Advantages of Using a Table of Standard Seamless steel Pipe Specifications

Standard seamless steel pipes are an indispensable component of various industries, serving as the backbone of infrastructure projects, manufacturing processes, and energy production. With their robustness, reliability, and versatility, these pipes have become a cornerstone in countless applications worldwide. However, navigating through the myriad of specifications and dimensions can be a daunting task for engineers, procurement specialists, and project managers. This is where a table of standard seamless steel pipe specifications proves to be invaluable.

Firstly, such a table serves as a comprehensive reference point, consolidating vital information into a single, easily accessible resource. Engineers and designers often require precise details regarding pipe dimensions, Wall thickness, Material composition, and allowable pressure ratings to ensure compliance with project requirements and industry standards. Without a centralized reference, locating and comparing this information across various sources can be time-consuming and prone to errors.

Moreover, a table of standard seamless steel pipe specifications facilitates efficient decision-making during the procurement process. By presenting key parameters side by side, stakeholders can swiftly evaluate different options based on their project’s specific needs, budget constraints, and performance criteria. This streamlined approach not only saves time but also enhances procurement accuracy, mitigating the risk of costly errors or mismatches.

Furthermore, the standardized format of such tables enhances clarity and consistency across project documentation. Whether communicating with colleagues, suppliers, or regulatory bodies, having a universally understood reference point fosters effective communication and minimizes misunderstandings. This clarity is particularly crucial in multinational projects or industries with stringent compliance requirements, where adherence to standards is paramount.

Additionally, a table of standard seamless steel pipe specifications promotes interoperability and compatibility across diverse systems and components. Engineers often need to ensure that pipes sourced from different manufacturers or regions can seamlessly integrate within the existing infrastructure without compromising performance or safety. By providing a standardized framework for comparison, these tables facilitate interoperability assessments, enabling engineers to identify potential compatibility issues upfront and devise appropriate solutions.

Furthermore, the accessibility of such tables fosters knowledge sharing and continuous improvement within the industry. By centralizing technical data and specifications, these resources become invaluable learning tools for professionals at all career stages. Newcomers to the field can quickly familiarize themselves with industry norms and best practices, while seasoned veterans can stay abreast of the latest developments and emerging trends.

https://youtube.com/watch?v=5tqzxNlncw4

In conclusion, the advantages of using a table of standard seamless steel pipe specifications are manifold. From simplifying information retrieval and procurement decisions to enhancing communication and interoperability, these tables play a pivotal role in driving efficiency, quality, and reliability across diverse industries. As the demand for seamless steel pipes continues to rise in tandem with global infrastructure development and industrial expansion, the importance of standardized reference tools cannot be overstated. By leveraging these resources effectively, stakeholders can navigate the complexities of pipe selection and deployment with confidence, ensuring the success of their projects and the sustainability of their operations.

How to Select the Right Seamless Steel Pipe from a Standard Table

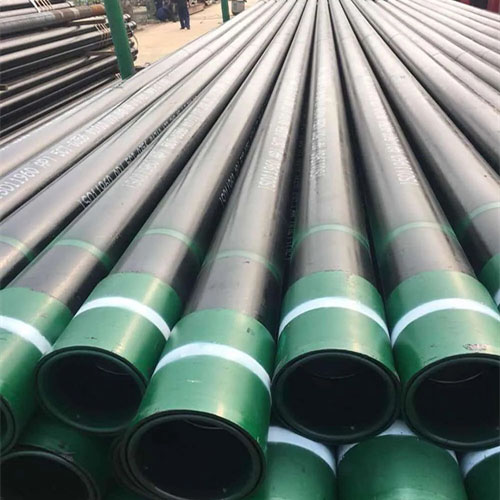

Selecting the right seamless steel pipe from a standard table is crucial for various industries, including construction, Oil and gas, automotive, and manufacturing. Seamless steel pipes offer numerous advantages, including durability, strength, and resistance to corrosion, making them ideal for various applications. However, with a wide range of options available, it can be challenging to determine which pipe best suits your needs. To simplify the selection process, many industries rely on standard tables that provide essential information about seamless steel pipes. These tables offer details such as pipe dimensions, material specifications, and performance characteristics, allowing engineers and project managers to make informed decisions.

One of the primary factors to consider when selecting a seamless steel pipe is its size. Standard tables categorize pipes based on their outer diameter, wall thickness, and Length. By referring to these tables, professionals can easily identify the dimensions that meet their project requirements. Additionally, standard tables often include information about pipe schedules, which indicate the pipe’s wall thickness and Pressure rating. This data is essential for ensuring that the selected pipe can withstand the intended operating conditions without failure.

rectangular steel tubingIn addition to size and schedule, material composition is another crucial aspect to consider when choosing a seamless steel pipe. Standard tables provide details about the grade of steel used in the pipe’s manufacturing, as well as any additional alloying elements present. These specifications impact the pipe’s Mechanical properties, such as Tensile strength, Yield strength, and Hardness. By consulting the standard table, engineers can select a pipe with the appropriate material composition to meet the specific performance requirements of their application.

Furthermore, standard tables often include information about surface finish and coating options for seamless steel pipes. Depending on the intended use and environmental conditions, certain surface treatments may be necessary to enhance Corrosion resistance or improve aesthetic appearance. Common surface finishes for seamless steel pipes include black oxide, galvanized, and coated with epoxy or polyethylene. By referring to the standard table, professionals can identify the most suitable surface finish for their project needs.

Moreover, standard tables provide valuable data regarding industry standards and specifications for seamless steel pipes. These standards ensure that pipes meet quality requirements and adhere to regulatory guidelines for safety and performance. By selecting pipes that comply with recognized standards such as ASTM, API, or DIN, professionals can have confidence in the reliability and consistency of the product. Additionally, standard tables may include information about certification and testing procedures to verify the quality and integrity of the seamless steel pipes.

In conclusion, selecting the right seamless steel pipe from a standard table requires careful consideration of various factors, including size, material composition, surface finish, and compliance with industry standards. By consulting standard tables, engineers and project managers can access essential information to make informed decisions about pipe selection for their applications. Whether it’s for construction, oil and gas, automotive, or manufacturing projects, choosing the appropriate seamless steel pipe is essential for ensuring performance, reliability, and safety. With standard tables as a valuable resource, professionals can navigate the vast array of options available and select the optimal pipe for their specific needs.