Advantages of Using A312 TP304 Stainless steel Tube in Industrial Applications

Stainless steel is a versatile Material that is widely used in various industrial applications due to its excellent Corrosion resistance, durability, and strength. Among the different grades of stainless steel available, A312 TP304 is one of the most popular choices for Tubing and piping. In this article, we will explore the advantages of using A312 TP304 stainless Steel tube in industrial applications.

One of the key advantages of A312 TP304 stainless steel tube is its superior corrosion resistance. This grade of stainless steel contains a high percentage of chromium, which forms a protective oxide layer on the surface of the material. This oxide layer acts as a barrier against corrosive elements, such as water, chemicals, and salt, making A312 TP304 stainless steel tube ideal for use in harsh environments.

In addition to its corrosion resistance, A312 TP304 stainless steel tube also offers excellent strength and durability. This grade of stainless steel has a high Tensile strength and can withstand high temperatures and pressures, making it suitable for a wide range of industrial applications. Whether it is used in the construction of pipelines, heat exchangers, or pressure vessels, A312 TP304 stainless steel tube can provide reliable performance and long-lasting durability.

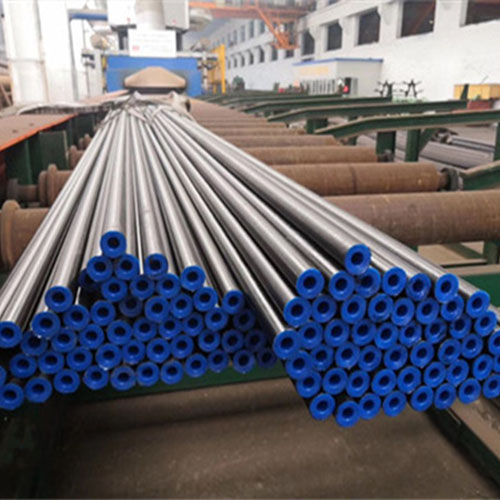

Another advantage of using A312 TP304 stainless steel tube is its versatility. This grade of stainless steel can be easily welded, fabricated, and machined to meet the specific requirements of different industrial applications. Whether you need a Seamless Pipe, welded pipe, square pipe, or rectangular pipe, A312 TP304 stainless steel tube can be customized to suit your needs.

Hollow section pipeFurthermore, A312 TP304 stainless steel tube is easy to maintain and clean, making it a cost-effective choice for industrial applications. Unlike other materials that require frequent maintenance and replacement, A312 TP304 stainless steel tube is resistant to rust, corrosion, and staining, ensuring a long service life and minimal downtime.

In conclusion, A312 TP304 stainless steel tube offers a wide range of advantages for industrial applications. From its superior corrosion resistance and strength to its versatility and ease of maintenance, this grade of stainless steel is a reliable and cost-effective choice for a variety of industries. Whether you are looking for a seamless pipe, welded pipe, square pipe, or rectangular pipe, A312 TP304 stainless steel tube can meet your needs and provide reliable performance in even the harshest environments.

Comparison of A312 TP316L and A312 TP321 Stainless steel pipes for High-Temperature Environments

Stainless steel pipes are widely used in various industries due to their excellent corrosion resistance, high strength, and durability. Two popular grades of stainless steel pipes that are commonly used in high-temperature environments are A312 TP316L and A312 TP321. In this article, we will compare these two grades of stainless steel pipes to help you make an informed decision for your specific application.

A312 TP316L is a low carbon version of A312 TP316 stainless steel, which is known for its excellent corrosion resistance and high temperature strength. It contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, which gives it superior corrosion resistance in a wide range of environments. A312 TP316L is commonly used in applications where high corrosion resistance is required, such as in chemical processing, pharmaceutical, and food processing industries.

On the other hand, A312 TP321 is a titanium-stabilized austenitic stainless steel that offers excellent corrosion resistance and high temperature strength. It contains 17-19% chromium, 9-12% nickel, and 0.7% titanium, which helps to prevent carbide precipitation during Welding and high-temperature exposure. A312 TP321 is commonly used in applications where high temperature strength is required, such as in heat exchangers, furnace parts, and exhaust systems.

One of the key differences between A312 TP316L and A312 TP321 is their carbon content. A312 TP316L has a maximum carbon content of 0.03%, while A312 TP321 has a maximum carbon content of 0.08%. The lower carbon content in A312 TP316L helps to reduce the risk of carbide precipitation and sensitization, which can lead to intergranular corrosion in high-temperature environments. On the other hand, the higher carbon content in A312 TP321 provides improved high-temperature strength and creep resistance.

In terms of Mechanical properties, A312 TP316L and A312 TP321 have similar tensile strength and Yield strength. However, A312 TP321 has a higher tensile strength at elevated temperatures due to its titanium stabilization. This makes A312 TP321 a better choice for applications that require high temperature strength and resistance to thermal cycling.

When it comes to welding, both A312 TP316L and A312 TP321 are easily weldable using common welding techniques. However, A312 TP321 is more prone to sensitization and carbide precipitation during welding, which can lead to intergranular corrosion in high-temperature environments. To prevent this, it is recommended to use low carbon filler metals and to perform post-weld heat treatment on A312 TP321 stainless steel pipes.

In conclusion, both A312 TP316L and A312 TP321 are excellent choices for high-temperature applications due to their superior corrosion resistance, high temperature strength, and weldability. The choice between these two grades of stainless steel pipes will ultimately depend on the specific requirements of your application. If you need a stainless steel pipe with low carbon content and excellent corrosion resistance, A312 TP316L is the ideal choice. On the other hand, if you need a stainless steel pipe with higher carbon content and improved high-temperature strength, A312 TP321 is the better option.