Benefits of Choosing Factory Direct Sales for Low Carbon Seamless steel Pipe

When it comes to purchasing low carbon seamless steel pipe, there are many factors to consider. One of the most important decisions you will make is where to buy your steel pipe from. While there are many options available, one of the best choices you can make is to buy directly from the factory. Factory direct sales offer a number of benefits that can save you time, money, and hassle in the long run.

csst propane lineOne of the main advantages of choosing factory direct sales for low carbon seamless steel pipe is the cost savings. By cutting out the middleman, you can often get a better price on your steel pipe. This is because factories are able to offer lower prices since they do not have to pay additional markups to distributors or retailers. In addition, buying directly from the factory can also help you avoid hidden fees or extra charges that can drive up the cost of your purchase.

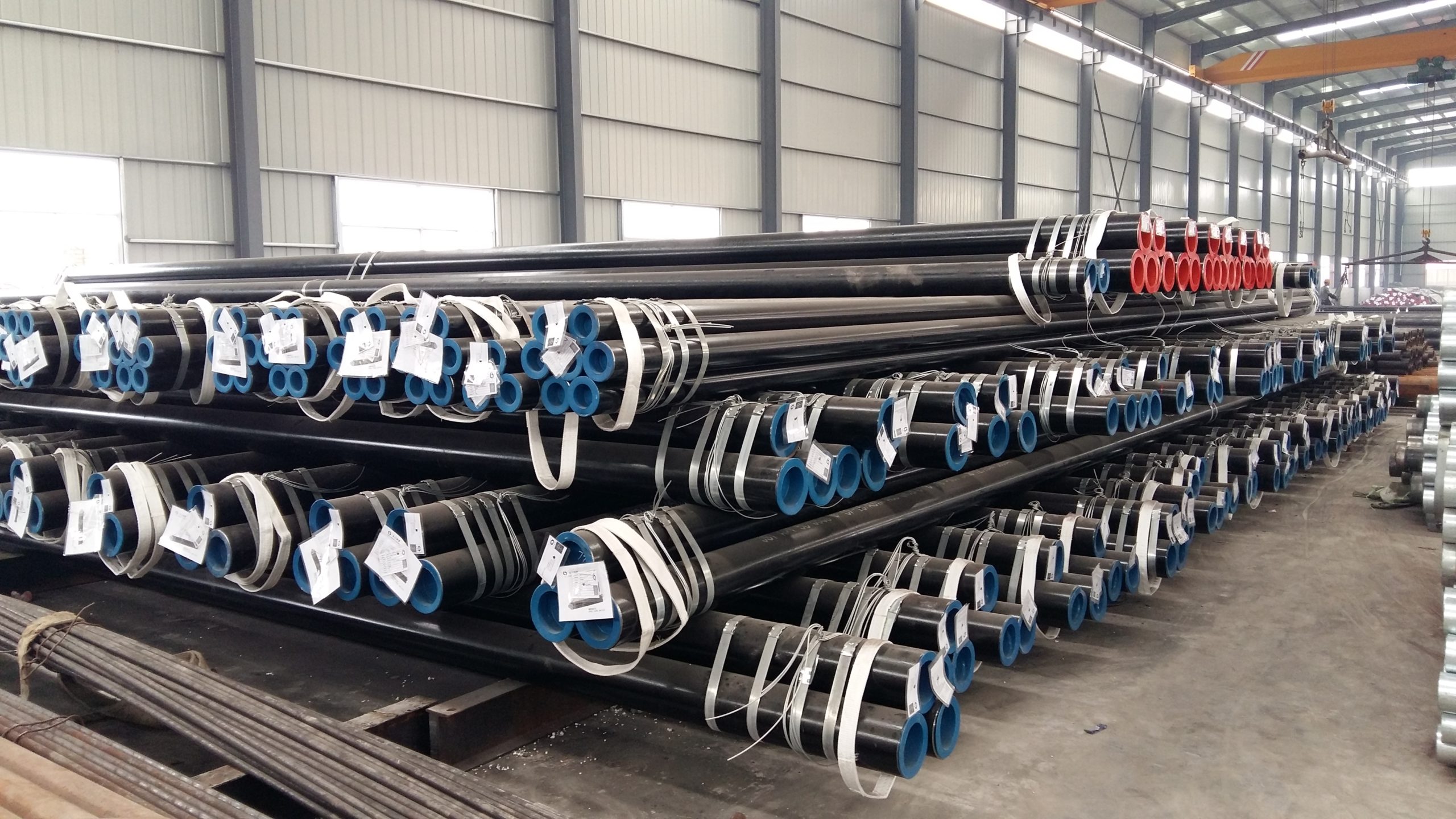

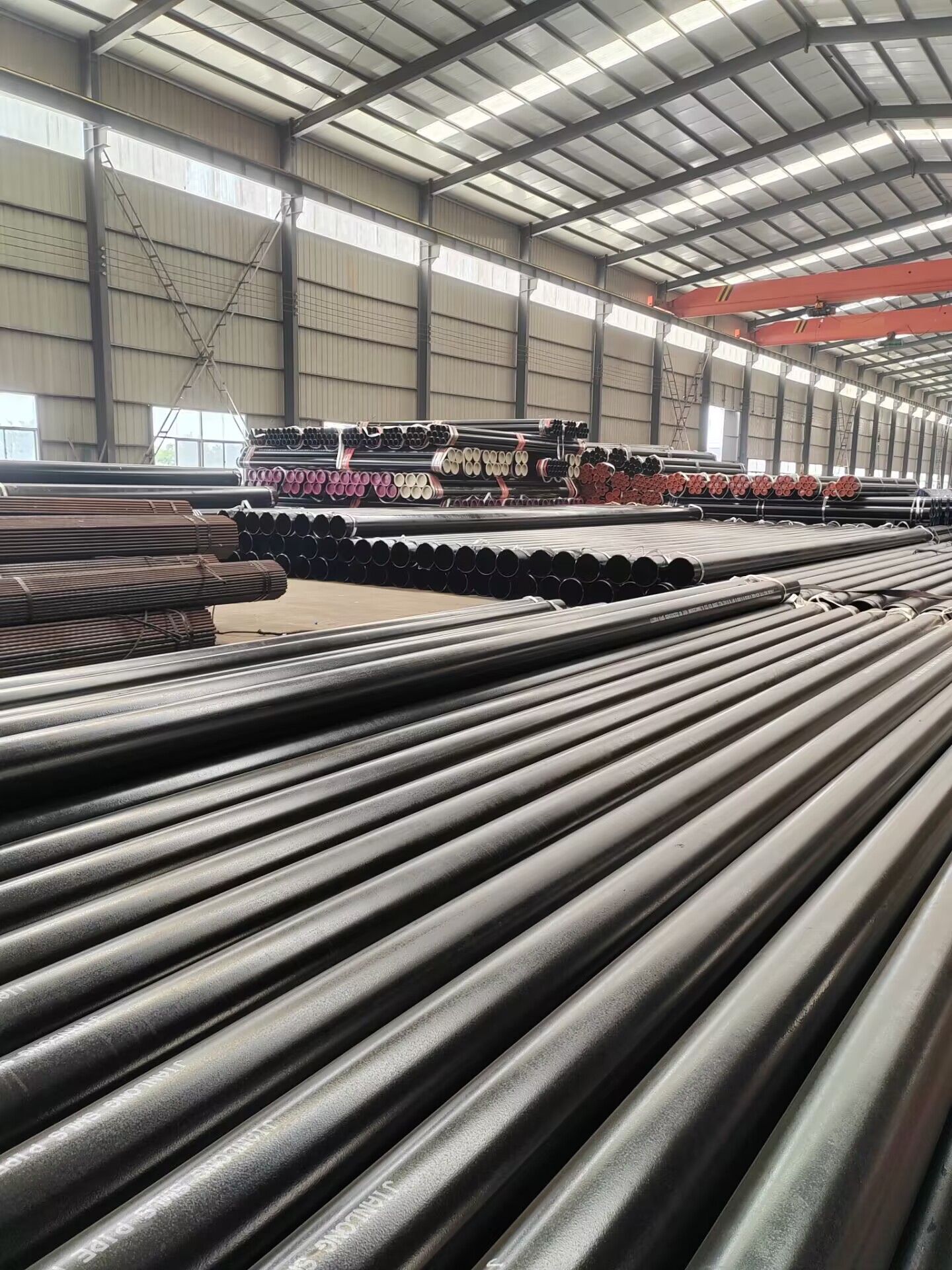

Another benefit of factory direct sales is the quality of the product you will receive. When you buy directly from the factory, you can be sure that you are getting a high-quality product that meets all industry standards. This is because factories have strict quality control measures in place to ensure that their products are of the highest quality. By purchasing directly from the factory, you can have peace of mind knowing that you are getting a reliable and durable product that will meet your needs.

