Benefits of Factory Direct Sales for Seamless Low Carbon steel Pipe

Factory direct sales have become increasingly popular in the manufacturing industry, offering numerous benefits for both businesses and consumers. When it comes to seamless low carbon steel pipes, opting for factory direct sales can provide a range of advantages that make it a preferred choice for many buyers.

One of the key benefits of factory direct sales for seamless low carbon steel pipes is cost savings. By eliminating the middleman and purchasing directly from the manufacturer, buyers can enjoy lower prices and better value for their money. This is particularly advantageous for businesses that require a large volume of steel pipes for their operations, as the savings can add up significantly over time.

In addition to cost savings, factory direct sales also offer greater control over the quality of the products being purchased. When buying from a manufacturer, buyers can have direct communication with the production team and ensure that their specific requirements are met. This level of customization and quality control is often not possible when purchasing through a distributor or retailer.

Furthermore, factory direct sales can lead to faster delivery times and improved customer service. With direct access to the manufacturer, buyers can receive real-time updates on their orders and address any issues or concerns promptly. This streamlined communication process can help to avoid delays and ensure a smooth and efficient purchasing experience.

Another advantage of factory direct sales for seamless low carbon steel pipes is the ability to access a wider range of products and options. Manufacturers often have a larger inventory and can offer more customization options than distributors or retailers. This means that buyers can find the exact specifications they need for their projects, without having to compromise on quality or design.

Moreover, factory direct sales can also lead to a more sustainable and environmentally friendly purchasing process. By reducing the number of intermediaries involved in the supply chain, buyers can minimize the carbon footprint associated with their purchases. This can be particularly important for businesses that are looking to reduce their environmental impact and operate in a more sustainable manner.

Overall, factory direct sales for seamless low carbon steel pipes offer a range of benefits that make them a smart choice for buyers. From cost savings and quality control to faster delivery times and a wider range of options, purchasing directly from the manufacturer can help businesses streamline their operations and achieve their goals more efficiently.

In conclusion, factory direct sales for seamless low carbon steel pipes provide numerous advantages that make them a preferred choice for many buyers. By cutting out the middleman, buyers can enjoy cost savings, quality control, faster delivery times, and a wider range of products and options. Additionally, factory direct sales can lead to a more sustainable purchasing process, making them a smart choice for businesses looking to operate in a more environmentally friendly manner.

Comparison of Sch80 SS400 S235JR Q345 Q195 and Sch40 St37 St52 Hot Rolled Seamless Pipes

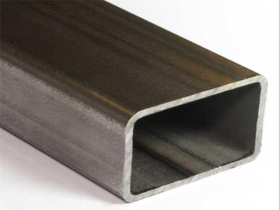

When it comes to choosing the right Seamless steel pipe for your project, there are several factors to consider. Two popular options on the market are Sch80 SS400 S235JR Q345 Q195 and Sch40 St37 St52 hot rolled seamless pipes. Both types of pipes have their own unique characteristics and advantages, so it’s important to understand the differences between them before making a decision.

Sch80 SS400 S235JR Q345 Q195 seamless pipes are known for their high strength and durability. These pipes are made from low carbon steel, which makes them ideal for applications that require a strong and reliable Material. The Sch80 designation indicates that these pipes have a thicker Wall thickness compared to Sch40 pipes, making them suitable for high-pressure and high-temperature applications.

On the other hand, Sch40 St37 St52 hot rolled seamless pipes are also popular in the industry for their versatility and cost-effectiveness. These pipes are made from a combination of carbon and manganese, which gives them good Mechanical properties and weldability. The St37 and St52 designations refer to the grade of steel used in the pipes, with St52 being a higher grade that offers better strength and Corrosion resistance.

One of the key differences between Sch80 SS400 S235JR Q345 Q195 and Sch40 St37 St52 seamless pipes is their wall thickness. Sch80 pipes have a thicker wall compared to Sch40 pipes, which makes them more suitable for applications that require higher pressure and temperature ratings. However, this also means that Sch80 pipes are heavier and more expensive than Sch40 pipes.

In terms of material composition, Sch80 SS400 S235JR Q345 Q195 seamless pipes are made from low carbon steel, which offers excellent strength and toughness. These pipes are commonly used in construction, Oil and gas, and automotive industries where high strength and durability are required. On the other hand, Sch40 St37 St52 hot rolled seamless pipes are made from a combination of carbon and manganese, which provides good mechanical properties and weldability. These pipes are often used in structural applications, such as building construction and machinery manufacturing.

When it comes to cost, Sch40 St37 St52 seamless pipes are generally more affordable than Sch80 SS400 S235JR Q345 Q195 pipes. This makes them a popular choice for projects with budget constraints or where high-pressure ratings are not required. However, it’s important to consider the specific requirements of your project before making a decision, as the cost difference may be outweighed by the performance benefits of Sch80 pipes.

a500 pipe

In conclusion, both Sch80 SS400 S235JR Q345 Q195 and Sch40 St37 St52 hot rolled seamless pipes have their own unique advantages and applications. The choice between the two will ultimately depend on the specific requirements of your project, such as pressure ratings, temperature resistance, and budget constraints. By understanding the differences between these two types of pipes, you can make an informed decision that meets the needs of your project.