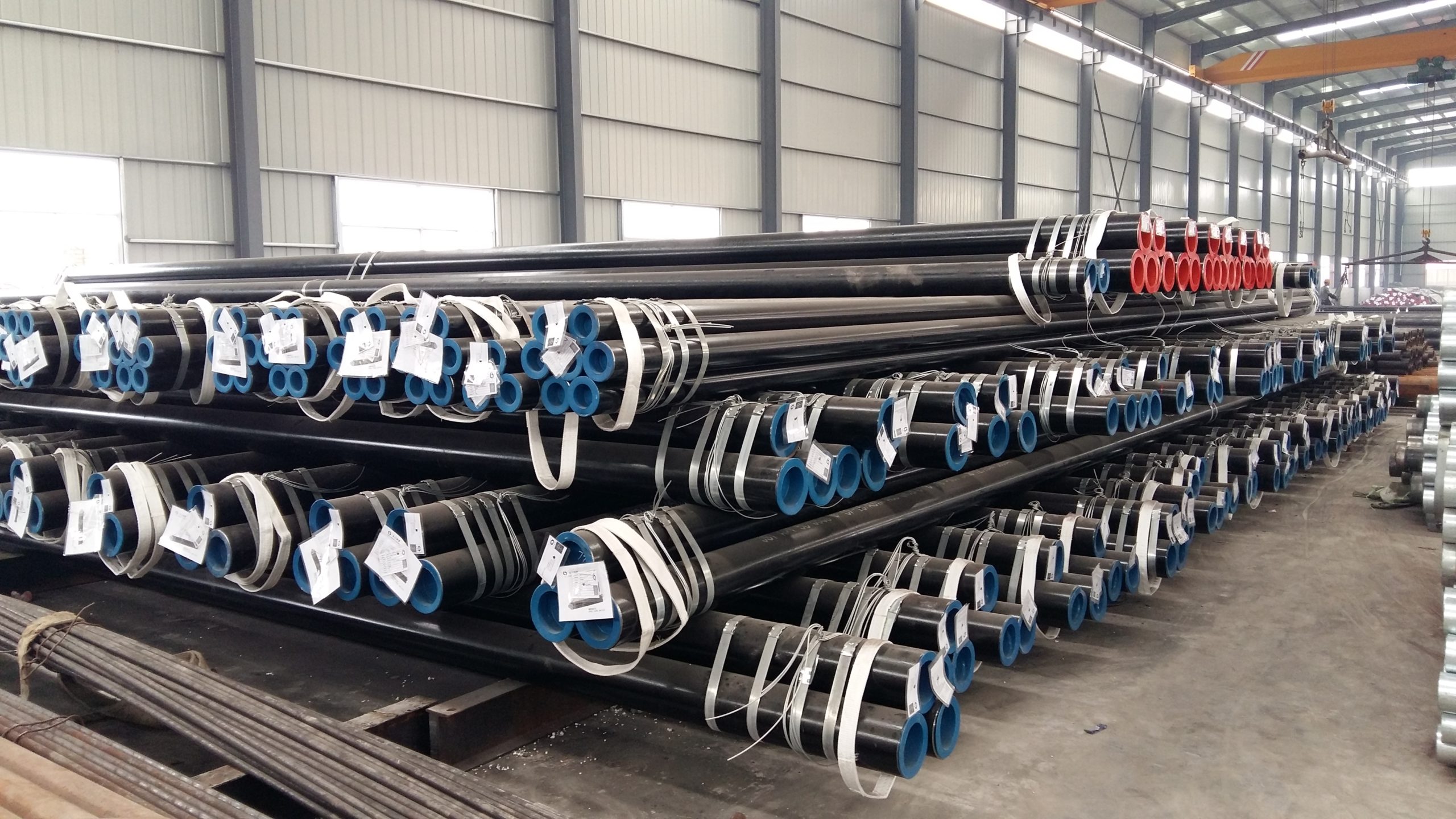

Benefits of Using steel Seamless Pipes in the Oil and Gas Industry

Steel seamless pipes are a crucial component in various industries, with one of the most prominent being the oil and gas industry. These pipes are known for their durability, strength, and resistance to corrosion, making them an ideal choice for transporting fluids and gases under high pressure and temperature conditions. In this article, we will explore the common uses and applications of steel seamless pipes in the oil and gas industry.

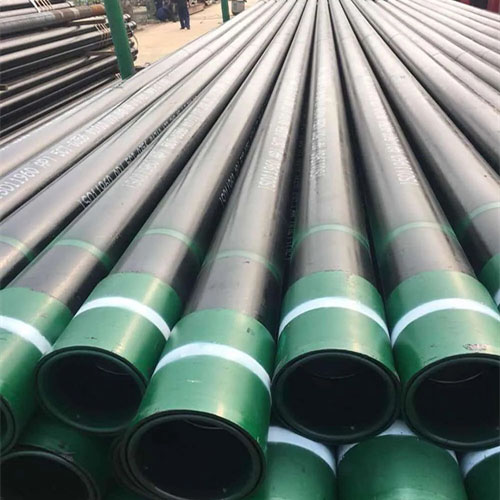

One of the key benefits of using steel seamless pipes in the oil and gas industry is their ability to withstand high pressure and temperature conditions. These pipes are manufactured without any seams, which eliminates the weak points that are often found in welded pipes. As a result, steel seamless pipes are able to handle extreme pressure and temperature fluctuations without the risk of leakage or failure.

