Benefits of Using Excellent Quality Hot Selling DIP Hollow Gi Ms Round Pipe

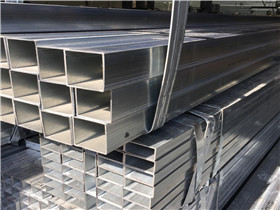

Excellent Quality Hot Selling DIP Hollow Gi Ms Round Pipe is a versatile and durable option for a wide range of applications. Whether you are in the construction industry, manufacturing sector, or simply looking for a reliable piping solution for your home, this type of pipe offers numerous benefits that make it a popular choice among professionals and DIY enthusiasts alike.

One of the key advantages of using Excellent Quality Hot Selling DIP Hollow Gi Ms Round Pipe is its exceptional strength and durability. Made from high-quality materials, these pipes are designed to withstand the rigors of everyday use, making them ideal for both indoor and outdoor applications. Whether you are building a new structure or repairing an existing one, you can trust that these pipes will provide the strength and stability you need to get the job done right.

In addition to their strength and durability, Excellent Quality Hot Selling DIP Hollow Gi Ms Round Pipes are also known for their Corrosion resistance. This is especially important in environments where exposure to moisture, chemicals, or other corrosive elements is a concern. By choosing these pipes, you can rest assured that your piping system will remain in top condition for years to come, saving you time and money on maintenance and repairs.

Another benefit of using Excellent Quality Hot Selling DIP Hollow Gi Ms Round Pipe is their versatility. Available in a variety of sizes and configurations, these pipes can be easily customized to meet the specific requirements of your project. Whether you need a straight pipe, a curved pipe, or a pipe with special fittings, you can find the perfect solution to suit your needs. This flexibility makes these pipes an excellent choice for a wide range of applications, from plumbing and HVAC systems to structural supports and decorative accents.

Furthermore, Excellent Quality Hot Selling DIP Hollow Gi Ms Round Pipes are easy to install and maintain, making them a cost-effective option for both professionals and DIY enthusiasts. With their smooth surfaces and precise dimensions, these pipes can be quickly and easily connected using standard tools and techniques. This not only saves time and labor during installation but also reduces the risk of leaks and other issues that can arise with inferior piping materials.

In conclusion, Excellent Quality Hot Selling DIP Hollow Gi Ms Round Pipes offer a wide range of benefits that make them an excellent choice for a variety of applications. From their exceptional strength and durability to their corrosion resistance and versatility, these pipes provide a reliable and cost-effective solution for all your piping needs. Whether you are a professional contractor or a homeowner looking to tackle a DIY project, you can trust that these pipes will deliver the performance and reliability you need to get the job done right.

