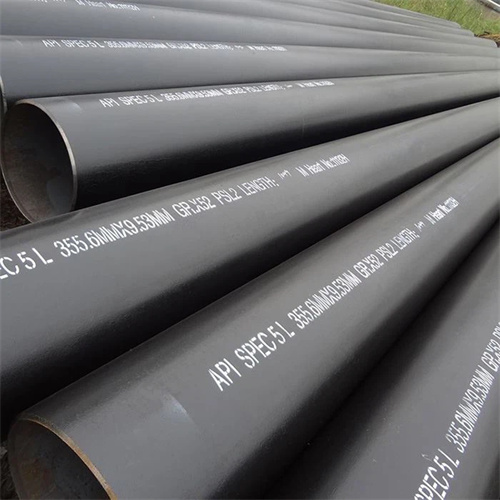

Benefits of Using Large Diameter Seamless Pipe in Industrial Applications

Large diameter seamless pipe is a crucial component in various industrial applications due to its numerous benefits. These pipes are known for their durability, strength, and resistance to corrosion, making them ideal for use in demanding environments. In this article, we will explore the advantages of using large diameter seamless pipe in industrial settings.

One of the primary benefits of large diameter seamless pipe is its superior strength. These pipes are manufactured using a seamless process, which eliminates the weak points that are often found in welded pipes. As a result, seamless pipes can withstand higher pressure and temperature levels, making them suitable for use in critical applications where safety is paramount.

In addition to their strength, large diameter seamless pipes are also highly resistant to corrosion. The seamless manufacturing process ensures that there are no seams or joints where corrosion can occur, making these pipes ideal for use in corrosive environments such as chemical plants, refineries, and offshore drilling platforms. This Corrosion resistance helps to extend the lifespan of the pipes, reducing the need for frequent maintenance and replacement.

large steel tubeAnother advantage of large diameter seamless pipe is its smooth interior surface. The absence of seams and joints in seamless pipes results in a smooth bore that allows for efficient fluid flow. This smooth surface reduces friction and turbulence, which can help to improve the overall efficiency of industrial processes that rely on the transportation of liquids or gases through pipelines.

Furthermore, large diameter seamless pipes are known for their uniformity and consistency in terms of Wall thickness. This uniformity ensures that the pipes can withstand high levels of stress and pressure without deforming or failing. In contrast, welded pipes may have variations in wall thickness due to the Welding process, which can lead to weak points and potential failure under stress.

Large diameter seamless pipes are also easier to install and maintain compared to welded pipes. The seamless design eliminates the need for welding, which can be a time-consuming and costly process. Additionally, the smooth interior surface of seamless pipes makes them easier to clean and inspect, reducing the risk of contamination and ensuring the integrity of the pipeline system.

In conclusion, large diameter seamless pipe offers a range of benefits that make it an ideal choice for industrial applications. From its superior strength and corrosion resistance to its smooth interior surface and uniform wall thickness, seamless pipes provide a reliable and efficient solution for transporting fluids and gases in demanding environments. By choosing large diameter seamless pipe for your industrial needs, you can ensure the safety, efficiency, and longevity of your pipeline system.