In addition to their strength and durability, steel seamless pipes are also highly resistant to corrosion. This is particularly important in the oil and gas industry, where pipes are constantly exposed to corrosive substances such as oil, gas, and saltwater. By using steel seamless pipes, companies can ensure that their pipelines remain in optimal condition for longer periods of time, reducing the need for costly repairs and replacements.

Steel seamless pipes are also known for their versatility and flexibility. These pipes can be easily bent and shaped to fit the specific requirements of a project, making them ideal for use in complex pipeline systems. Whether it’s a straight line or a curved path, steel seamless pipes can be customized to meet the unique needs of each project, ensuring a seamless and efficient flow of fluids and gases.

Another advantage of using steel seamless pipes in the oil and gas industry is their cost-effectiveness. While the initial cost of steel seamless pipes may be higher than that of welded pipes, their long-term durability and resistance to corrosion can result in significant cost savings over time. By investing in high-quality steel seamless pipes, companies can avoid the need for frequent maintenance and repairs, ultimately reducing operational costs and increasing profitability.

Furthermore, steel seamless pipes are environmentally friendly. These pipes are 100% recyclable, making them a sustainable choice for companies looking to reduce their carbon footprint. By using steel seamless pipes in their operations, companies can contribute to a more sustainable future while also benefiting from the superior performance and longevity of these pipes.

In conclusion, steel seamless pipes are an essential component in the oil and gas industry due to their strength, durability, resistance to corrosion, versatility, and cost-effectiveness. By investing in high-quality steel seamless pipes, companies can ensure the efficient and reliable transportation of fluids and gases, ultimately leading to increased productivity and profitability. Additionally, the environmentally friendly nature of steel seamless pipes makes them a sustainable choice for companies looking to reduce their impact on the environment. Overall, steel seamless pipes are a valuable asset in the oil and gas industry, providing a wide range of benefits that contribute to the success and sustainability of companies in this sector.

How Steel Seamless Pipes are Utilized in Construction Projects

Steel seamless pipes are a crucial component in various construction projects due to their durability, strength, and versatility. These pipes are made from solid steel billets that are heated and molded into a cylindrical shape without any seams. This seamless construction provides a higher level of strength and reliability compared to welded pipes, making them ideal for a wide range of applications in the construction industry.

One common use of steel seamless pipes in construction projects is for transporting fluids and gases. These pipes are commonly used in plumbing systems, water treatment plants, and oil and gas pipelines due to their ability to withstand high pressure and temperature. The seamless construction of these pipes ensures a leak-proof and efficient flow of fluids, making them a reliable choice for critical infrastructure projects.

Steel seamless pipes are also widely used in structural applications in construction projects. These pipes are often used as columns, beams, and support structures in buildings, bridges, and other structures due to their high strength-to-Weight ratio. The seamless construction of these pipes allows for greater load-bearing capacity and structural integrity, making them a preferred choice for supporting heavy loads and withstanding external forces.

In addition to their structural and fluid transportation applications, steel seamless pipes are also used in the construction of mechanical systems and equipment. These pipes are commonly used in manufacturing plants, power plants, and industrial facilities for conveying materials, steam, and other substances. The seamless construction of these pipes ensures a smooth and efficient flow of materials, making them essential for the operation of various mechanical systems and equipment.

Another common application of steel seamless pipes in construction projects is for underground utilities and infrastructure. These pipes are often used for sewer lines, water mains, and stormwater drainage systems due to their Corrosion resistance and longevity. The seamless construction of these pipes ensures a durable and reliable solution for underground utilities, reducing the risk of leaks, breaks, and maintenance issues over time.

sa213 tp316l

Steel seamless pipes are also utilized in the construction of offshore structures and marine facilities. These pipes are commonly used in oil rigs, offshore platforms, and marine vessels due to their ability to withstand harsh environmental conditions, such as saltwater corrosion and high pressure. The seamless construction of these pipes ensures a reliable and long-lasting solution for offshore applications, where safety and durability are paramount.

In conclusion, steel seamless pipes are a versatile and essential component in various construction projects due to their strength, durability, and reliability. From transporting fluids and gases to supporting structures and mechanical systems, these pipes play a crucial role in the construction industry. Whether used in plumbing systems, structural applications, underground utilities, or offshore structures, steel seamless pipes provide a dependable and efficient solution for a wide range of construction applications.