Pros and Cons of Seamless Stainless steel Pipe

Stainless steel pipes are widely used in various industries due to their durability, Corrosion resistance, and high strength. When it comes to choosing the right type of stainless steel pipe for a specific application, two common options are seamless and ERW (Electric Resistance Welded) pipes. Both types have their own set of advantages and disadvantages, which should be carefully considered before making a decision.

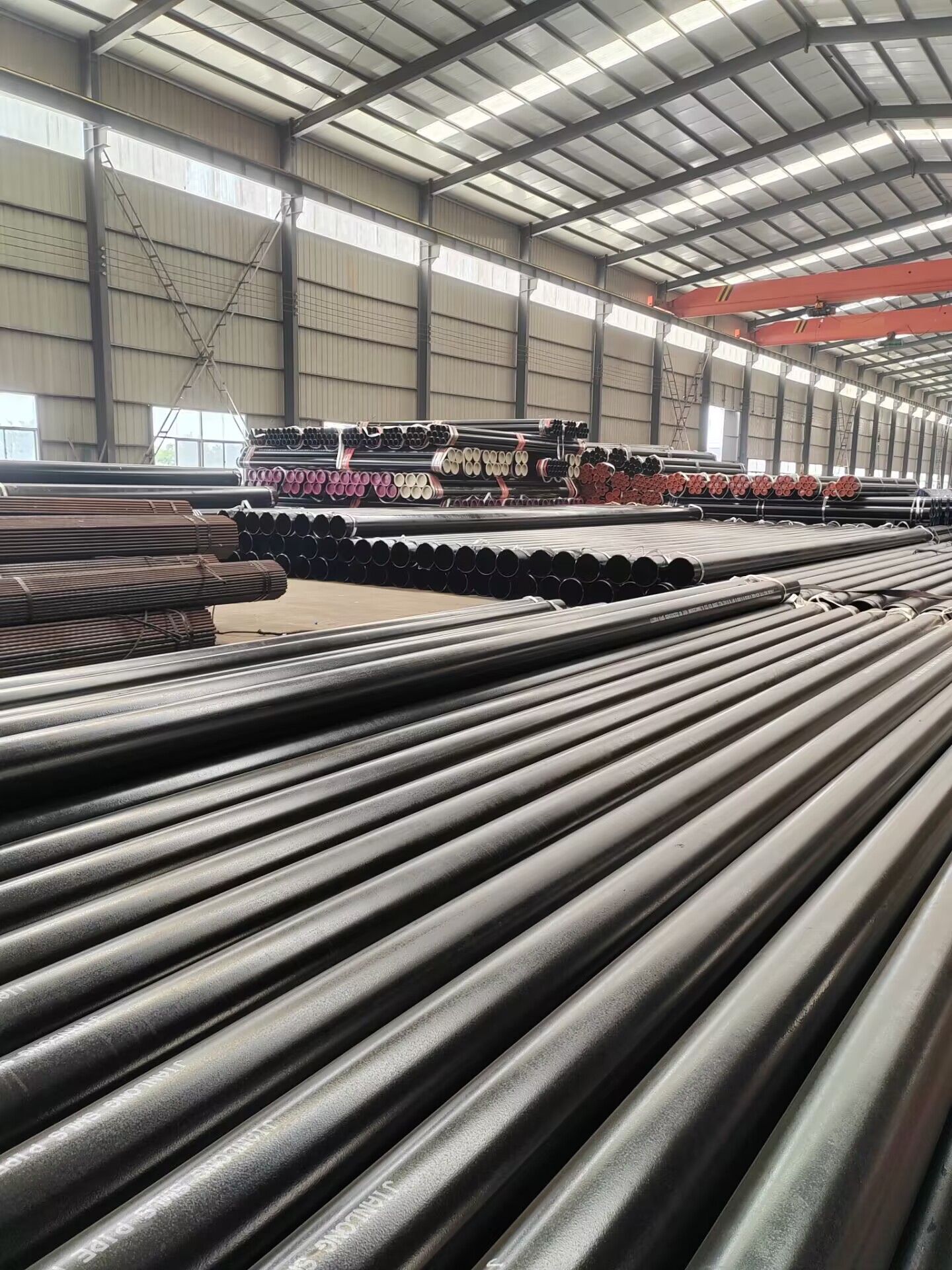

Seamless stainless steel pipes are manufactured by piercing a solid billet of stainless steel and then extruding it into a hollow tube. This process results in a pipe with no seams or welds, making it stronger and more reliable than ERW pipes. Seamless pipes are also known for their uniformity in shape and size, which ensures a tight fit when connecting multiple pipes together. Additionally, seamless pipes are less prone to corrosion and pitting, making them ideal for applications where cleanliness and hygiene are important.

