Benefits of Using ERW Cold Rolled Stainless steel Pipe for Industrial Applications

Stainless steel is a versatile Material that is widely used in various industrial applications due to its durability, Corrosion resistance, and aesthetic appeal. When it comes to choosing the right type of stainless steel pipe for your project, ERW cold rolled stainless steel pipe is a popular choice for many reasons.

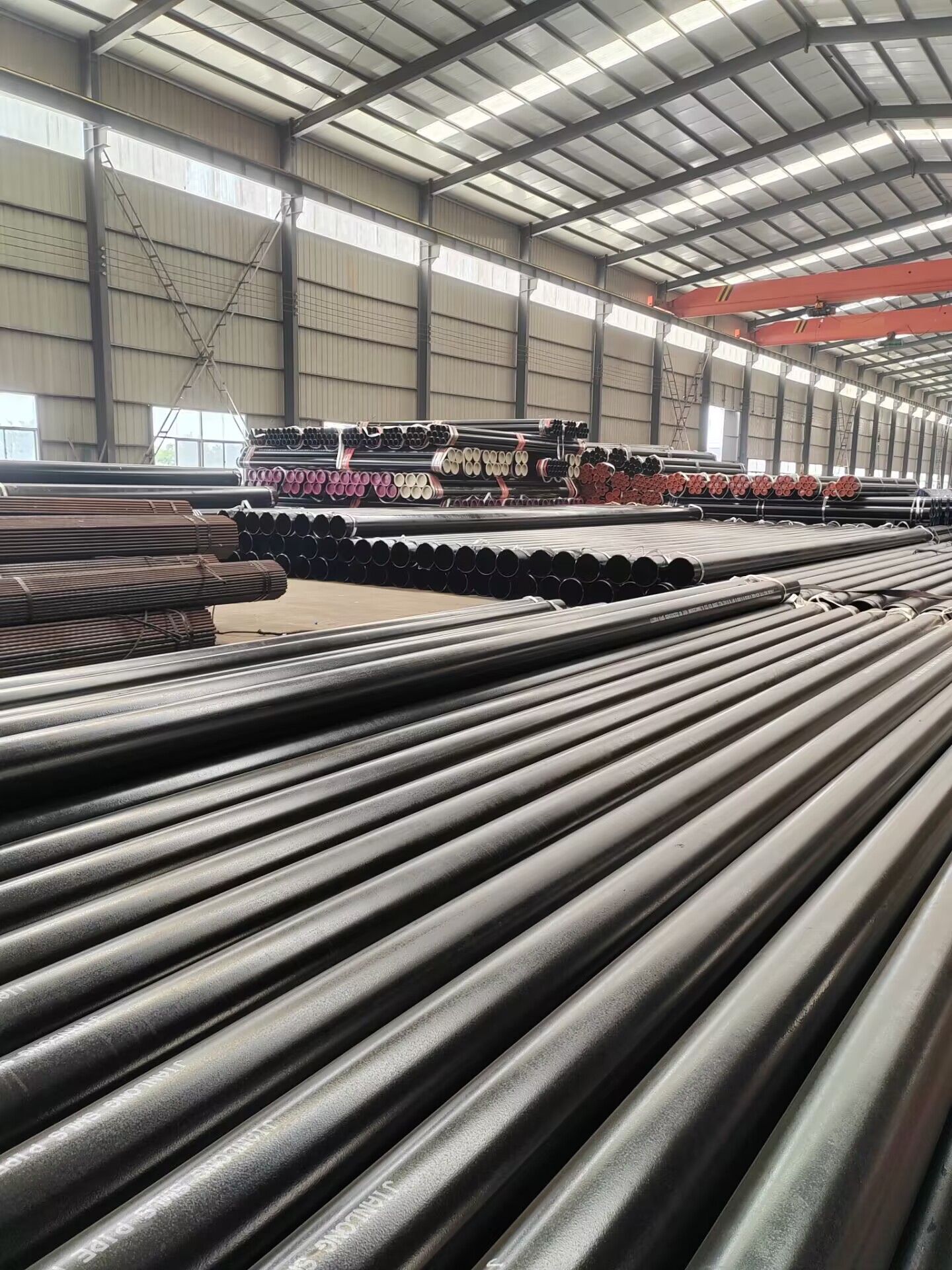

ERW stands for Electric Resistance Welding, which is a method of manufacturing steel pipes by forming them into a cylindrical shape and then welding the edges together using an electric current. This process results in a Seamless and strong pipe that is ideal for a wide range of applications.

