Advantages of ASTM A106-19: Seamless Carbon steel Pipes in Industrial Applications

ASTM A106-19: Seamless Carbon Steel Pipe Standard

Seamless carbon steel pipes have long been a staple in various industrial applications, providing a reliable means of transporting fluids and gases under high-pressure and high-temperature conditions. Among the numerous standards governing the production and quality of these pipes, ASTM A106-19 stands out as a key benchmark. This standard, maintained by the American Society for Testing and Materials (ASTM), establishes the requirements for seamless carbon steel pipe suitable for high-temperature service.

One of the primary advantages of ASTM A106-19 compliant pipes lies in their superior strength and durability. Carbon steel, known for its robustness and resilience, ensures that these pipes can withstand extreme conditions without succumbing to deformation or failure. This characteristic makes them particularly well-suited for applications in industries such as Oil and gas, petrochemicals, power generation, and refineries, where reliability is paramount.

Moreover, the seamless nature of ASTM A106-19 pipes offers distinct advantages over welded alternatives. Seamless pipes lack the welded seam present in welded pipes, which eliminates potential weak points prone to corrosion and leakage. This seamless construction enhances the integrity of the pipeline, reducing the risk of costly maintenance and repair operations over the long term.

Another significant benefit of ASTM A106-19 compliant pipes is their uniformity and consistency in dimensions and properties. The standard specifies rigorous requirements for manufacturing processes, including chemical composition, Mechanical properties, and testing procedures. As a result, users can expect uniformity in Wall thickness, outer diameter, and other critical dimensions, ensuring compatibility and ease of installation across various applications.

Furthermore, ASTM A106-19 ensures that the pipes meet stringent quality standards through comprehensive testing protocols. These tests evaluate the mechanical properties, including Tensile strength, Yield strength, and elongation, as well as non-destructive examinations to detect any flaws or imperfections. By adhering to these rigorous testing procedures, manufacturers can guarantee the integrity and reliability of their products, instilling confidence in end-users.

In addition to their mechanical properties, ASTM A106-19 compliant pipes offer excellent Corrosion resistance, particularly in harsh environments exposed to corrosive substances or high temperatures. The carbon steel composition, combined with proper surface treatment and coating, enhances the pipes’ ability to withstand corrosion, prolonging their service life and minimizing maintenance requirements.

Moreover, ASTM A106-19 pipes facilitate efficient fluid flow due to their smooth internal surface finish. Unlike welded pipes, which may have irregularities and rough edges at the welded seam, seamless pipes provide a seamless interior surface, reducing frictional resistance and pressure drop. This smooth flow characteristic not only improves operational efficiency but also reduces energy consumption, making ASTM A106-19 pipes a cost-effective choice for fluid transportation systems.

In conclusion, ASTM A106-19 sets the standard for seamless carbon steel pipes used in high-temperature industrial applications. The advantages of these pipes, including superior strength, durability, uniformity, and corrosion resistance, make them indispensable in industries where reliability and performance are critical. By adhering to ASTM A106-19 specifications, manufacturers and end-users alike can ensure the integrity and longevity of their piping systems, contributing to safer and more efficient operations.

Understanding the Specifications and Requirements of ASTM A106-19: Seamless Carbon Steel Pipe Standard

ASTM A106-19: Seamless Carbon Steel Pipe Standard is a critical specification in the realm of industrial piping. This standard, set forth by the American Society for Testing and Materials (ASTM), delineates the requirements for seamless carbon steel pipe intended for high-temperature service. Understanding its specifications and requirements is crucial for professionals in various industries, including manufacturing, construction, and engineering.

At its core, ASTM A106-19 ensures that seamless carbon steel pipes meet stringent criteria to withstand elevated temperatures and pressures encountered in various applications. These pipes find extensive use in industries such as oil and gas, petrochemicals, power generation, and refineries, where reliability and performance are paramount.

One of the key aspects of ASTM A106-19 is its emphasis on seamless manufacturing processes. Unlike welded pipes, seamless pipes are devoid of any longitudinal or circumferential welded joints, making them inherently stronger and more suitable for high-pressure environments. This standard specifies that the pipe Material must be produced either by seamless method or by the hot-finished or cold-finished process.

Furthermore, ASTM A106-19 delineates the chemical composition requirements for seamless carbon steel pipes. This includes specifications for carbon, manganese, phosphorus, sulfur, silicon, chromium, copper, nickel, molybdenum, and vanadium content. These stringent chemical composition requirements ensure the mechanical properties and corrosion resistance of the pipes meet the necessary standards.

In addition to chemical composition, ASTM A106-19 also outlines mechanical properties such as tensile strength, yield strength, and elongation. These properties are vital indicators of the pipe’s ability to withstand mechanical stress and deformation under high temperatures and pressures. Compliance with these mechanical requirements is essential to ensure the integrity and safety of the piping systems in which the pipes are used.

