Advantages of ASTM A192 High Pressure Seamless steel Pipe in Industrial Applications

ASTM A192 High Pressure Seamless Steel Pipe: Enhancing Industrial Applications

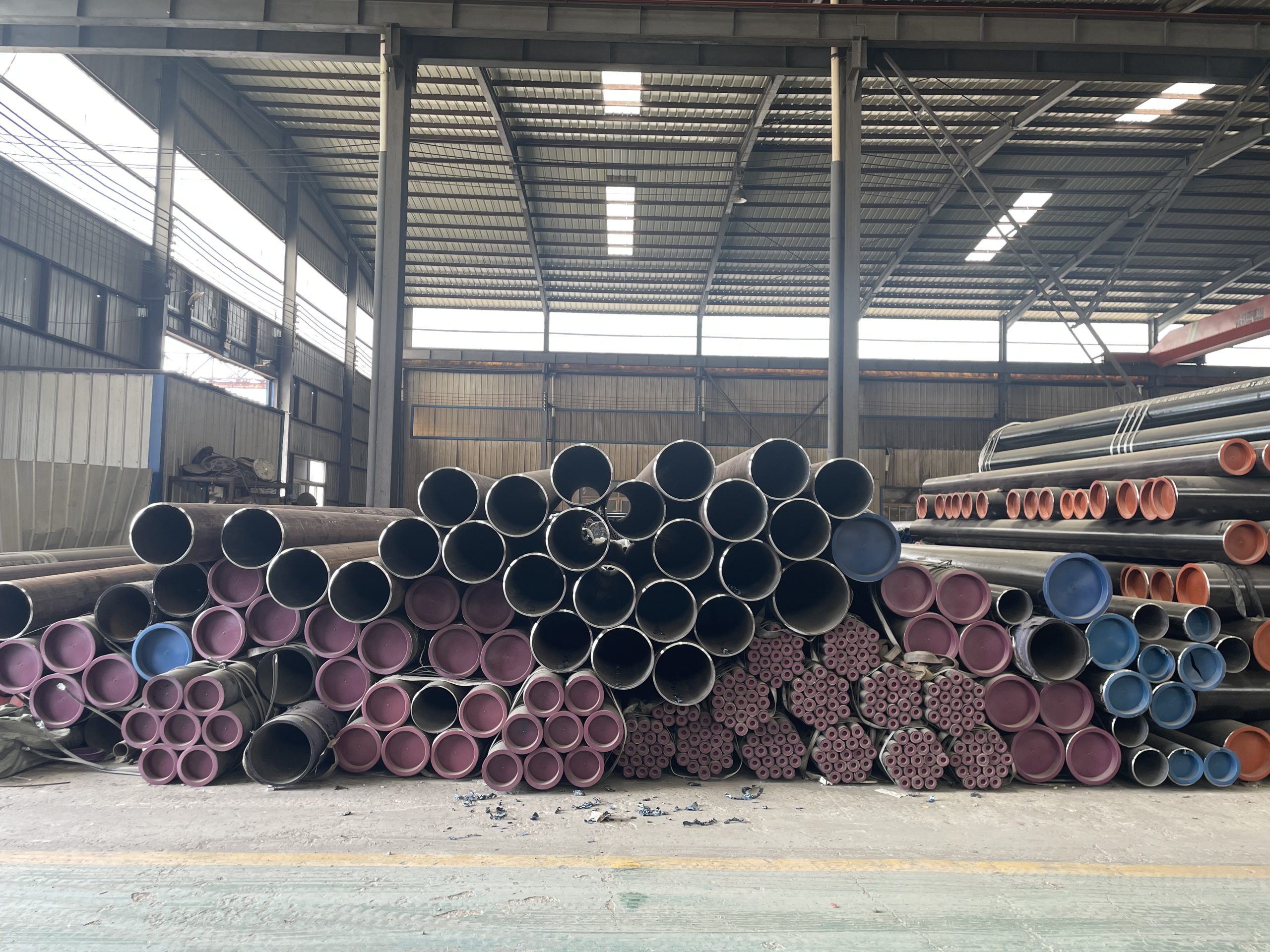

In the realm of industrial applications, the choice of materials for pipelines and infrastructure is critical to ensure optimal performance and safety. Among the various options available, ASTM A192 high-pressure seamless steel pipes stand out for their superior qualities and numerous advantages. These pipes, crafted with precision and adherence to stringent standards set by the American Society for Testing and Materials (ASTM), have become indispensable components in various industrial sectors.

One of the primary advantages of ASTM A192 high-pressure seamless steel pipes lies in their exceptional strength and durability. These pipes are manufactured using high-quality steel, which undergoes rigorous processes to ensure uniformity and structural integrity. As a result, they exhibit high Tensile strength and resistance to deformation, making them ideal for withstanding the extreme pressures and temperatures often encountered in industrial environments.

