Welded vs. Seamless Stainless steel Tubing: Pros and Cons

Stainless steel tubing is a crucial component in various industries, from automotive to construction and everything in between. When it comes to choosing the right type of stainless steel tubing for your project, two primary options emerge: welded and seamless. Each type has its own set of advantages and disadvantages, which can significantly impact the performance and longevity of the final product.

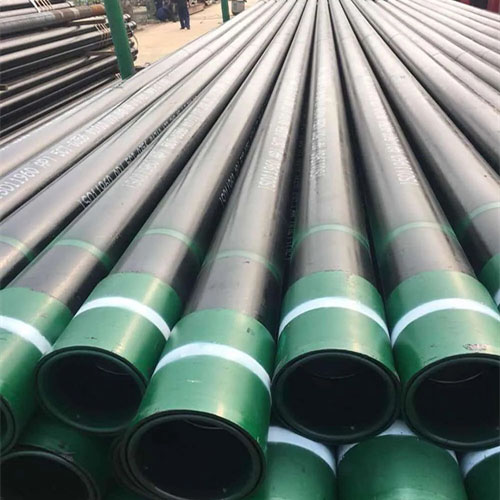

Seamless stainless steel tubing is manufactured through a process called extrusion or rotary piercing. This method involves heating a solid billet and then forcing it through a die to create a hollow tube without any seams. The seamless nature of this tubing provides several benefits, including superior Corrosion resistance and increased strength due to the absence of weld seams. Additionally, seamless tubing is often preferred for applications requiring high pressure or temperature resistance, as the lack of welds reduces the risk of weak points in the Material.

However, seamless stainless steel tubing comes with its own set of drawbacks. The manufacturing process is more complex and time-consuming than that of welded tubing, resulting in higher production costs. Additionally, seamless tubing is limited in terms of size and thickness, making it less suitable for certain applications that require larger or thicker tubes.

On the other hand, welded stainless steel tubing is created by Welding together multiple pieces of steel to form a single tube. This process offers several advantages, including lower production costs and the ability to create custom sizes and shapes to meet specific project requirements. Welded tubing is also more readily available in a wide range of diameters and wall thicknesses, making it a versatile option for various applications.

Despite its affordability and versatility, welded stainless steel tubing does have some drawbacks. The welding process introduces heat and impurities to the material, which can weaken the overall structure and reduce corrosion resistance. Additionally, the weld seam itself can become a potential weak point in the tubing, especially in applications where the tube is subjected to high pressure or stress.

In summary, both welded and seamless stainless steel tubing have their own unique set of pros and cons. The choice between the two ultimately depends on the specific requirements of the project, including factors such as budget, desired performance characteristics, and environmental conditions. For applications requiring high strength, corrosion resistance, and uniformity, seamless tubing may be the preferred option despite its higher cost. Conversely, welded tubing offers greater flexibility and affordability, making it suitable for a wide range of applications where performance requirements are less demanding.

seamless tubeUltimately, whether you opt for welded or seamless stainless steel tubing, it’s essential to work with a reputable manufacturer who can provide high-quality products that meet your exact specifications. By carefully considering the pros and cons of each option and consulting with industry experts, you can ensure that you select the right type of tubing for your project, maximizing performance and longevity while staying within budget.

Choosing the Right Stainless Steel Tubing: Factors to Consider

Choosing the right stainless steel tubing is crucial for various applications across industries. Among the key considerations is whether to opt for welded or seamless tubing. Both types offer distinct advantages and are suitable for different purposes. Understanding the differences between welded and seamless stainless steel tubing can help you make an informed decision based on your specific needs.

Welded stainless steel tubing is manufactured by welding strips of stainless steel together to form a tube. This process involves the use of heat and pressure to fuse the edges of the strip together, creating a strong bond. Welded tubing is available in a wide range of sizes and shapes, making it suitable for various applications. It is commonly used in industries such as construction, automotive, and plumbing.

One of the primary benefits of welded stainless steel tubing is its cost-effectiveness. The welding process is relatively inexpensive compared to seamless tubing production methods, making welded tubing a more economical choice for many applications. Additionally, welded tubing can be produced in large quantities, making it readily available for bulk orders and quick turnaround times.

However, welded stainless steel tubing may have some limitations compared to seamless tubing. The welding process can introduce potential weak points along the seam, which may be susceptible to corrosion or failure under certain conditions. While advancements in welding technology have improved the strength and integrity of welded tubing, it may still be less suitable for high-pressure or corrosive environments compared to seamless tubing.

On the other hand, seamless stainless steel tubing is manufactured without any welding seams. Instead, seamless tubing is produced by extruding a solid billet of stainless steel through a die to form a tube. This seamless process results in a uniform and continuous tube without any weld seams, offering superior strength and corrosion resistance compared to welded tubing.

Seamless stainless steel tubing is often preferred for critical applications where strength, reliability, and corrosion resistance are paramount. Industries such as aerospace, pharmaceuticals, and food processing commonly use seamless tubing for its high-performance characteristics. Additionally, seamless tubing is ideal for applications requiring high-pressure or high-temperature environments, where welded seams may be prone to failure.

While seamless stainless steel tubing offers superior performance in certain applications, it may also come with a higher price tag compared to welded tubing. The manufacturing process for seamless tubing is more complex and time-consuming, resulting in higher production costs. However, the added benefits of seamless tubing, such as enhanced strength and corrosion resistance, may justify the higher upfront investment for certain applications.

In conclusion, the choice between welded and seamless stainless steel tubing depends on various factors, including cost, performance requirements, and application-specific needs. Welded tubing offers cost-effectiveness and versatility, making it suitable for a wide range of applications. Meanwhile, seamless tubing provides superior strength, reliability, and corrosion resistance, making it ideal for critical applications in demanding environments. By carefully evaluating your requirements and considering the advantages and limitations of each type, you can select the right stainless steel tubing for your project.