On the other hand, ERW stainless steel pipes are manufactured by rolling a flat sheet of stainless steel into a cylindrical shape and then Welding the edges together using high-frequency electric currents. While ERW pipes are generally cheaper to produce than seamless pipes, they are also more susceptible to defects such as weld seams and internal stresses. These defects can weaken the pipe and make it more prone to corrosion, especially in high-pressure or high-temperature applications.

ss flex hoseOne of the main advantages of seamless stainless steel pipes is their superior strength and reliability. Because seamless pipes are made from a single piece of stainless steel, they have no weak points or potential areas of failure. This makes seamless pipes ideal for applications where safety and reliability are paramount, such as in the Oil and gas industry or in high-pressure hydraulic systems. Additionally, seamless pipes have a smoother interior surface, which reduces friction and allows for better flow of liquids or gases through the pipe.

However, seamless stainless steel pipes also have some drawbacks. One of the main disadvantages of seamless pipes is their higher cost compared to ERW pipes. The manufacturing process for seamless pipes is more complex and time-consuming, which results in a higher price tag. Additionally, seamless pipes are limited in size and thickness, which can be a drawback for certain applications that require larger or thicker pipes.

In contrast, ERW stainless steel pipes are more cost-effective and versatile than seamless pipes. ERW pipes can be produced in a wide range of sizes and thicknesses, making them suitable for a variety of applications. Additionally, ERW pipes can be easily modified or welded together to create custom lengths or shapes, which can be beneficial in certain construction or fabrication projects.

Despite their advantages, ERW stainless steel pipes also have some drawbacks. The welding process used to create ERW pipes can introduce impurities or defects into the metal, which can weaken the pipe and make it more susceptible to corrosion. Additionally, the weld seam in ERW pipes can be a potential weak point that may fail under high pressure or temperature conditions.

In conclusion, both seamless and ERW stainless steel pipes have their own set of pros and cons that should be carefully considered before making a decision. Seamless pipes are known for their superior strength and reliability, while ERW pipes are more cost-effective and versatile. Ultimately, the choice between seamless and ERW pipes will depend on the specific requirements of the application and the budget constraints of the project.

Key Differences Between ERW and Seamless Stainless Steel Pipe

Stainless steel pipes are widely used in various industries for their durability, corrosion resistance, and high strength. When it comes to choosing the right type of stainless steel pipe for a specific application, two common options are seamless and ERW (Electric Resistance Welded) pipes. While both types serve the same purpose of transporting fluids or gases, there are key differences between them that can impact their performance and suitability for different applications.

Seamless stainless steel pipes are manufactured by piercing a solid billet of stainless steel and then extruding it into a hollow tube. This process results in a pipe with no seams or welds, making it stronger and more reliable than ERW pipes. Seamless pipes are preferred for applications where high pressure, high temperature, or corrosive environments are a concern. They are also known for their uniformity in shape and size, which can be crucial in certain industries such as oil and gas, chemical processing, and power generation.

On the other hand, ERW stainless steel pipes are made by rolling a coil of steel into a cylindrical shape and then welding the seam. While ERW pipes are generally less expensive than seamless pipes, they are also less durable and have a higher risk of corrosion at the weld seam. However, ERW pipes are suitable for applications where high precision is not required, such as in plumbing, construction, and general manufacturing.

One of the main differences between seamless and ERW stainless steel pipes is their manufacturing process. Seamless pipes are produced by extruding a solid billet of stainless steel, while ERW pipes are made by welding a coil of steel. This fundamental difference in production methods results in varying Mechanical properties and performance characteristics.

Seamless stainless steel pipes have a higher strength-to-Weight ratio and are more resistant to corrosion and pressure than ERW pipes. This makes them ideal for applications that require high performance and reliability, such as in the oil and gas industry, chemical processing plants, and power generation facilities. Seamless pipes are also preferred for applications where cleanliness and hygiene are essential, such as in the food and beverage industry.

On the other hand, ERW stainless steel pipes are more cost-effective and easier to manufacture than seamless pipes. While they may not have the same level of strength and corrosion resistance as seamless pipes, ERW pipes are still suitable for a wide range of applications, including plumbing, construction, and general manufacturing. ERW pipes are also easier to customize and can be produced in a variety of sizes and shapes to meet specific requirements.

In conclusion, the choice between seamless and ERW stainless steel pipes depends on the specific requirements of the application. Seamless pipes are preferred for high-pressure, high-temperature, and corrosive environments, while ERW pipes are more cost-effective and suitable for general-purpose applications. Both types of pipes have their own advantages and limitations, so it is important to consider the specific needs of the project before making a decision.