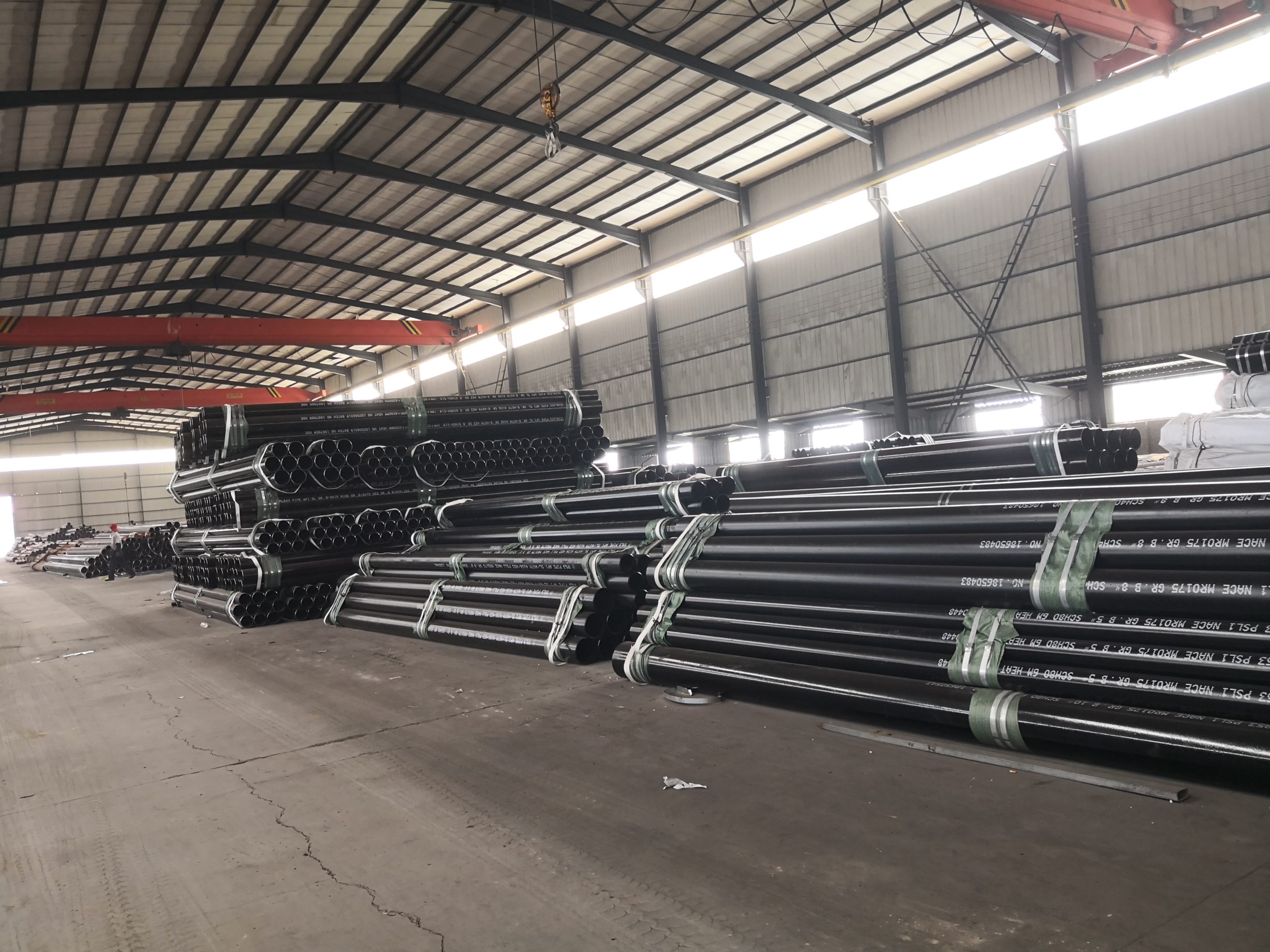

1.5 inch square steel tubingMoreover, the seamless nature of ASTM A192 pipes eliminates the need for potentially weak points such as welds or joints, which are susceptible to corrosion and leakage over time. This seamless construction not only enhances the structural integrity of the pipes but also minimizes the risk of costly maintenance and repairs, thereby contributing to overall operational efficiency and cost-effectiveness.

Furthermore, ASTM A192 high-pressure seamless steel pipes boast excellent Corrosion resistance, thanks to their composition and manufacturing processes. These pipes are typically coated with anti-corrosive materials or undergo surface treatments to protect against rust and corrosion, ensuring longevity and reliability even in harsh operating conditions. This corrosion resistance is especially crucial in industries such as petrochemicals, Oil and gas, and power generation, where exposure to corrosive substances is common.

In addition to their mechanical and chemical properties, ASTM A192 high-pressure seamless steel pipes offer unparalleled versatility and adaptability to diverse industrial applications. Whether it’s transporting fluids, gases, or steam, these pipes can handle a wide range of media with ease, making them indispensable in various processes such as refining, manufacturing, and power generation.

Moreover, ASTM A192 pipes are known for their uniform dimensions and consistent quality, which simplifies installation and ensures compatibility with existing infrastructure and equipment. This standardization not only streamlines procurement and logistics but also facilitates seamless integration into industrial systems, minimizing downtime and operational disruptions.

Another key advantage of ASTM A192 high-pressure seamless steel pipes is their environmental sustainability. These pipes are recyclable and can be reused or repurposed at the end of their service life, reducing waste and minimizing the environmental impact of industrial activities. Additionally, their durability and longevity contribute to resource conservation by reducing the need for frequent replacements and repairs.

In conclusion, ASTM A192 high-pressure seamless steel pipes offer a multitude of advantages that make them indispensable in various industrial applications. From their exceptional strength and durability to their corrosion resistance and versatility, these pipes embody reliability, efficiency, and sustainability. By choosing ASTM A192 pipes, industries can ensure the integrity and performance of their infrastructure while minimizing costs and environmental footprint. As technology advances and industrial processes evolve, the demand for high-quality materials like ASTM A192 steel pipes is only expected to grow, reaffirming their pivotal role in shaping the future of industrial engineering.