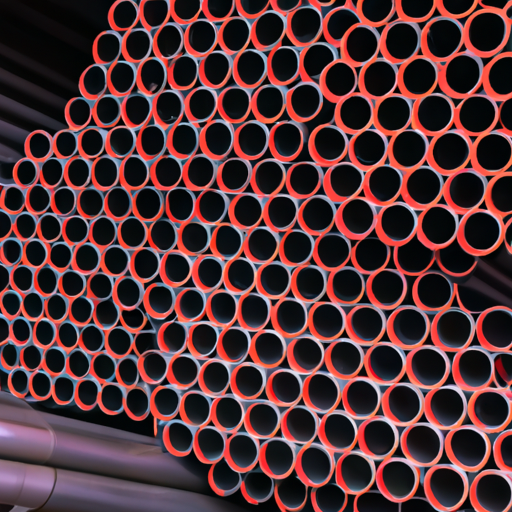

Benefits of Using Capillary Stainless steel Seamless Round Welded Pipe in Industrial Applications

Capillary stainless steel seamless round welded pipes are a crucial component in various industrial applications due to their numerous benefits. These pipes are known for their durability, Corrosion resistance, and high strength, making them ideal for use in industries such as Oil and gas, chemical processing, and automotive manufacturing.

https://youtube.com/watch?v=4erHivkeuv4

One of the key advantages of using capillary stainless steel seamless round welded pipes is their ability to withstand high temperatures and pressures. This makes them suitable for applications where the pipes are exposed to extreme conditions, such as in steam boilers or heat exchangers. The seamless construction of these pipes ensures that there are no weak points or joints that could potentially fail under pressure, providing a reliable and long-lasting solution for industrial piping systems.

In addition to their strength and durability, capillary stainless steel seamless round welded pipes are also highly resistant to corrosion. This is particularly important in industries where the pipes come into contact with corrosive substances, such as acids or chemicals. The stainless steel Material used in these pipes contains chromium, which forms a protective oxide layer on the surface of the pipe, preventing rust and corrosion from developing. This corrosion resistance extends the lifespan of the pipes and reduces the need for frequent maintenance or replacement.

Furthermore, capillary stainless steel seamless round welded pipes are known for their smooth interior surface, which allows for efficient fluid flow. The seamless construction of these pipes eliminates the need for additional fittings or joints, reducing the risk of leaks and pressure drops in the system. This smooth surface also minimizes frictional resistance, allowing for a more efficient transfer of fluids through the piping system. As a result, industries can benefit from improved energy efficiency and reduced operating costs when using capillary stainless steel seamless round welded pipes.

Another advantage of using capillary stainless steel seamless round welded pipes is their versatility and adaptability to different applications. These pipes come in a variety of sizes, thicknesses, and grades to meet the specific requirements of each industrial project. Whether it is for transporting liquids, gases, or solids, capillary stainless steel seamless round welded pipes can be customized to suit the needs of the application. Additionally, these pipes can be easily welded or bent to create complex piping configurations, making them a flexible and cost-effective solution for a wide range of industrial projects.

24 inch steel pipe

In conclusion, capillary stainless steel seamless round welded pipes offer numerous benefits for industrial applications, including high strength, corrosion resistance, smooth fluid flow, and versatility. These pipes provide a reliable and long-lasting solution for piping systems in industries such as oil and gas, chemical processing, and automotive manufacturing. By choosing capillary stainless steel seamless round welded pipes, industries can ensure the efficient and safe operation of their systems while reducing maintenance costs and downtime.

How to Choose the Right Seamless steel pipe for Your Project

When it comes to choosing the right seamless steel pipe for your project, there are several factors to consider. Seamless steel pipes are widely used in various industries due to their durability, strength, and resistance to corrosion. However, with so many options available in the market, it can be overwhelming to make the right choice. In this article, we will discuss the key considerations to keep in mind when selecting a capillary stainless steel seamless round welded pipe.

One of the first things to consider when choosing a seamless steel pipe is the material. Stainless steel is a popular choice for many applications due to its corrosion resistance and high strength. When selecting a stainless steel seamless pipe, it is important to consider the grade of stainless steel. The most common grades of stainless steel used in seamless pipes are 304 and 316. Grade 304 stainless steel is suitable for general applications, while grade 316 stainless steel is recommended for applications where corrosion resistance is a priority.

Another important factor to consider when choosing a seamless steel pipe is the size and thickness. Seamless steel pipes are available in a wide range of sizes and thicknesses to suit different applications. It is essential to determine the required size and thickness of the pipe based on the specific requirements of your project. The size of the pipe will depend on factors such as the flow rate, pressure, and temperature of the fluid being transported.

In addition to material, size, and thickness, it is crucial to consider the manufacturing process of the seamless steel pipe. Seamless steel pipes are manufactured using two main processes: Hot rolling and cold drawing. Hot rolling involves heating the steel billet to high temperatures and then rolling it into a seamless pipe. Cold drawing, on the other hand, involves pulling the steel billet through a die to form a seamless pipe. Each manufacturing process has its advantages and disadvantages, so it is important to choose the right process based on the requirements of your project.

Furthermore, it is essential to consider the surface finish of the seamless steel pipe. The surface finish of the pipe can affect its appearance, corrosion resistance, and durability. Common surface finishes for seamless steel pipes include mill finish, polished finish, and brushed finish. The choice of surface finish will depend on the aesthetic requirements and environmental conditions of your project.

When selecting a capillary stainless steel seamless round welded pipe, it is also important to consider the certification and quality standards. Ensure that the seamless steel pipe meets the relevant industry standards and certifications to guarantee its quality and performance. Look for reputable manufacturers who adhere to strict quality control measures to ensure the reliability of the seamless steel pipe.

In conclusion, choosing the right seamless steel pipe for your project requires careful consideration of various factors such as material, size, thickness, manufacturing process, surface finish, and quality standards. By taking these factors into account, you can select a capillary stainless steel seamless round welded pipe that meets your project requirements and delivers optimal performance.