Benefits of Using ASTM A106 A53 Hot Rolled steel Pipe in Construction Projects

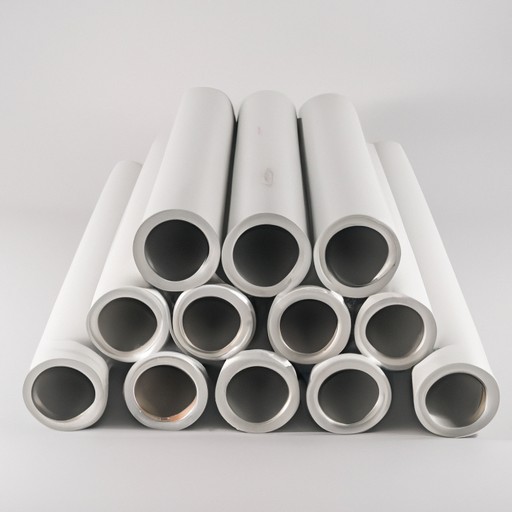

Steel pipes are a crucial component in construction projects, providing structural support and ensuring the integrity of buildings and infrastructure. When it comes to selecting the right type of steel pipe for a project, ASTM A106 A53 hot rolled steel pipe is a popular choice among construction professionals. This type of steel pipe is known for its durability, strength, and versatility, making it ideal for a wide range of applications.

One of the key benefits of using ASTM A106 A53 hot rolled steel pipe is its high Tensile strength. This means that the pipe can withstand heavy loads and pressure, making it suitable for use in structural applications where strength and durability are essential. Whether it’s supporting a building’s framework or carrying fluids and gases in a plumbing system, ASTM A106 A53 hot rolled steel pipe can handle the job with ease.

In addition to its strength, ASTM A106 A53 hot rolled steel pipe is also known for its excellent Corrosion resistance. This is particularly important in construction projects where the pipe will be exposed to harsh environmental conditions, such as moisture, chemicals, and extreme temperatures. By using a corrosion-resistant steel pipe, construction professionals can ensure that their projects will stand the test of time and remain structurally sound for years to come.

Another advantage of ASTM A106 A53 hot rolled steel pipe is its versatility. This type of steel pipe can be easily welded, bent, and shaped to fit a variety of design requirements, making it a flexible and cost-effective solution for construction projects of all sizes. Whether it’s used for plumbing, HVAC systems, or structural support, ASTM A106 A53 hot rolled steel pipe can be customized to meet the specific needs of a project.

Furthermore, ASTM A106 A53 hot rolled steel pipe is available in a wide range of sizes and thicknesses, making it suitable for a variety of applications. Whether you need a small diameter pipe for a residential plumbing project or a large diameter pipe for a commercial construction project, ASTM A106 A53 hot rolled steel pipe can be easily sourced to meet your requirements. This availability of sizes and thicknesses makes it a convenient option for construction professionals looking for a reliable and versatile steel pipe solution.

In conclusion, ASTM A106 A53 hot rolled steel pipe offers a range of benefits that make it an ideal choice for construction projects. From its high tensile strength and corrosion resistance to its versatility and availability in various sizes and thicknesses, this type of steel pipe is a reliable and cost-effective solution for a wide range of applications. By choosing ASTM A106 A53 hot rolled steel pipe for your next construction project, you can ensure that your structures are built to last and withstand the test of time.

Comparison of Different Grades of Carbon Seamless steel pipe: 4120, 4130, 4140, 42CrMo4, Scm440

ASTM A106 A53 Hot Rolled Steel Pipe Mild Ms Steel tube 4120 4130 4140 42CrMo4 Scm440 Sch40 Carbon Seamless Steel Pipe

Carbon seamless steel pipes are widely used in various industries due to their high strength, durability, and resistance to corrosion. Among the different grades available, 4120, 4130, 4140, 42CrMo4, and Scm440 are some of the most commonly used grades for carbon seamless steel pipes. In this article, we will compare these grades to help you understand their differences and applications.

4120 is a low-Alloy steel grade that offers good weldability and machinability. It contains chromium and molybdenum, which enhance its strength and toughness. 4130, on the other hand, is a chromium-molybdenum alloy steel that is known for its high tensile strength and excellent impact resistance. It is often used in the aerospace and automotive industries for applications that require high strength-to-Weight ratios.

4140 is a versatile steel grade that is commonly used in the Oil and gas industry for making drill collars, drill pipes, and other components that require high strength and toughness. It has a high carbon content, which gives it excellent hardenability and wear resistance. 42CrMo4 is a similar grade to 4140 but with slightly different chemical composition. It is widely used in the automotive and machinery industries for making gears, shafts, and other components that require high strength and Fatigue resistance.

Scm440 is a Japanese grade of steel that is equivalent to 4140 in terms of chemical composition and Mechanical properties. It is commonly used in the manufacturing of tools, dies, and machine parts that require high strength and wear resistance. All these grades of carbon seamless steel pipes are available in various sizes and thicknesses to meet the specific requirements of different applications.

When it comes to choosing the right grade of carbon seamless steel pipe for your project, it is important to consider the specific requirements of the application. 4120 and 4130 are suitable for applications that require good weldability and machinability, while 4140, 42CrMo4, and Scm440 are ideal for applications that require high strength, toughness, and wear resistance. It is also important to consider the size and thickness of the pipe to ensure that it can withstand the required load and pressure.

In conclusion, ASTM A106 A53 hot rolled steel pipe mild MS steel tube 4120 4130 4140 42CrMo4 Scm440 Sch40 carbon seamless steel pipe are all excellent choices for various industrial applications. Each grade offers unique properties that make it suitable for specific applications. By understanding the differences between these grades, you can choose the right carbon seamless steel pipe for your project and ensure its success.