Advantages of Using ASTM A36, A179, and A192 steel Pipes in Large Diameter Spiral Welded Tubes

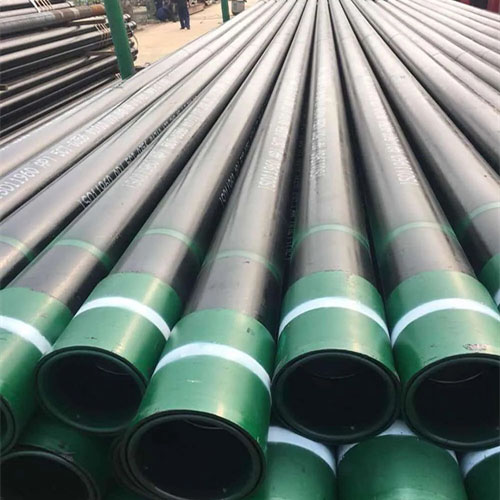

Steel pipes are an essential component in various industries, from construction to manufacturing. When it comes to large diameter spiral welded tubes, the choice of Material is crucial to ensure durability, strength, and longevity. ASTM A36, A179, and A192 steel pipes are popular choices for these applications due to their unique properties and advantages.

One of the key advantages of using ASTM A36 steel pipes in large diameter spiral welded tubes is their high strength and durability. ASTM A36 is a low Carbon steel that is widely used in construction and structural applications due to its excellent Mechanical properties. It is known for its high Tensile strength and impact resistance, making it ideal for heavy-duty applications such as pipelines and structural supports.

In addition to its strength, ASTM A36 steel pipes are also highly versatile and can be easily welded, formed, and machined to meet specific requirements. This flexibility allows for customization and ensures a perfect fit for any project. Whether it’s a round, square, or rectangular tube, ASTM A36 steel pipes can be seamlessly integrated into any design.

Another popular choice for large diameter spiral welded tubes is ASTM A179 steel pipes. ASTM A179 is a Seamless carbon steel Pipe that is commonly used in heat exchangers and condensers due to its excellent thermal conductivity and Corrosion resistance. This makes it an ideal choice for applications where temperature control and efficiency are critical.

Stainless steel square tubingThe seamless nature of ASTM A179 steel pipes also ensures a smooth flow of fluids, reducing pressure drop and improving overall performance. This is particularly important in industries such as Oil and gas, where efficiency and reliability are paramount. Additionally, the seamless construction of ASTM A179 steel pipes eliminates the risk of leaks and ensures a tight seal, further enhancing their durability and longevity.

For applications that require even higher temperature resistance, ASTM A192 steel pipes are the preferred choice. ASTM A192 is a high carbon steel pipe that is specifically designed for high-pressure and high-temperature applications, such as boilers and superheaters. Its superior heat resistance and thermal conductivity make it an ideal choice for industries where extreme conditions are common.

In addition to their High temperature resistance, ASTM A192 steel pipes are also known for their excellent corrosion resistance, ensuring long-term performance and reliability. This makes them a popular choice for applications where exposure to harsh environments is a concern.

Overall, the use of ASTM A36, A179, and A192 steel pipes in large diameter spiral welded tubes offers numerous advantages, including high strength, durability, versatility, and temperature resistance. These properties make them ideal for a wide range of applications in various industries, from construction to manufacturing. By choosing the right material for your project, you can ensure optimal performance and longevity for your large diameter spiral welded tubes.

A Comprehensive Guide to Galvanized Carbon and Stainless steel pipes for Hot and Cold Round, Square, and Rectangular Metal Seamless Tubes

When it comes to choosing the right type of steel pipe for your project, there are a variety of options available on the market. Two popular choices are galvanized carbon steel and stainless steel pipes. These pipes are commonly used in a wide range of applications, from construction and infrastructure projects to plumbing and HVAC systems. In this comprehensive guide, we will explore the differences between galvanized carbon and stainless steel pipes, as well as the various types of pipes available, including hot and cold round, square, and rectangular metal seamless tubes.

Galvanized carbon steel pipes are coated with a layer of zinc to protect the underlying steel from corrosion. This makes them ideal for outdoor applications where the pipes will be exposed to the elements. Galvanized carbon steel pipes are also commonly used in plumbing systems, as the zinc coating helps prevent rust and corrosion, extending the lifespan of the pipes.

Stainless steel pipes, on the other hand, are made from a combination of steel and chromium, which gives them excellent corrosion resistance. Stainless steel pipes are often used in applications where hygiene is a concern, such as in food processing plants and medical facilities. They are also commonly used in high-temperature and high-pressure applications, as they are able to withstand extreme conditions without corroding or degrading.

When it comes to choosing the right type of steel pipe for your project, it is important to consider the specific requirements of your application. Galvanized carbon steel pipes are a cost-effective option for outdoor applications and plumbing systems, while stainless steel pipes are better suited for high-temperature and high-pressure applications where corrosion resistance is a priority.

In addition to choosing between galvanized carbon and stainless steel pipes, you will also need to consider the size and shape of the pipes. Round, square, and rectangular metal seamless tubes are all available in a variety of sizes and dimensions to suit your specific needs. Whether you need a large diameter Spiral welded pipe or a smaller seamless tube, there are options available to meet your requirements.

ASTM A36, A179, and A192 are all common specifications for steel pipes, each with its own set of properties and characteristics. ASTM A36 is a standard specification for carbon structural steel, while ASTM A179 and A192 are specifications for seamless cold-drawn low-carbon steel tubes for heat exchangers and boilers. These specifications ensure that the pipes meet certain quality standards and performance requirements, making them suitable for a wide range of applications.

In conclusion, when it comes to choosing the right steel pipe for your project, there are a variety of options available, including galvanized carbon and stainless steel pipes. By considering the specific requirements of your application and choosing the appropriate size and shape of the pipes, you can ensure that your project is completed successfully. Whether you need a large diameter spiral welded pipe or a small seamless tube, there are options available to meet your needs. ASTM A36, A179, and A192 are all common specifications for steel pipes, each with its own unique properties and characteristics. By understanding the differences between these specifications, you can make an informed decision about which type of pipe is best suited for your project.