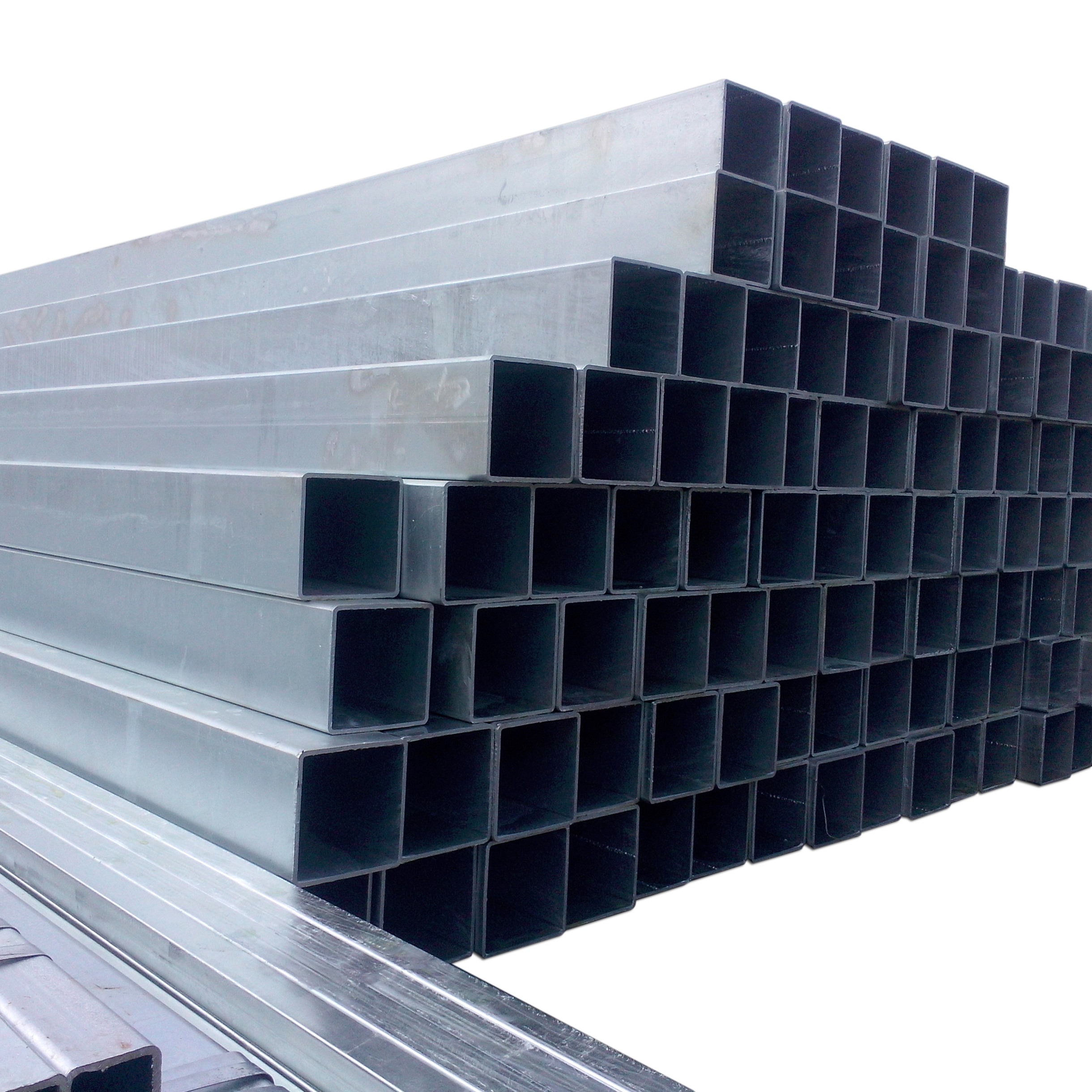

rectangular hollowMoreover, ASTM A106-19 specifies various tests and inspection procedures to ensure the quality and integrity of seamless carbon steel pipes. These include hydrostatic testing, nondestructive testing (such as Ultrasonic testing or eddy current testing), tensile testing, and impact testing. By subjecting the pipes to rigorous testing protocols, manufacturers can identify any defects or imperfections that could compromise their performance in service.

It’s worth noting that ASTM A106-19 provides different grades of seamless carbon steel pipes, namely Grade A, Grade B, and Grade C, each with varying tensile and yield strength requirements. The selection of the appropriate grade depends on factors such as the operating temperature, pressure, and specific application requirements.

In conclusion, ASTM A106-19 plays a pivotal role in ensuring the quality, reliability, and performance of seamless carbon steel pipes used in high-temperature service. By adhering to its specifications and requirements, manufacturers can produce pipes that meet the demanding needs of various industries. Understanding the intricacies of this standard is essential for professionals involved in the design, fabrication, and installation of piping systems, ultimately contributing to the safety and efficiency of industrial operations.