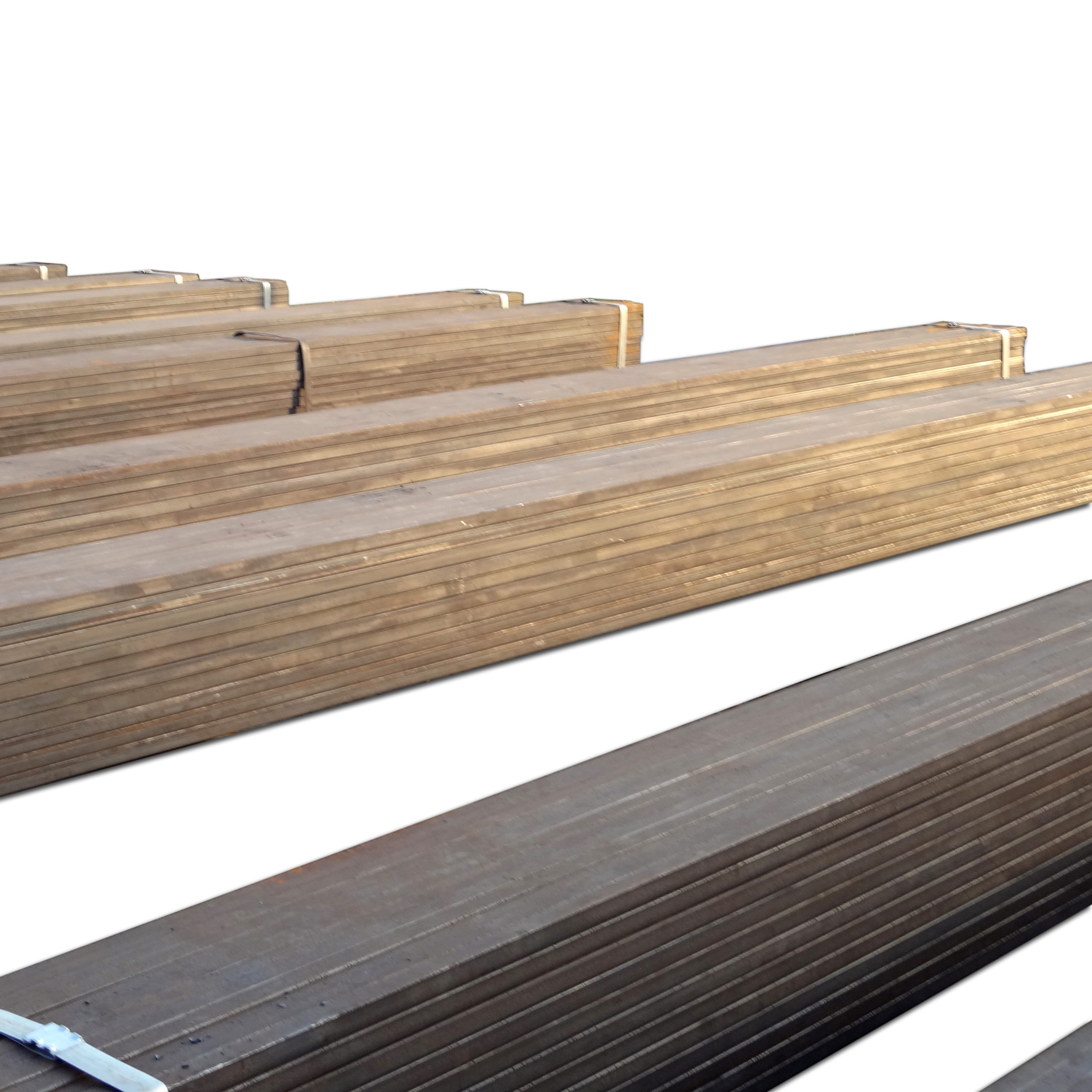

One of the main benefits of using ERW cold rolled stainless steel pipe is its high level of precision and consistency. The Cold rolling process involves passing the steel through a series of rollers at room temperature, which helps to improve the surface finish and dimensional accuracy of the pipe. This means that ERW cold rolled Stainless steel pipes have a smooth and uniform surface that is free from defects, making them ideal for applications where appearance and performance are important.

