Benefits of Using API 5L, ASTM A106, and A53 Grade B Seamless Pipes in Oil and Gas Pipelines

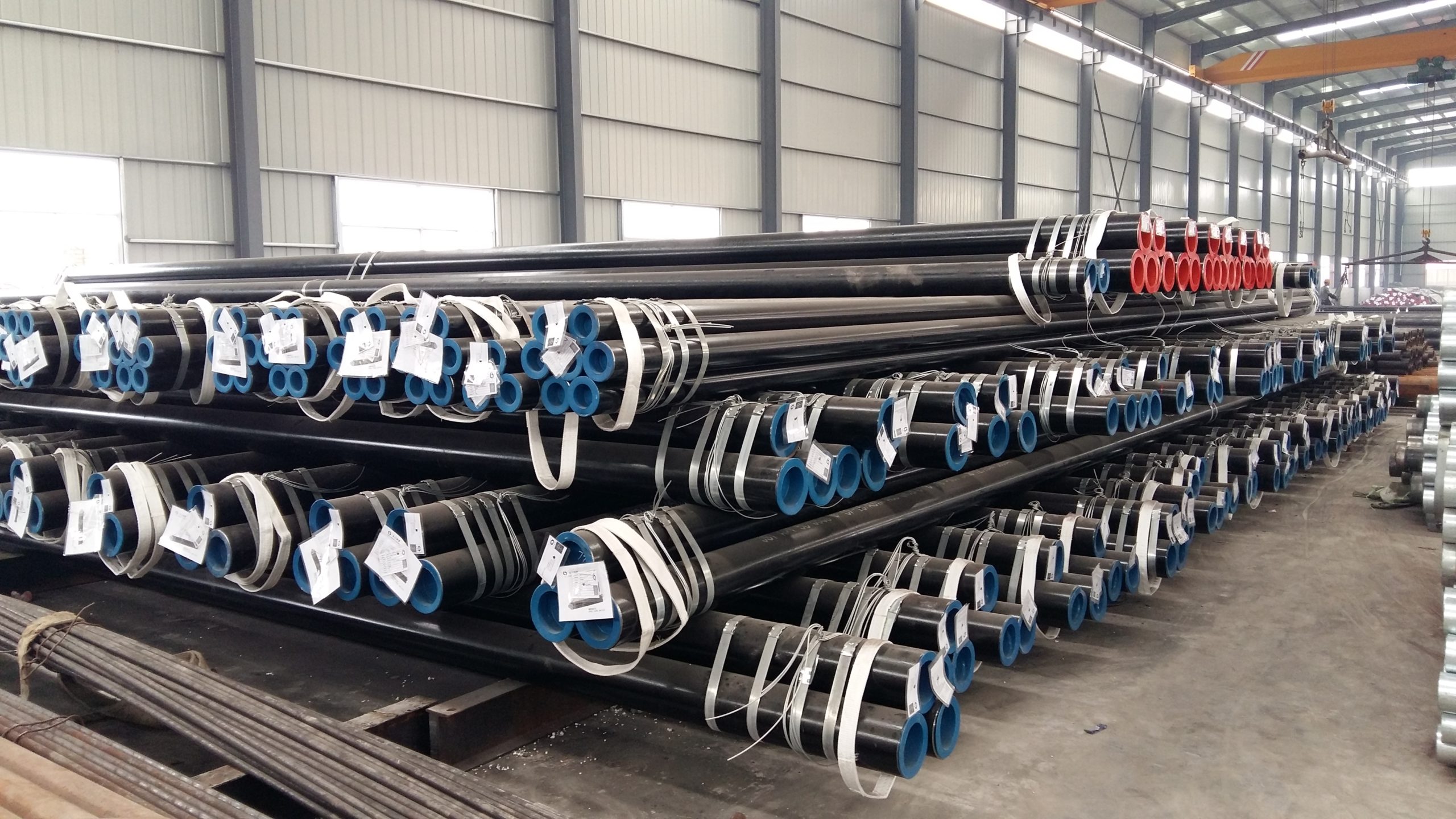

In the oil and gas industry, the use of high-quality seamless pipes is crucial for ensuring the safe and efficient transportation of fluids. API 5L, ASTM A106, and A53 Grade B seamless pipes are some of the most commonly used materials for constructing pipelines due to their excellent Mechanical properties and Corrosion resistance.

One of the key benefits of using API 5L, ASTM A106, and A53 Grade B seamless pipes is their high strength and durability. These pipes are manufactured using Hot rolling processes, which results in a uniform grain structure and improved mechanical properties. This makes them ideal for withstanding high pressure and temperature conditions, making them suitable for use in oil and gas pipelines.

Additionally, API 5L, ASTM A106, and A53 Grade B seamless pipes have excellent corrosion resistance, which is essential for ensuring the longevity of pipelines in harsh environments. These pipes are typically coated with a protective layer to prevent corrosion and rusting, further enhancing their durability and reliability.

Furthermore, the seamless design of API 5L, ASTM A106, and A53 Grade B pipes eliminates the risk of leaks and weak points that are commonly associated with welded pipes. This seamless construction also allows for a smoother flow of fluids through the pipeline, reducing friction and energy loss during transportation.

Another advantage of using API 5L, ASTM A106, and A53 Grade B seamless pipes is their versatility. These pipes are available in a wide range of sizes and thicknesses, making them suitable for various applications in the oil and gas industry. Whether it’s for transporting crude oil, natural gas, or water, these pipes can be customized to meet the specific requirements of each project.

In addition to their mechanical properties and corrosion resistance, API 5L, ASTM A106, and A53 Grade B seamless pipes are also cost-effective. The seamless manufacturing process results in higher production efficiency and lower Material wastage, leading to lower overall costs for pipeline construction.

Overall, the use of API 5L, ASTM A106, and A53 Grade B seamless pipes offers numerous benefits for oil and gas pipelines. From their high strength and durability to their corrosion resistance and cost-effectiveness, these pipes are an excellent choice for ensuring the safe and efficient transportation of fluids in the oil and gas industry.

In conclusion, API 5L, ASTM A106, and A53 Grade B seamless pipes are essential materials for constructing reliable and durable oil and gas pipelines. Their superior mechanical properties, corrosion resistance, and cost-effectiveness make them a preferred choice for engineers and project managers looking to ensure the long-term integrity of their pipelines. By investing in high-quality seamless pipes, companies can minimize the risk of leaks, reduce maintenance costs, and improve the overall efficiency of their operations.