Comparison of Welded vs. Seamless steel pipe for High-Quality Applications

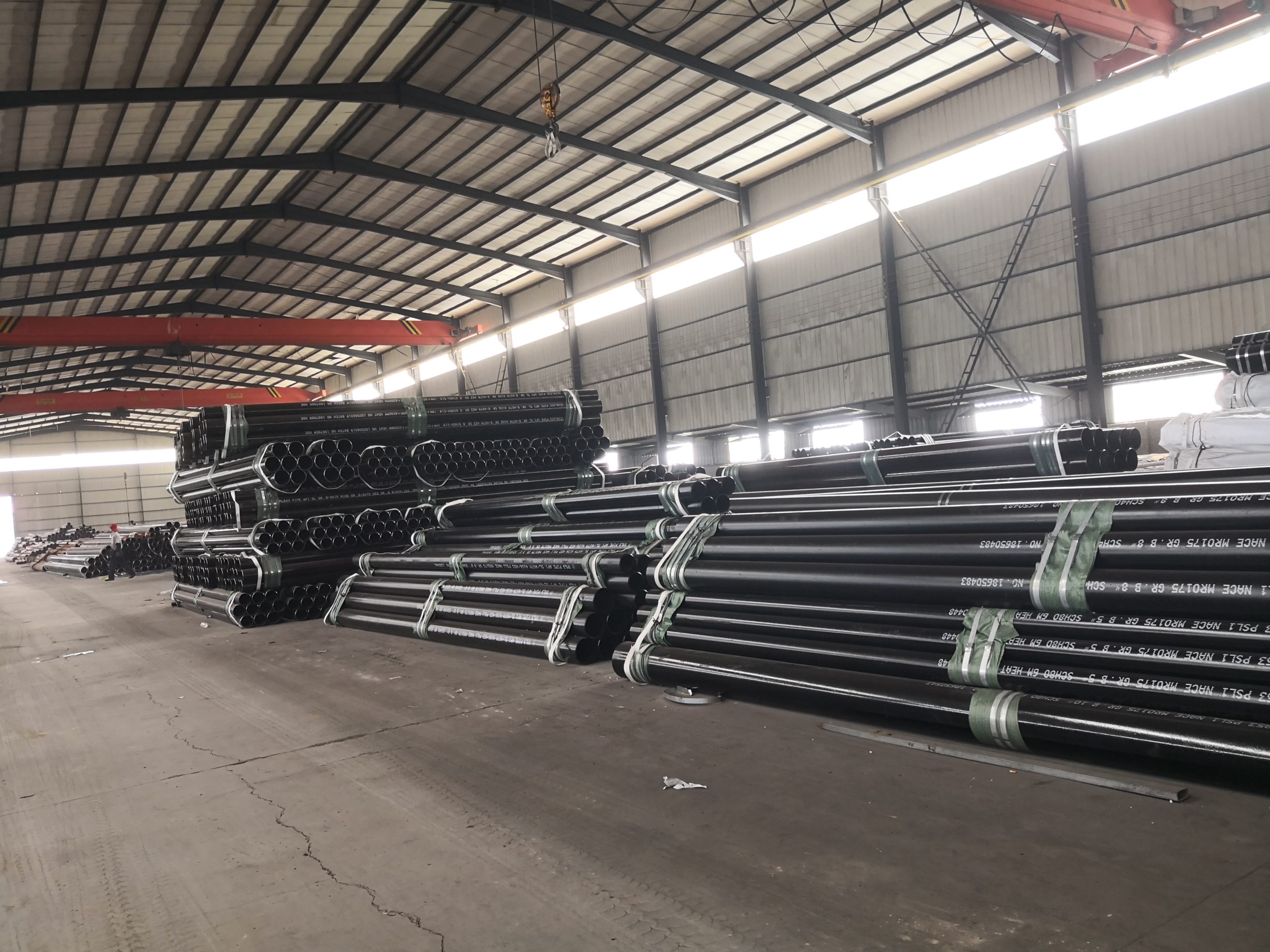

Steel pipes are an essential component in various industries, including construction, Oil and gas, and manufacturing. When it comes to choosing the right type of steel pipe for high-quality applications, two options are commonly considered: welded and seamless steel pipes. Both types have their own set of advantages and disadvantages, and understanding the differences between them is crucial in making an informed decision.

Welded steel pipes are made by Welding steel plates or coils together to form a cylindrical shape. This process involves the use of heat and pressure to bond the materials, resulting in a strong and durable pipe. Welded steel pipes are known for their cost-effectiveness and versatility, making them a popular choice for a wide range of applications. However, welded pipes may have a higher risk of defects and imperfections due to the welding process, which can affect the overall quality and performance of the pipe.

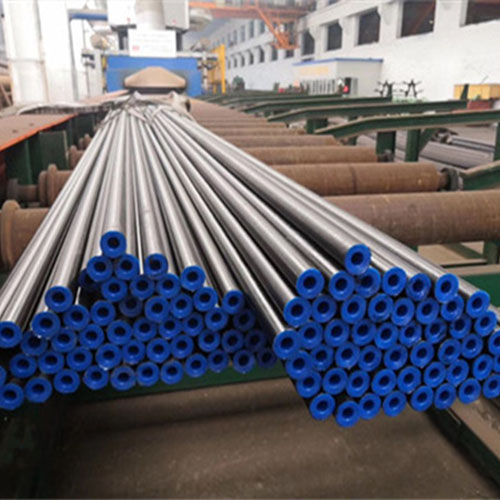

On the other hand, seamless steel pipes are made by piercing a solid steel billet to create a hollow tube without any seams or joints. This manufacturing process results in a pipe with a smooth and uniform surface, making seamless pipes ideal for high-pressure and high-temperature applications. Seamless steel pipes are known for their superior strength and reliability, as they are less prone to leaks and failures compared to welded pipes. However, seamless pipes are typically more expensive than welded pipes due to the complexity of the manufacturing process.

2.75 od exhaust pipe

When it comes to high-quality applications, the choice between welded and seamless steel pipes ultimately depends on the specific requirements of the project. Welded pipes are suitable for applications where cost is a primary concern, and the risk of defects can be mitigated through proper quality control measures. On the other hand, seamless pipes are preferred for critical applications where strength, reliability, and performance are paramount.

In terms of performance, seamless steel pipes have a clear advantage over welded pipes. The absence of seams and joints in seamless pipes eliminates weak points that are susceptible to failure under high pressure or temperature conditions. Seamless pipes also have a higher Tensile strength and Yield strength compared to welded pipes, making them more durable and long-lasting in demanding environments.

Another important factor to consider when choosing between welded and seamless steel pipes is the ease of installation and maintenance. Welded pipes are typically easier to install and repair due to their flexibility and adaptability. In contrast, seamless pipes may require specialized equipment and expertise for installation and maintenance, which can increase the overall cost and complexity of the project.

In conclusion, both welded and seamless steel pipes have their own set of advantages and disadvantages when it comes to high-quality applications. Welded pipes are cost-effective and versatile, while seamless pipes offer superior strength and reliability. The choice between the two types of pipes ultimately depends on the specific requirements of the project, including budget, performance, and ease of installation. By understanding the differences between welded and seamless steel pipes, you can make an informed decision that meets the needs of your project and ensures long-lasting performance and durability.