In addition to cost savings and quality assurance, factory direct sales also offer greater flexibility and customization options. When you buy directly from the factory, you can often request customizations or modifications to your steel pipe to better suit your specific needs. This can include changes to the size, shape, or Material of the pipe, as well as additional features or coatings. By working directly with the factory, you can ensure that you are getting a product that is tailored to your exact specifications.

Furthermore, factory direct sales can also offer faster delivery times and better customer service. When you buy directly from the factory, you can often expect shorter lead times and quicker delivery of your steel pipe. This is because factories have the ability to produce and ship products more efficiently than distributors or retailers. In addition, working directly with the factory can also provide you with better customer service and support. If you have any questions or concerns about your purchase, you can easily contact the factory for assistance.

Overall, choosing factory direct sales for low carbon seamless steel pipe offers a number of benefits that can help you save time, money, and hassle. By purchasing directly from the factory, you can enjoy cost savings, quality assurance, customization options, faster delivery times, and better customer service. If you are in the market for steel pipe, consider buying directly from the factory to take advantage of these benefits and get the best product possible.

Comparison of Q195, Q235, Q345, and Q215 Grades in ASTM, DIN, and JIS Standards for Seamless Steel Pipe

Factory direct sales of seamless steel pipes are a popular choice for many industries due to their high quality and durability. When it comes to selecting the right grade of steel pipe for a specific application, it is important to consider factors such as the material’s composition, strength, and Corrosion resistance. In this article, we will compare the Q195, Q235, Q345, and Q215 grades of seamless steel pipes in ASTM, DIN, and JIS standards to help you make an informed decision.

Q195 steel is a carbon structural steel that is widely used in China and is equivalent to ASTM A283 grade C and DIN St33. It has a minimum Yield strength of 195 MPa and a maximum carbon content of 0.12%. Q195 steel is suitable for general structural applications and is often used in construction, machinery, and transportation industries.

Q235 steel is a low Carbon steel that is commonly used in China and is equivalent to ASTM A36 and DIN St37-2. It has a minimum yield strength of 235 MPa and a maximum carbon content of 0.22%. Q235 steel is versatile and can be used in a variety of applications, including structural steel, machinery parts, and welded pipes.

Q345 steel is a high-strength low Alloy steel that is widely used in China and is equivalent to ASTM A572 grade 50 and DIN St52-3. It has a minimum yield strength of 345 MPa and a maximum carbon content of 0.20%. Q345 steel is known for its excellent weldability and toughness, making it suitable for structural applications in construction, bridges, and offshore platforms.

Q215 steel is a carbon structural steel that is commonly used in China and is equivalent to ASTM A283 grade D and DIN St44-2. It has a minimum yield strength of 215 MPa and a maximum carbon content of 0.15%. Q215 steel is often used in general structural applications, such as building frames, machinery parts, and automotive components.

When comparing the Q195, Q235, Q345, and Q215 grades of seamless steel pipes, it is important to consider the specific requirements of your application. Q195 and Q215 steel are suitable for general structural applications, while Q235 steel offers better weldability and versatility. Q345 steel is ideal for high-strength applications that require excellent toughness and weldability.

In terms of international standards, Q195, Q235, Q345, and Q215 grades of seamless steel pipes are equivalent to ASTM, DIN, and JIS standards. It is important to consult the relevant standards to ensure that the steel pipe meets the necessary requirements for your application.

In conclusion, when selecting a grade of seamless steel pipe for your project, it is important to consider factors such as strength, weldability, and corrosion resistance. The Q195, Q235, Q345, and Q215 grades of seamless steel pipes offer a range of options for different applications, and consulting the relevant standards will help you make an informed decision. Factory direct sales of these steel pipes provide a cost-effective and reliable solution for your construction, machinery, or transportation needs.