Advantages of Using A790 S32205 Stainless steel Seamless Pipe in Industrial Applications

Stainless steel is a versatile Material that is widely used in various industrial applications due to its excellent Corrosion resistance, durability, and strength. One popular grade of stainless steel that is commonly used in industrial settings is A790 S32205, also known as SUS304. This grade of stainless steel is a duplex stainless steel that offers a unique combination of properties that make it ideal for a wide range of applications.

One of the main advantages of using A790 S32205 stainless steel seamless pipe in industrial applications is its superior corrosion resistance. This grade of stainless steel contains a high level of chromium and molybdenum, which helps to protect the material from corrosion in harsh environments. This makes A790 S32205 stainless steel seamless pipe ideal for use in industries such as chemical processing, Oil and gas, and marine applications where corrosion resistance is essential.

In addition to its corrosion resistance, A790 S32205 stainless steel seamless pipe also offers excellent strength and durability. This grade of stainless steel has a high Tensile strength and can withstand high temperatures and pressures, making it suitable for use in demanding industrial applications. The seamless construction of A790 S32205 stainless steel pipe also ensures that it is strong and leak-proof, providing a reliable and long-lasting solution for industrial piping systems.

Another advantage of using A790 S32205 stainless steel seamless pipe is its versatility. This grade of stainless steel can be easily welded and fabricated into various shapes and sizes, making it suitable for a wide range of applications. Whether you need a straight pipe, a bend, or a custom fitting, A790 S32205 stainless steel seamless pipe can be easily customized to meet your specific requirements.

Furthermore, A790 S32205 stainless steel seamless pipe is easy to maintain and clean, making it a cost-effective solution for industrial applications. This grade of stainless steel is resistant to staining and rusting, and can be easily cleaned with mild soap and water. This helps to reduce maintenance costs and ensures that your piping system remains in optimal condition for years to come.