2.75 od exhaust pipe

In addition to their precision and consistency, ERW cold rolled stainless steel pipes are also known for their high strength and durability. The cold rolling process helps to increase the strength of the steel by compressing and hardening the material, resulting in a pipe that can withstand high pressure and temperature conditions. This makes ERW cold rolled stainless steel pipes suitable for a wide range of industrial applications, including construction, automotive, and manufacturing.

Another advantage of using ERW cold rolled stainless steel pipes is their resistance to corrosion. Stainless steel is inherently resistant to rust and corrosion, but the cold rolling process further enhances this property by improving the surface finish and removing impurities from the material. This means that ERW cold rolled stainless steel pipes are highly durable and long-lasting, making them a cost-effective choice for projects that require a reliable and low-maintenance piping solution.

Furthermore, ERW cold rolled stainless steel pipes are easy to work with and can be customized to meet specific project requirements. They can be easily cut, welded, and shaped to fit a variety of applications, making them a versatile and flexible choice for a wide range of projects. Whether you need a round, square, or rectangular pipe, ERW cold rolled stainless steel pipes can be manufactured to your exact specifications, ensuring a perfect fit and seamless installation.

In conclusion, ERW cold rolled stainless steel pipes offer a range of benefits that make them an ideal choice for industrial applications. From their precision and consistency to their strength and durability, ERW cold rolled stainless steel pipes are a reliable and cost-effective solution for projects that require high-quality piping. Whether you are working on a construction project, automotive application, or manufacturing process, ERW cold rolled stainless steel pipes can provide the performance and reliability you need to get the job done right.

Step-by-Step Guide to Polishing Stainless Steel Pipes for a Professional Finish

Stainless steel pipes are a popular choice for a variety of applications due to their durability, corrosion resistance, and aesthetic appeal. However, in order to achieve a professional finish, it is important to properly polish the surface of the pipes. Polishing stainless steel pipes not only enhances their appearance but also helps to remove any imperfections or blemishes that may be present.

One method of polishing stainless steel pipes is through the use of a 2b/polishing drawing ERW cold rolled round/square/rectangular seamless stainless steel pipe. This process involves using a series of abrasive materials to gradually smooth and refine the surface of the pipe, resulting in a mirror-like finish.

To begin the polishing process, it is important to first clean the surface of the stainless steel pipe to remove any dirt, grease, or other contaminants. This can be done using a mild detergent and water, followed by a thorough rinse and drying with a clean cloth. Once the surface is clean, the polishing process can begin.

The first step in polishing stainless steel pipes is to use a coarse abrasive material, such as a sanding disc or belt, to remove any surface imperfections or scratches. This step helps to prepare the surface for the finer polishing stages that will follow. It is important to use even pressure and consistent strokes to ensure a uniform finish.

After the initial rough polishing stage is complete, the next step is to use a finer abrasive material, such as a polishing wheel or buffing pad, to further refine the surface of the stainless steel pipe. This stage helps to smooth out any remaining imperfections and create a more polished appearance. Again, it is important to use even pressure and consistent strokes to achieve a uniform finish.

As the polishing process progresses, it may be necessary to switch to even finer abrasive materials to achieve the desired level of polish. This may involve using polishing compounds or pastes to further refine the surface of the stainless steel pipe. It is important to follow the manufacturer’s instructions for the specific abrasive materials being used to ensure optimal results.

Once the polishing process is complete, it is important to thoroughly clean the surface of the stainless steel pipe to remove any residue from the polishing compounds or pastes. This can be done using a mild detergent and water, followed by a thorough rinse and drying with a clean cloth. This final step helps to ensure a clean and professional finish.

In conclusion, polishing stainless steel pipes using a 2b/polishing drawing ERW cold rolled round/square/rectangular seamless stainless steel pipe is a highly effective method for achieving a professional finish. By following the steps outlined in this article and using the appropriate abrasive materials, it is possible to create a mirror-like finish that enhances the appearance of the stainless steel pipe. With proper care and maintenance, polished stainless steel pipes can maintain their appearance and durability for years to come.