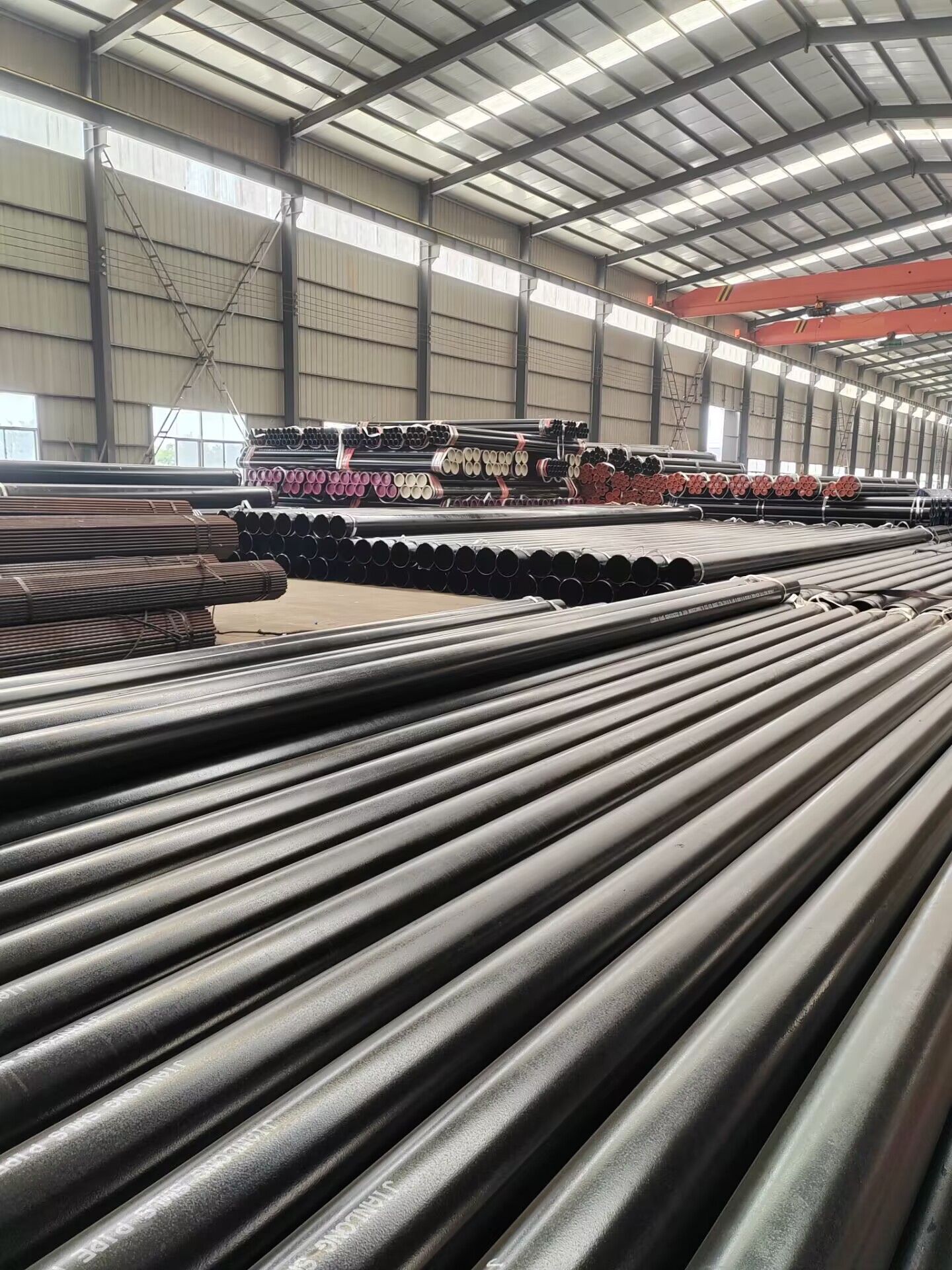

stainless steel hollow pipe

Overall, A790 S32205 stainless steel seamless pipe offers a range of advantages that make it an ideal choice for industrial applications. From its superior corrosion resistance and strength to its versatility and ease of maintenance, this grade of stainless steel provides a reliable and durable solution for a wide range of industrial piping systems. Whether you are working in the chemical processing, oil and gas, or marine industry, A790 S32205 stainless steel seamless pipe is a reliable and cost-effective option that will meet your needs and exceed your expectations.

Comparison Between A790 S32205 and SUS304 Stainless Steel Seamless Pipes

Stainless steel seamless pipes are widely used in various industries due to their durability, corrosion resistance, and high strength. Two popular grades of stainless steel seamless pipes are A790 S32205 and SUS304. In this article, we will compare these two grades to help you make an informed decision when choosing the right stainless steel seamless pipe for your project.

A790 S32205 is a duplex stainless steel that contains a combination of austenitic and ferritic phases. This grade offers excellent corrosion resistance, high strength, and good weldability. It is commonly used in applications where high corrosion resistance and strength are required, such as in the oil and gas industry, chemical processing, and marine environments. A790 S32205 seamless pipes are available in various sizes and schedules, including 4″ Sch80s.

On the other hand, SUS304 is an austenitic stainless steel that is known for its high corrosion resistance and excellent formability. It is commonly used in applications where high cleanliness and aesthetics are important, such as in the food and beverage industry, pharmaceuticals, and architectural applications. SUS304 seamless pipes are also available in various sizes and schedules, including 4″ Sch80s.

When comparing A790 S32205 and SUS304 stainless steel seamless pipes, one of the key differences is their chemical composition. A790 S32205 contains higher levels of chromium, molybdenum, and nitrogen compared to SUS304, which gives it superior corrosion resistance and strength. On the other hand, SUS304 contains higher levels of nickel and chromium, which gives it better formability and weldability.

In terms of Mechanical properties, A790 S32205 has higher tensile and Yield strength compared to SUS304. This makes A790 S32205 more suitable for applications where high strength is required, such as in structural components and pressure vessels. On the other hand, SUS304 has higher elongation and impact resistance, making it more suitable for applications where formability and toughness are important.

When it comes to corrosion resistance, both A790 S32205 and SUS304 offer excellent protection against corrosion in a wide range of environments. However, A790 S32205 is more resistant to chloride-induced stress corrosion cracking, making it a better choice for applications where exposure to chloride ions is a concern.

In terms of cost, A790 S32205 is generally more expensive than SUS304 due to its higher alloy content and superior mechanical properties. However, the higher cost of A790 S32205 is often justified by its superior performance and longer service life.

In conclusion, both A790 S32205 and SUS304 stainless steel seamless pipes have their own unique properties and advantages. The choice between these two grades will ultimately depend on the specific requirements of your project, such as corrosion resistance, strength, formability, and cost. It is important to carefully consider these factors and consult with a stainless steel expert to determine the best stainless steel seamless pipe for your application.